1911 Encyclopædia Britannica/Steam Engine

STEAM ENGINE, 1. A steam engine is a machine for the conversion of heat into mechanical work, in which the working substance is water and water vapour. The working substance may be regarded from two points of view. Thermodynamically it is the vehicle by which heat is conveyed to and through the engine from the hot source (the furnace and boiler). Part of this heat suffers a transformation into work as it passes through, and the remainder is rejected, still in the form of heat. Mechanically the working substance is a medium capable of exerting pressure, which effects this transformation in doing work by means of the changes of volume which it undergoes in the operation of the machine. Regarded as a thermodynamic device, the function of the engine is to get as much work as possible from a given quantity of heat or, to go a step further back, from the combustion of a given quantity of fuel. Accordingly, a question of primary importance is what is called the efficiency of the engine, which is the ratio of the work done to the heat supplied. Before, however, proceeding to discuss the steam engine in this aspect, or treating of the mechanics of its modern forms, it may be useful to give a brief historical sketch of its early development as an industrial appliance. In any such sketch the chief share of attention must necessarily be given to the work of James Watt. But a process of evolution had been going on before the time of Watt which prepared the steam engine for the immense improvements it received at his hands. His labours stand in natural sequence to those of Thomas Newcomen, and Newcomen’s to those of Denis Papin and Thomas Savery. Savery’s engine in its turn was the reduction to practical form of a contrivance which had long before been known as a scientific toy. The most modern type of all, the steam turbine of C. A. Parsons, is a new departure which has but little to connect it directly with the past; but even the steam turbine not only profits by the inventions of Watt, but in its characteristic feature finds crude prototypes in apparatus which employed the kinetic energy of jets of steam.

Fig. 1.—Hero’s Apparatus, 130 B.C.

2. One of these, indeed, is

mentioned amongst the earliest

notices we

have of any heat

engine. In the Pneumatica

of Hero of Alexandria (c.

130 B.C.) there is described

the aeolipile, which is a

Hero, 130

B.C. primitive steam reaction turbine,

consisting of a spherical

vessel pivoted on a central

axis and supplied with steam

through one of the pivots. The steam escapes by bent pipes

facing tangentially in opposite directions, at opposite ends of

a diameter perpendicular to the axis. The globe revolves by

reaction from the escaping steam just as a Barker’s mill is

driven by escaping water. Another apparatus described by

Hero (fig. 1)[1] is interesting as the prototype of a class of engines which long afterwards became practically important. A hollow altar containing air is heated by a fire kindled on it; the air in expanding drives some of the water contained in a spherical

vessel beneath the altar into a bucket, which descends and

opens the temple doors above by pulling round a pair of

vertical posts to which the doors are fixed. When the fire is

extinguished the air cools, the water leaves the bucket, and the

doors close. In another device a jet of water driven out by

expanding air is turned to account as a fountain.

3. From the time of Hero to the 17th century there is no progress to record, though here and there we find evidence that appliances like those described by Hero were used for trivial purposes, such as organ-blowing and the Della Porta, 1601 turning of spits. The next distinct step was the publication in 1601 of a treatise on pneumatics by Giovanni Battista della Porta, in which he shows an apparatus similar to Herb’s fountain, but with steam instead of air as the displacing fluid. Steam generated in a separate vessel passes into a closed chamber containing water, from which a pipe (open under the water) leads out. He also points out that the condensation of steam in the closed chamber may be used to produce a vacuum and suck up water from a lower level. In fact, his suggestions anticipate very fully the engine which a century later became in the hands of Savery the earliest commercially successful steam engine. In 1615 Solomon de Caus gives a plan of forcing up water by a steam fountain which differs from Della Porta’s only in having one vessel serve both as boiler and as displacement-chamber, the hot water being itself raised.

4. Another line of invention was taken by Giovanni Branca (1629), who designed an engine shaped like a water-wheel, to be driven by the impact of a jet of steam on its vanes, and in its turn to drive other mechanism for various useful purposes. But Branca’s suggestion was for the time unproductive, and we find the course of invention reverting to the line followed by Della Porta and De Caus.

5. The next contributor is one whose place is not easily assigned. To Edward Somerset, second marquis of Worcester, appears to be due the credit of proposing, if not making, the first useful steam engine. Its object Marquis of Worcester, 1663. was to raise water, and it worked probably like Della Porta’s model, but with a pair of displacement-chambers, from each of which alternately water was forced by steam from an independent boiler, or perhaps by applying heat to the chamber itself, while the other vessel was allowed to refill. Lord Worcester’s description of the engine in art. 68 of his Century of Inventions (1663) is obscure, and no drawings are extant. It is, therefore, difficult to say whether there were any distinctly novel features except the double action; in particular, it is not clear whether the suction of a vacuum was used to raise water as well as the direct pressure of steam.

6. The steam engine first became commercially successful in

the hands of Thomas Savery,[2] who, in 1698, obtained a patent for

a water-raising engine, shown in fig. 2. Steam is

admitted to one of the oval vessels A, displacing

Savery,

1698.

water, which it drives up through the check-valve

B. When the vessel A is emptied of water the supply of

steam is stopped, and the steam already there is condensed

by allowing a jet of cold water from a cistern above to stream

over the outer surface of the vessel. This produces a vacuum

and causes water to be sucked up through the pipe C and

the valve D. Meanwhile steam has been displacing water

Fig. 2.—Savery’s Pumping Engine, 1698.

from the other vessel, and is ready to be condensed there. The valves B and D open only upwards. The supplementary boiler and furnace E are for feeding water to the main boiler; E is filled while cold and a fire is lighted under it; it then acts like the vessel of De Gaus in forcing a supply of feed-water into the main boiler F. The gauge cocks G, G are an interesting feature in detail. Another form of Savery’s engine had only one displacement-chamber and worked intermittently. In the use of artificial means to condense the steam, and in the application of the vacuum so formed to raise water by suction from a level lower than that of the engine, Savery’s engine was probably an improvement on Worcester’s; in any case it found what Worcester’s engine had failed to find—considerable employment in pumping mines and in raising water to supply houses and towns, and even to drive water-wheels. A serious difficulty which prevented its general use in mines was the fact that the height through which it would lift water was limited by the pressure the boiler and vessels could bear. Pressures as high as 8 or 10 atmospheres were employed—and that, too, without a safety-valve—but Savery found it no easy matter to deal with high-pressure steam; he complains that it melted his common solder, and forced him, as Desaguliers tells us, “to be at the pains and charge to have all his joints soldered with spelter.” Apart from this drawback, the waste of fuel was enormous, from the condensation of steam which took place on the surface of the water and on the sides of the displacement-chamber at each stroke; the consumption of coal was, in proportion to the work done, some twenty times greater than in a good modern steam engine. In a tract called The Miner’s Friend Savery alludes thus to the alternate heating and cooling of the water-vessel: “On the outside of the vessel you may see how the water goes out as well as if the vessel were transparent, for so far as the steam continues within the vessel so far is the vessel dry without and so very hot as scarce to endure the least touch of the hand. But as far as the water is, the said vessel will be cold and wet where any water has fallen on it; which cold and moisture vanishes as fast as the steam in its descent takes the place of the water.” Before Savery’s engine was entirely displaced by its successor, Newcomen’s, it was improved by J. T. Desaguliers, who applied to it the safety valve (invented by Papin), and substituted condensation by a jet of cold water within the vessel for the surface condensation used by Savery. To Savery is ascribed the first use of the term “horse power” as a measure of the performance of an engine.

7. So early as 1678 the use of a piston and cylinder (long

before known as applied to pumps) in a heat-engine had been

suggested by Jean de Hautefeuille, who proposed

and to use the explosion of gun-powder either to raise a

piston or to force up water, or to produce, by the subsequent

cooling of the gases, a partial vacuum into

Cylinder

and Piston Engine.

which water might be sucked up. Two years later Christian

Huygens described an engine in which the explosion of gunpowder

in a cylinder expelled part of the gaseous contents, after

which the cooling of the remainder caused a piston to descend

under atmospheric pressure, and the piston in descending did

work by raising a weight.

8. In 1690 Denis Papin, who ten years before had invented the safety-valve as an adjunct to his “digester,” suggested that the condensation of steam should be employed to make a vacuum under a piston previously raised by the expansion of the steam. Papin’s was the earliest cylinder and piston steam engine, and his plan of using steam Papin. was that which afterwards took practical shape in the atmospheric engine of Newcomen. But his scheme was made unworkable by the fact that he proposed to use but one vessel as both boiler and cylinder. A small quantity of water was placed at the bottom of a cylinder and heat was applied. When the piston had risen the fire was removed, the steam was allowed to cool, and the piston did work in its down-stroke under the pressure of the atmosphere. After hearing of Savery’s engine in 1705 Papin turned his attention to improving it, and devised a modified form, shown in fig. 3, in which the displacement-chamber A was a cylinder, with a floating diaphragm or piston on the top of the water to keep the water and steam from direct contact with one another. The water was delivered into a closed air-vessel B, from which it issued in a continuous stream, against the vanes of a water-wheel. After the steam had done its work in the displacement-chamber it was allowed to escape by the stop-cock C instead of being condensed. Papin's engine was, in fact, a non-condensing single-acting steam pump, with steam cylinder and pump cylinder in one. A curious feature of it was the heater D, a hot mass of metal placed in the diaphragm for the purpose of keeping the steam dry. Among the many inventions of Papin was a boiler with an internal fire-box—the earliest example of a construction that is now almost universal.[3]

9. While Papin was thus going back from his first notion

of a piston engine to Savery’s cruder type, a new inventor

had appeared who made the piston engine a practical

success by separating the boiler from the cylinder

and by using (as Savery had done) artificial means

to condense the steam. This was Thomas Newcomen,

Newcomen’s Atmospheric Engine, 1705.

Fig. 4.—Newcomen’s Atmospheric Engine, 1705.

who in 1705, with his assistant, John Cawley,

gave the steam engine

the form shown in fig. 4.

Steam admitted from

the boiler to the cylinder

allowed the piston

to be raised by a heavy

counterpoise on the other

side of the beam. Then

the steam valve was

shut and a jet of cold

water entered the cylinder

and condensed the

steam. The piston was

consequently forced

down by the pressure of

the atmosphere and did

work on the pump. The

next entry of steam

expelled the condensed

water from the cylinder through an escape valve. The piston was kept tight by a

layer of water on its upper surface. Condensation was at first

effected by cooling the outside of the cylinder, but the accidental

leakage of the packing water past the piston showed the advantage

of condensing by a jet of injection water, and this plan

took the place of surface condensation. The engine used steam

whose pressure was little if at all greater than that of the atmosphere;

sometimes, indeed, it was worked with the manhole lid

off the boiler.

10. About 1711 Newcomen’s engine began to be introduced for pumping mines. It is doubtful whether the action was originally automatic, or depended on the periodical turning of taps by an attendant. The common story is that in 1713 a boy named Humphrey Potter, whose duty it was to open and shut the valves of an engine Self-acting Valve-gear. he attended, made the engine self-acting by causing the beam itself to open and close the valves by suitable cords and catches. This device was simplified in 1718 by Henry Beighton, who suspended from the beam a rod called the plug-tree, which worked the valves by means of tappets. By 1725 the engine was in common use in collieries, and it held its place without material change for about three-quarters of a century in all. Near the close of its career the atmospheric engine was much improved in its mechanical details by John Smeaton, who built many large engines of this type about the year 1770, just after the great step which was to make Newcomen’s engine obsolete had been taken by James Watt.

Compared with Savery’s engine, Newcomen’s had (as a pumping engine) the great advantage that the intensity of pressure in the pumps was not in any way limited by the pressure of the steam. It shared with Savery’s, in a scarcely less degree, the defect already pointed out, that steam was wasted by the alternate heating and cooling of the vessel into which it was led. Though obviously capable of more extended uses, it was in fact almost exclusively employed to raise water—in some instances for the purpose of turning water-wheels to drive other machinery. Even contemporary writers complain of its vast “consumption of fuel,” which appears to have been scarcely smaller than that of the engine of Savery.

11. In 1763 James Watt, an instrument maker in Glasgow,

while engaged by the university in repairing a model of Newcomen’s

engine, was struck with the waste of steam

to which the alternate chilling and heating of the

cylinder gave rise. He saw that the remedy, in his

own words, would lie in keeping the cylinder as hot as the steam

Watt,

1763.

that entered it. With this view he added to the engine a new

organ—an empty vessel separate from the cylinder, into which

the steam should be allowed to escape from the cylinder, to be

condensed there by the application of cold water either outside

or as a jet. To preserve the vacuum in his condenser he added

Fig. 5.—Watt’s Experimental Apparatus.

a pump called the air-pump, whose

function was to pump from it the

condensed steam and water of condensation,

as well as the air which

would otherwise accumulate by leakage

or by being brought in with the

steam or with the injection water.

Then, as the cylinder was no longer

used as a condenser, he was able to

keep it hot by clothing it with non-conducting

bodies, and in particular

by the use of a steam jacket, or layer

of hot steam between the cylinder

and an external casing. Further, and still with the same

object, he covered in the top of the cylinder, taking the piston-rod

out through a steam-tight stuffing-box, and allowed steam

instead of air to press upon the piston’s upper surface. The

idea of using a separate condenser had no sooner occurred to

Watt than he put it to the test by constructing the apparatus

shown in fig. 5. There A is the cylinder, B a surface condenser,

and C the air-pump. The cylinder was filled with steam above

the piston, and a vacuum was formed in the surface condenser B.

On opening the stop-cock D the steam rushed over from the

cylinder and was condensed, while the piston rose and lifted a

weight. After several trials Watt patented his improvements

in 1769; they are described in his specification in the following

words, which, apart from their immense historical interest,

deserve careful study as a statement of principles which to this

day guide the scientific development of the steam engine:—

“My method of lessening the consumption of steam, and consequently fuel, in fire-engines, consists of the following principles:—

“First, That vessel in which the powers of steam are to be employed to work the engine, which is called the cylinder in common fire-engines, and which I call the steam-vessel, must, during the whole time the engine is at work, be kept as hot as the steam that enters it; first by enclosing it in a case of wood, or any other materials that transmit heat slowly; secondly, by surrounding it with steam or other heated bodies; and, thirdly, by suffering neither water nor any other substance colder than the steam to enter or touch it during that time.

“Secondly, In engines that are to be worked wholly or partially by condensation of steam, the steam is to be condensed in vessels distinct from the steam-vessels or cylinders, although occasionally communicating with them; these vessels I call condensers; and, whilst the engines are working, these condensers ought at least to be kept as cold as the air in the neighbourhood of the engines, by application of water or other cold bodies.

“Thirdly, Whatever air or other elastic vapour is not condensed by the cold of the condenser, and may impede the working of the engine, is to be drawn out of the steam-vessels or condensers by means of pumps, wrought by the engines themselves, or otherwise.

“Fourthly, I intend in many cases to employ the expansive force of steam to press on the pistons, or whatever may be used instead of them, in the same manner in which the pressure of the atmosphere is now employed in common fire-engines. In cases where cold water cannot be had in plenty, the engines may be wrought by this force of steam only, by discharging the steam into the air after it has done its office. . . .

“Sixthly, I intend in some cases to apply a degree of cold not capable of reducing the steam to water, but of contracting it considerably, so that the engines shall be worked by the alternate expansion and contraction of the steam.

“Lastly, Instead of using water to render the pistons and other parts of the engine air and steam tight, I employ oils, wax, resinous bodies, fat of animals, quicksilver and other metals in their fluid state.”

The fifth claim was for a rotary engine, and need not be quoted here.

The “common fire engine” alluded to was the steam engine, or, as it was more generally called, the “atmospheric” engine of Newcomen. Enormously important as Watt’s first patent was, it resulted for a time in the production of nothing more than a greatly improved engine of the Newcomen type, much less wasteful of fuel, able to make faster strokes, but still only suitable for pumping, still single-acting, with steam admitted during the whole stroke, the piston, as before, pulling the beam by a chain working on a circular arc. The condenser was generally worked by injection, but Watt has left a model of a surface condenser made up of small tubes, in every essential respect like the condensers now used in marine engines.[4]

12. Fig. 6 is an example of the Watt pumping engine of this period. It should be noticed that, although the top of the cylinder is closed and steam has access to the upper side of the piston, this is done only to keep the cylinder and piston warm. The engine is still single-acting; the steam in the upper side merely plays the part which was played in Newcomen’s engine by the atmosphere; and it is Watt’s Pumping Engine, 1769. the lower end of the cylinder alone that is ever put in communication with the condenser. There are three valves: the “steam” valve 𝑎, the “equilibrium” valve 𝑏, and the “exhaust” valve 𝑐. At the beginning of the down-stroke 𝑐 is opened to produce a vacuum below the piston and 𝑎 is opened to admit steam above it. At the end of the down-stroke 𝑎 and 𝑐 are shut and 𝑏 is opened. This puts the two sides in equilibrium and allows the piston to be pulled up by the pump-rod P, which is heavy enough to serve as a counterpoise. C is the condenser, and A the air-pump, which discharges into the hot well H, whence the supply of the feed-pump F is drawn.

13. In a second patent (1781) Watt describes the “sun-and-planet” wheels and other methods of making the engine give continuous revolving motion to a shaft provided with a flywheel. He had invented the crank and connecting-rod for this purpose, but it had meanwhile been patented by one Pickard, and Watt, rather than make terms with Pickard, whom he regarded as a plagiarist of Rotative Engine. his own ideas, made use of his sun-and-planet motion until the patent on the crank expired. The reciprocating motion of earlier forms had served only for pumping; by this invention Watt opened up for the steam engine a thousand other channels of usefulness. The engine was still single-acting; the connecting-rod was attached to the far end of the beam, and that carried a counterpoise which served to raise the piston when steam was admitted below it.

Fig. 6.—Watt’s Single- Acting Engine, 1769.

14. In 1782 Watt patented two further improvements of the

first importance, both of which he had invented some years

before. One was the use of double action, that is

to say, the application of steam and vacuum to

each side of the piston alternately. The other

(invented as early as 1769) was the use of steam expansively,

Other Inventions

of Watt.

in other words the plan (now used in all engines that

aim at economy of fuel) of stopping the admission of steam

Fig. 7.—Watt’s Double-Acting

Engine, 1782.

when the piston had

made only a part of its

stroke, and allowing the

rest of the stroke to

be performed by the

expansion of the steam

already in the cylinder.

To let the piston push as

well as pull the end of the

beam Watt devised his

so-called parallel motion,

an arrangement of links

connecting the piston-rod

head with the beam

in such a way as to

guide the rod to move

in a very nearly straight

line. He further added

the throttle valve, for

regulating the rate of

admission of steam, and

the centrifugal governor,

a double conical pendulum,

which controlled

the speed by acting on

the throttle-valve. The stage of development reached at this

time is illustrated by the engine of fig. 7 (from Stuart’s

History of the Steam Engine), which shows the parallel

motion 𝑝𝑝, the governor 𝑔, the throttle-valve 𝑡, and a pair of

steam and exhaust valves at each end of the cylinder. Among

other inventions of Watt were the “indicator,” by which

diagrams showing the relation of the steam pressure in the

cylinder to the movement of the piston are automatically

drawn; a steam tilt-hammer; and also a steam locomotive

for ordinary roads—but this invention was not prosecuted.

In partnership with Matthew Boulton, Watt carried on in Birmingham the manufacture and sale of his engines with the utmost success, and held the field against all rivals in spite of severe assaults on the validity of his patents. Notwithstanding his accurate knowledge of the advantage to be gained by using steam expansively, he continued to employ only low pressures—seldom more than 7 ℔ per sq. in. over that of the atmosphere. His boilers were fed, as Newcomen’s had been, through an open pipe which rose high enough to let the column of water in it balance the pressure of the steam. He gave a definite numerical significance to the term “horse-power” (q.v.) as a mode of rating engines, defining it as the rate at which work is done when 33,000 ℔ are raised one foot in one minute.

15. In the fourth claim in Watt’s first patent the second

sentence describes a non-condensing engine, which would have

required steam of a higher pressure. This, however,

was a line of invention which Watt did not

follow up, perhaps because so early as 1725 a

non-condensing engine had been described by Jacob Leupold

Non-condensing Engine.

in his Theatrum machinarum. Leupold’s proposed engine

Fig. 8.—Leupold’s Non-Condensing Engine, 1725.

is shown in fig. 8, which

makes its action sufficiently

clear. Watt’s aversion to

high-pressure steam was

strong, and its influence on

steam engine practice long

survived the expiry of his

patents. So much indeed

was this the case that the

terms “high-pressure” and

“non-condensing” were for

many years synonymous in

contradistinction to the

“low-pressure” or condensing

engines of Watt. This

nomenclature no longer holds;

in modern practice many

condensing engines use as

high pressures as non-condensing

engines, and by doing

so are able to take advantage

of Watt’s great invention of expansive working to a degree

which was impossible in his own practice.

16. The introduction of the non-condensing and, at that time, relatively high-pressure engine was effected in England by Richard Trevithick and in America by Oliver Evans about 1800. Both Evans and Trevithick applied their engines to propel carriages on roads, and both used for boiler a cylindrical vessel with a cylindrical High-pressure Steam. flue inside—the construction now known as the Cornish boiler. In partnership with William Bull, Trevithick had previously made direct acting pumping-engines, with an inverted cylinder set over and in line with the pump-rod, thus dispensing with the beam that had been a feature in all earlier forms. But in these “Bull” engines, as they were called, a condenser was used, or, rather, the steam was condensed by a jet of cold water in the exhaust-pipe, and Boulton and Watt successfully opposed them as infringing Watt’s patents. To Trevithick belongs the distinguished honour of being the first to use a steam carriage on a railway; in 1804 he built a locomotive in the modern sense, to run on what had formerly been a horse-tramway, in Wales, and it is noteworthy that the exhaust steam was discharged into the funnel to force the furnace draught, a device which, twenty-five years later, in the hands of George Stephenson, went far to make the locomotive what it is to-day. In this connexion it may be added that as early as 1769 a steam carriage for roads had been built in France by Nicolas Joseph Cugnot, who used a pair of single-acting high-pressure cylinders to turn a driving axle step by step by means of pawls and ratchet-wheels. To the initiative of Evans may be ascribed the early general use of high-pressure steam in the United States, a feature which for many years distinguished American from English practice.

17. Amongst the contemporaries of Watt one name deserves special mention. In 1781 Jonathan Carter Hornblower constructed and patented what would now be called a compound engine, with two cylinders of different sizes. Steam was first admitted into the smaller cylinder, and then passed over into the larger, doing work Compound Engine. against a piston in each. In Hornblower’s engine the two cylinders were placed side by side, and both pistons worked on the same end of a beam overhead. This Was an instance of the use of steam expansively, and as such was earlier than the patent, though not earlier than the invention, of expansive working by Watt. Hornblower was crushed by the Birmingham firm for infringing their patent in the use of a separate condenser and air-pump. The compound engine was revived in 1804 by Arthur Woolf, with whose name it is often associated. Using steam of fairly high pressure, and cutting off the supply before the end of the stroke in the small cylinder, Woolf expanded the steam to several times its original volume. Mechanically the double-cylinder compound engine has this advantage over an engine in which the same amount of expansion is performed in a single cylinder, that the sum of the forces exerted by the two pistons in the compound engine Varies less throughout the action than the force exerted by the piston of the single-cylinder engine. This advantage may have been clear to Hornblower and Woolf and to other early users of compound expansion. But another and probably a more important merit of the system lies in a fact of which neither they nor for many years their followers in the use of compound engines were aware—the fact that by dividing the whole range of expansion into two parts the cylinders in which these are separately performed are subject to a reduced range of fluctuation in their temperature. This, as will be seen later, limits to a great extent a source of waste which is present in all steam engines, the waste which results from the heating and cooling of the metal by its alternate contact with hot and cooler steam. The system of compound expansion is now used in nearly all large engines that pretend to economy. Its introduction forms the most outstanding improvement which steam engines of the piston and cylinder type have undergone since the time of Watt; and we are able to recognize it as a very important step in the direction set forth in his “first principle” that the cylinder should be kept as hot as the steam that enters it.

18. Woolf introduced the compound engine somewhat widely about 1814 as a pumping engine in the mines of Cornwall. But here it met a strong competitor in the high-pressure single-cylinder engine of Trevithick, which had the advantage of greater simplicity in construction. Woolf’s engine fell into comparative disuse, and the Cornish Engine. single-cylinder type took a form which, under the name of the Cornish pumping engine, was for many years famous for its great economy of fuel. In this engine the cylinder was set under one end of a beam, from the other end of which hung a heavy rod which operated a pump at the foot of the shaft. Steam was admitted above the piston for a short portion of the stroke, thereby raising the pump-rod, and was allowed to expand for the remainder. Then an equilibrium valve, connecting the space above and below the piston, as in fig. 6, was opened, and the pump-rod descended, doing work in the pump and raising the engine piston. The large mass which had to be started and stopped at each stroke served by its inertia to counterbalance the unequal pressure of the steam, for the ascending rods stored up energy of motion in the early part of the stroke, when the steam pressure was greatest, and gave out energy in the later part, when expansion had greatly lowered the pressure. The frequency of the stroke was controlled by a device called a cataract, consisting of a small plunger pump, in which the plunger, raised at each stroke by the engine, was allowed to descend more or less slowly by the escape of fluid below it through an adjustable orifice, and in its descent liberated catches which held the steam and exhaust valves from opening. A similar device controlled the equilibrium valve, and could be set to give a pause at the end of the piston’s down-stroke, so that the pump-cylinder might have time to become completely filled. The Cornish engine is interesting as the earliest form which achieved an efficiency comparable with that of good modern engines. For many years monthly reports were published of the “duty” of these engines, the “duty” being the number of foot-pounds of work done per bushel or (in some cases) per cwt. of coal. The average duty of engines in the Cornwall district rose from about 18 millions of foot-pounds per cwt. of coal in 1813 to 68 millions in 1844; after which less effort seems to have been made to maintain a high efficiency (Proc. Inst. C.E., 1863, vol. 23). In individual cases much higher results were reported, as in the Fowey Consols engine, which in 1835 was stated to have a duty of 125 millions. This (to use a more modern mode of reckoning) is equivalent to the consumption of only a little more than 1+3/4 ℔ of coal per horse-power per hour—a result surpassed by very few engines in even the best recent practice. It is difficult to credit figures which, even in exceptional instances, place the Cornish engine of that period on a level with the most efficient modern engines—in which compound expansion and higher pressure combine to make a much more perfect thermodynamic machine; and apart from this there is room to question the accuracy of the Cornish reports. They played, however, a useful part in the process of steam engine development by directing attention to the question of efficiency, and by demonstrating the advantage to be gained by high pressure and expansive working, at a time when the theory of the steam engine had not yet taken shape.

19. The final revival of the compound engine did not occur until about the middle of the 19th century, and then several agencies combined to effect it. In 1845 M‘Naught introduced a plan of improving beam engines of the original Watt type, by adding a high-pressure cylinder whose piston acted on the beam between the centre Compound Engine. and the flywheel end. Steam of higher pressure than had formerly been used, after doing work in the new cylinder, passed into the old or low-pressure cylinder, where it was further expanded. Many engines whose power was proving insufficient for the extended machinery they had to drive were “M‘Naughted” in this way, and after conversion were found not only to yield more power but to show a marked economy of fuel. The compound form was selected by William Pole for the pumping engines of Lambeth and other waterworks about 1850; in 1854 John Elder began to use it in marine engines; in 1857 E. A. Cowper added a steam-jacketed intermediate reservoir for steam between the high and low pressure Cylinders, which made it unnecessary for the low-pressure piston to be just beginning when the other piston was just ending its stroke. As facilities increased for the use of high-pressure steam, compound expansion came into more, general use, its advantage becoming more conspicuous with every increase in boiler pressure—until now there are few large land engines and scarcely any marine engines that do not employ it. In marine practice, where economy of fuel is a much more important factor in determining the design than it is on land, the principle of compound expansion has been greatly extended by the introduction of triple and even quadruple expansion engines, in which the steam is made to expand successively in three or in four cylinders. In locomotive engines, where other considerations are of more moment than the saving of coal, compound expansion has found some application, but its use there is comparatively rare.

20. The adaptation of the steam engine to railways, begun by Trevithick, became a success in the hands of George Stephenson, whose engine, the “Rocket,” when tried along with others, in 1829, not only distanced its competitors but settled once and for all the question whether horse traction or steam traction was to be used Application to Locomotives. on railways. The principal features of the “Rocket” were an improved steam-blast for urging "the combustion of coal and a boiler (suggested by Booth) in which a large heating surface was given by the use of many small tubes through which the hot gases passed. Further, the cylinders, instead of being vertical as in earlier locomotives, were set in at a slope, which was afterwards altered to a position more nearly horizontal. To these features there was added later the “link motion,” a contrivance which enabled the engine to be easily reversed and the amount of expansion to be readily varied. In the hands of George Stephenson and his son Robert the locomotive took a form which has been in all essentials maintained by the far heavier locomotives of to-day.

21. The first practical steamboat was the tug “Charlotte Dundas,” built by William Symington, and tried in the Forth and Clyde Canal in 1802. A Watt double-acting condensing engine, placed horizontally, acted directly a connecting-rod on the crank of a shaft at the stern, which carried a revolving paddle-wheel. The trial Application to Steamboats. was successful, but steam towing was abandoned for fear of injuring the banks of the canal. Ten years later Henry Bell built the “Comet,” with side paddle-wheels, which ran as a passenger steamer on the Clyde; but an earlier inventor to follow up Symington’s success was the American, Robert Fulton, who, after unsuccessful experiments on the Seine, fitted a steamer on the Hudson in 1807 with engines made to his designs by Boulton and Watt, and brought steam navigation for the first time to commercial success.

22. With improvements in the details of design and construction it gradually became practicable to use higher steam pressures and higher piston speeds, and consequently to obtain not only greater efficiency, but also a greater amount of power from engines of given bulk. In 1872 Sir F. J. Bramwell, describing the typical Rise in Steam Pressure and in Piston Speed. marine practice of that time, gave a list of engines, all compound, in which the boiler pressure ranged from 45 to 60 ℔, the mean piston speed was 350 ft. per minute, and the consumption of coal 2 to 2+1/2 ℔ per hour per indicated horse-power. In 1881 F. C. Marshall gave a similar list, in which the boiler pressure was 77 ℔, the speed 460 ft. per minute, and the consumption a trifle under 2 ℔. These were compound engines with expansion in two stages. The triple expansion engine, introduced by Dr A. C. Kirk in 1874, did not come into general use until after 1881. It became the normal type of marine engine, with pressures ranging, as a rule, from 150 to 200 ℔, piston speeds generally of 500 or 600 ft. per minute, but sometimes as high as 900 or 1000, and coal consumption of about 1+1/2 ℔ per hour per indicated horse-power. In some Triple and Quadruple Expansion. instances quadruple expansion has been preferred, with somewhat higher pressures, but it can scarcely be said to be established that the advantage of adding a fourth stage clearly compensates for the extra complication. Some particulars of the dimensions reached in modern practice will be given later. Several of the vessels engaged in the Transatlantic passenger service, and also a few armoured cruisers, have engines in which the twin sets together have an indicated horse-power exceeding 30,000. But even these figures are eclipsed in ships which are driven by turbine engines. The cruisers of the “Invincible” class have turbine engines of 41,000 horse-power, and the turbines of the great Cunarders “Lusitania” and “Mauretania” (1907) develop about 70,000 h.p. in propelling these ships at a speed of 25 knots. It may be questioned whether such gigantic concentrations of power for the propulsion of a ship would have been practicable had it not been for the new possibilities which the introduction of the steam turbine has opened up.

23. The invention of the steam turbine has in fact revolutionized marine engine practice, so far as fast vessels are concerned, and has supplied a formidable rival to the reciprocating engine for use on land. The steam turbine has been brought to a degree of efficiency which places it, in respect of economy in steam Introduction of the Steam Turbine. than the best engines of the older type in cases where a large amount of power is to be generated. Its greater simplicity, compactness and freedom from vibration are merits which have already gone far to secure for it a preference, notwithstanding the short time that has passed since it became known as a practicable engine. The largest demands for power occur in fast passenger vessels, in war-ships and in stations from which electric energy is distributed for traction or other uses; in all these cases the steam turbine is now taking the leading place. It is to the inventive genius of the Hon. C. A. Parsons that we owe not only the main idea of the modern steam turbine, but also the working out of many novel mechanical details which have been essential to success, as well as the adaptation of the turbine to marine propulsion.

24. In the steam turbine, as in the water turbine (for which see Hydraulics), the force directly operative to do useful work is derived from the kinetic energy of the operative fluid, either by the impulse of a jet or jets sliding over movable blades, or by the reaction of orifices or guides from which the jets issue. The pressure, instead of being exerted on a piston, is employed in the first instance to set the fluid itself in motion. There is a conversion of pressure-energy into velocity-energy as a preliminary step towards obtaining the effective work of the machine. But in a steam turbine this implies velocities which are immensely greater than those with which water turbines have to deal, in consequence of the much smaller density of steam as the moving fluid. Attempts to design a steam turbine were made by numerous inventors, but fell short of practical success mainly because of the difficulty of arranging for a sufficiently high velocity in the working parts to utilize a reasonably large fraction of the kinetic energy of the steam, the principle involved being that for good efficiency the velocity of the blades should approximate to half the velocity of the jets which strike them. There is a further difficulty in getting the energy of the steam into a suitable kinetic form, namely, to get the stream of issuing particles to take a single direction, without undue dispersion, when steam is allowed to expand through an orifice from a chamber at high pressure into a space where the pressure is greatly less.

In 1889 Dr Gustaf de Laval introduced a form of steam turbine in which both of these difficulties were to a great extent overcome, partly by the special form of the nozzle used to produce the steam jet and partly by features of design which allowed an exceptionally high speed to be reached in the wheel carrying the vanes against which the steam impinged. This simple type of turbine, which will be described in a later section of this article, has met with considerable success, especially in comparatively small sizes, as an engine for driving electric generators. Its efficiency is fairly good, but it is not well adapted for work on a large scale, and it has not been applied to the propulsion of ships.

Parsons attacked the problem at an earlier date, in an entirely different way in the invention of his “compound” turbine. By dividing the whole expansion of the steam into a great number of successive and separate steps he limited the velocity acquired at each step to such an extent as to make it comparatively easy to extract the greater part of the kinetic energy, as work done upon the moving blades, without making the velocity of these blades inconveniently high. Moreover, in Parsons’s compound turbine the range of pressure through which the steam expands in each separate step is too small to give rise to any difficulty in the formation of the jets. The guide blades, which form the jets, are distributed round the whole circumference of the revolving wheel, and all the revolving blades are consequently in action at once. The steam streams from end to end through an annular space between a revolving drum and the casing which surrounds it. Parallel rings of fixed guide blades project inwards from the casing at suitable distances, and between these are rings of moving blades which project outwards from the drum and revolve with it. At each step in the expansion the steam streams through a ring of fixed guide blades, and the streams so formed impinge on the next ring of moving blades, and so on. The construction, which is of great simplicity, will be described later; it lends itself well to the generation of power on a large scale, especially in cases where a fairly high speed of rotation is wanted. The more powerful the turbine the less important do various inevitable sources of loss become; and hence, though the small turbines which were first built were less economical than reciprocating engines, the advantage is the other way where large powers are concerned.

25. Parsons introduced his compound steam turbine in 1884. For some years it was made in small sizes only, and the steam was discharged to the atmosphere without condensation. So long, however, as this was done the steam turbine was sacrificing one of its most important advantages, namely, its exceptional capacity for utilizing the energy of low-pressure steam down to the lowest vacuum obtainable in a condenser. In 1891 it was first fitted with a condenser, and it then began to be used in electric supply stations. Its efficiency at that date was found, in tests made by the present writer, to be comparable with that of good reciprocating compound engines, but the figures then obtained were much improved on later in turbines of larger size and modified design. The first application to marine propulsion was in the “Turbinia,” in 1897. The success of this little experimental vessel of 100 tons, which with its horse-power of 2100 made a record in speed for a ship of any size, was soon followed by the application of the turbine to various war-ships and other steamers. In war-ships the use of steam turbines has a special advantage in enabling the machinery to be kept at a low level, beneath the protective deck, in addition to the general advantages of reduced bulk, reduced vibration, reduced liability to break-down, and reduced consumption of coal and of oil which are common to vessels of all classes. The successful trials of the cruiser “Amethyst” in 1904 demonstrated these advantages so conclusively that all new war-ships for the British navy, from battleships to torpedo-boats are being fitted with steam turbines. It is also used in many cross-channel packets, as well as in the largest ocean-going passenger vessels. The turbine-driven steamers “Lusitania” and “Mauretania” (1907) are the most powerful and the fastest ocean-going vessels afloat. The rapid development of the marine steam turbine makes it probable that it will displace the reciprocating engine in all large and fast ships. For slow-going cargo-boats it is at a disadvantage, unless gearing is resorted to, on account of the difficulty of securing a sufficiently high peripheral velocity in the turbine drums without making the turbines unduly bulky, and the leakage losses (due to steam passing through the clearance spaces over the tips of the blades) unduly large. Experiments by Parsons (Trans. Inst. Nav. Arch., 1910) on a ship in which a slow-running propeller is driven through reducing-gear from a high-speed turbine, have given highly promising results.

Enough has been said to show that the invention of the steam turbine is the most important step in steam engineering since the time of Watt. It is the first solution of the problem of using steam efficiently in an engine without reciprocating parts. The object in most steam engines is to deliver power to revolving machinery, and much ingenuity has been expended in attempts to devise engines which will produce rotation directly, instead of by conversion of reciprocating motion. No rotary engine, however, was permanently successful until the steam turbine took a practical form.

26. In the early development of the steam engine inventors had little in the way of theory to guide them. Watt had the advantage, which he acknowledges, of a knowledge of Joseph Black’s doctrine of latent heat; but there was no philosophy of the relation of work to heat until long after the inventions of Watt were complete. The theory of the steam engine as a heat engine dates from 1824, when N. L. Sadi Carnot published his Réflexions sur Theory of Steam Engine. la puissance motrice du feu, and showed that heat does work only by being let down from a higher to a lower temperature. But Carnot had no idea that any of the heat disappears in the process, and it was not until the doctrine of the conservation of energy was established in 1843 by the experiments of J. P. Joule that the theory of heat engines began a vigorous growth. From 1849 onwards the science of thermodynamics was developed with extraordinary rapidity by R. J. M. Clausius, W. J. Macquorn Rankine and William Thomson (Lord Kelvin) and was applied, especially by Rankine, to practical problems in the use of steam. The publication in 1859 of Rankine’s Manual of the Steam Engine formed an epoch in the history of the subject by giving inventors a new basis, outside of mere empiricism, from which they could push on the development of the steam engine. Unfortunately, however, it was assumed that the cylinder and piston might be treated as behaving to the steam like non-conducting bodies—that the transfer of heat between the steam and the metal was negligibly small. Rankine’s calculations of steam consumption, work and thermodynamic efficiency involve this assumption, except in the case of steam-jacketed cylinders, where he estimates that the steam in its passage through the cylinder takes just enough heat from the jacket to prevent a small amount of condensation which would otherwise occur as the process of expansion goes on. If the transfer of heat from steam to metal could be overlooked, the steam which enters the cylinder would remain during admission as dry as it was before it entered, and the volume of steam consumed per stroke would correspond with the volume of the cylinder up to the point of cut-off. It is here that the actual behaviour of steam in the cylinder diverges most widely from the behaviour which the theory assumes. When steam enters the cylinder it finds the metal chilled by the previous exhaust, and a portion of it is at once condensed. This has the effect of increasing, often very largely, the volume of boiler steam required per stroke. As expansion goes on the water that was condensed during admission begins to be re-evaporated from the sides of the cylinder, and this action is often prolonged into the exhaust. It is now recognized that any theory which fails to take account of these exchanges of heat between the steam and its metal envelope fails also to yield even comparatively correct results in calculating the relative efficiency of various steam pressures or various ranges of expansion. But the exchanges of heat are so complex that there seems little prospect of submitting them to any comprehensive theoretical treatment, and information is rather to be sought from the scientific analysis of experiments with actual machines.

27. Formation of Steam under Constant Pressure.—In attempting a brief sketch of steam engine theory it is necessary to begin by giving some account of the properties of steam, so far as they are relevant. The properties of steam are most conveniently stated by referring in the first instance to what happens when steam is formed under constant pressure. This is substantially the process which occurs in the boiler of a steam engine when the engine is at work. To fix the ideas we may suppose that the vessel in which steam is to be formed is a long upright cylinder fitted with a piston which may be loaded so that it exerts a constant pressure on the fluid below. Let there be, to begin with, at the foot of the cylinder a quantity of water (which for convenience of numerical statement we shall take as 1 ℔), at any temperature 𝑡0; and let the piston press on the surface of the water with a force of 𝑝 ℔ per square foot. Let heat now be applied to the bottom of the cylinder. As it enters the water it will produce the following effects in three stages:—

1. The temperature of the water rises until a certain temperature 𝑡 is reached, at which steam begins to be formed. The value of 𝑡 depends on the particular pressure 𝑝 which the piston exerts. Until the temperature 𝑡 is reached there is nothing but water below the piston.

2. Steam is formed, more heat being taken in. The piston (which is supposed to exert a constant pressure) rises. No further increase of temperature occurs during this stage, which continues until all the water is converted into steam. During this stage the steam which is formed is said to be saturated. The volume which the piston encloses at the end of this stage—the volume, namely, of 1 ℔ of saturated steam at pressure 𝑝 (and temperature 𝑡)—will be denoted by 𝑣 in cubic feet.

3. If after all the water is converted into steam more heat be allowed to enter, the volume will increase and the temperature will rise. The steam is then said to be superheated.

The difference between saturated and superheated steam may be expressed by saying that if water (at the temperature of the steam) be mixed with steam some of the water will be evaporated if the steam is superheated, but none if the steam is saturated. Any vapour in contact with its liquid and in thermal equilibrium is necessarily saturated. When saturated its properties differ considerably, as a rule, from those of a perfect gas, especially at high pressures, but when superheated they approach those of a perfect gas more and more closely the further the process of superheating is carried, that is to say, the more the temperature is raised above 𝑡, the temperature of saturation corresponding to the given pressure 𝑝.

28. Relation of Pressure and Temperature in Saturated Steam.—The temperature 𝑡 at which steam is formed depends on the value of 𝑝. Their relation was determined with great care by Regnault (Mem. Inst. France, vol. xxi.). The pressure of saturated steam rises with the temperature at a rate which increases rapidly in the upper regions of the scale. This will be apparent from the first and second columns of the following table. The first column gives the temperature on the Centigrade scale; the second gives the corresponding pressure in pounds per square inch.

29. Relation of Volume and Temperature.—The same table shows the volume 𝑣 in cubic feet occupied by 1 ℔ of saturated steam at each temperature. This is based on the investigations of H. L. Callendar who has shown (see Thermodynamics and Vaporization) that an equation of the form

𝑣=Rτ/𝑝 + 𝑏 − 𝑐

is applicable to water vapour, whether saturated or superheated, within the limits of experimental error throughout the range of pressure that is important in engineering practice. In this equation τ is the absolute temperature, R and 𝑏 are constants and 𝑐 is a term varying inversely as a certain power of the temperature. By aid of this equation, in conjunction with the results of various experiments on the latent heat and other properties of steam, Callendar has shown that it is possible to frame expressions from which numerical values of all the important properties of steam may be derived throughout a range of saturation temperatures extending from 0° C. to 200° C. or so. The values so obtained are thermodynamically consistent with one another, and are in good agreement with the most authoritative experimental results. They are accordingly to be accepted in lieu of those given in earlier steam tables which depended on measurements by Regnault, and are now known to be in some particulars erroneous. R. Mollier has applied Callendar’s method with great completeness to the calculation of steam tables, and the figures given here are adapted from his results.[5] In addition to the relation of temperature, pressure and volume, the table shows other properties of steam which will be explained as we proceed.

30. Supply of Heat in Formation of Steam under Constant Pressure.—We have next to consider the supply of heat in the imaginary experiment of § 27. During the first stage, until the temperature rises from its initial value 𝑡0 to 𝑡, the temperature at which steam begins to form under the given pressure, heat is required only to warm the water. Since the specific heat of water is nearly constant, the amount of heat taken in during the first stage is approximately 𝑡—𝑡0 thermal units, or J (𝑡—𝑡0) foot-pounds, J being Joule’s equivalent, and this expression for it will generally serve with sufficient accuracy in practical calculations. More exactly, however, the heat taken in is somewhat greater than this at high temperatures, for Regnault’s experiments show that the specific heat of water increases slightly as the temperature rises. In stating the amount of heat required for this first stage, to must be taken as a known temperature; for convenience in numerical statement the temperature 0° C. is usually chosen as an arbitrary starting-point from which the reception of heat is to be reckoned. We shall employ the symbol ℎ to designate the heat required to raise 1 ℔ of water from 0° C. to the temperature 𝑡 at which steam begins to form. During the first stage, sensibly all the heat supplied goes to increase the stock of internal energy which the fluid possesses, the amount of external work which is done by the expansion of the fluid being negligible.

The heat taken in during the second stage is what is called the latent heat of steam, and is denoted by L. Of it a part is spent in doing external work, namely, 𝑝 multiplied by the excess of the volume of the steam 𝑣 over the volume of the water 𝑤, and the remainder is the difference of internal energy between 1 ℔ of steam at 𝑡 and 1 ℔ of water at 𝑡.

31. Total Heat of Steam.—Adding together the heat taken in during the first and second stages, we have a quantity designated by H which may be called the heat of formation of 1 ℔ of saturated steam:—

H=ℎ+L.

The heat of formation of 1 ℔ of steam, when formed under constant pressure from water at any temperature to, is H−ℎ0, where ℎ0 corresponds to 𝑡0.

It has been pointed out by Mollier that for the purpose of calculations in technical thermodynamics it is convenient to add to the heat of formation the quantity 𝑝𝑤/J, which represents the thermal equivalent of the work spent in introducing the water under the piston, against the constant pressure 𝑝, before the operation of heating imagined in § 27 begins, 𝑤 being the volume of the water. We thus obtain a quantity which in its numerical values differs only very slightly from H, namely

I=H+𝑝𝑤/J.

We shall call this the total heat of saturated steam. Values of I are stated in the table. Since the volume of 1 ℔ of water is only 0·016 cub. ft. the term 𝑝𝑤/J is numerically insignificant except at the highest pressures. Similarly, in reckoning the total heat of water I𝑤 we add 𝑝𝑤/J to ℎ, and this quantity is also given in the table. The latent heat L is to be found from the table by subtracting I𝑤, the total heat of water, from the total heat of steam. We shall use the centigrade scale of temperature throughout this article, and accordingly the total heats are expressed in terms of a unit involving the centigrade degree, namely, the quantity of heat required to raise the temperature of unit mass of water through 1° C. at 15° C. With this unit of heat the mechanical equivalent J is 1400 foot-pounds when the unit of mass is the ℔, and is 427 kilogram-metres when the unit of mass is the kilogramme.

| Tempera- ture. Centigrade. |

Pressure ℔ per sq. in. |

Volume cub. ft. per ℔. |

Total Heat. | Entropy. | ||

| Of Water. | Of Steam. | Of Water. | Of Steam. | |||

| 0 | 0·089 | 3283. | 0 | 594·7 | 0 | 2·178 |

| 5 | 0·127 | 2354. | 5·0 | 597·1 | 0·018 | 2·148 |

| 10 | 0·178 | 1708. | 10·0 | 599·4 | 0·036 | 2·119 |

| 15 | 0·246 | 1253. | 15·0 | 601·8 | 0·054 | 2·091 |

| 20 | 0·336 | 931. | 20·0 | 604·1 | 0·071 | 2·064 |

| 25 | 0·455 | 699·5 | 25·0 | 606·5 | 0·088 | 2·039 |

| 30 | 0·610 | 530·7 | 30·0 | 608·8 | 0·104 | 2·015 |

| 35 | 0·809 | 406·8 | 35·0 | 611·1 | 0·121 | 1·991 |

| 40 | 1·062 | 314·8 | 40·1 | 613·5 | 0·137 | 1·969 |

| 45 | 1·381 | 245·8 | 45·1 | 615·8 | 0·153 | 1·947 |

| 50 | 1·78 | 193·7 | 50·1 | 618·0 | 0·169 | 1·927 |

| 55 | 2·27 | 153·9 | 55·1 | 620·3 | 0·184 | 1·907 |

| 60 | 2·88 | 123·3 | 60 1 | 622·6 | 0·199 | 1·888 |

| 65 | 3·61 | 99·5 | 65·2 | 624·8 | 0·214 | 1·870 |

| 70 | 4·51 | 80·9 | 70·2 | 627·0 | 0·229 | 1·852 |

| 75 | 5·58 | 66·24 | 75·3 | 629·2 | 0·244 | 1·835 |

| 80 | 6·86 | 54·60 | 80·3 | 631·3 | 0·258 | 1·819 |

| 85 | 8·38 | 45·29 | 85·3 | 633·5 | 0·272 | 1·803 |

| 90 | 10·16 | 37·79 | 90·4 | 635·6 | 0·286 | 1·788 |

| 95 | 12·26 | 31·71 | 95·5 | 637·6 | 0·300 | 1·773 |

| 100 | 14·70 | 26·75 | 100·5 | 639·7 | 0·314 | 1·759 |

| 105 | 17·52 | 22·69 | 105·6 | 641·7 | 0·327 | 1·745 |

| 110 | 20·79 | 19·34 | 110·7 | 643·6 | 0·340 | 1·732 |

| 115 | 24·55 | 16·56 | 115·8 | 645·5 | 0·354 | 1·719 |

| 120 | 28·83 | 14·25 | 120·9 | 647·4 | 0·367 | 1·706 |

| 125 | 33·72 | 12·30 | 126·0 | 649·2 | 0·379 | 1·694 |

| 130 | 39·26 | 10·67 | 131·1 | 651·0 | 0·392 | 1·682 |

| 135 | 45·51 | 9·29 | 136·2 | 652·8 | 0·405 | 1·671 |

| 140 | 52·56 | 8·12 | 141·3 | 654·5 | 0·417 | 1·660 |

| 145 | 60·42 | 7·13 | 146·4 | 656·1 | 0·430 | 1·649 |

| 150 | 69·24 | 6·274 | 151·6 | 657·8 | 0·442 | 1·638 |

| 155 | 79·04 | 5·542 | 156·7 | 659·3 | 0·454 | 1·628 |

| 160 | 89·93 | 4·910 | 161·9 | 660·8 | 0·466 | 1·618 |

| 165 | 101·98 | 4·363 | 167·1 | 662·3 | 0·478 | 1·608 |

| 170 | 115·27 | 3·891 | 172·2 | 663·7 | 0·489 | 1·599 |

| 175 | 129·9 | 3·478 | 177·4 | 665·0 | 0·501 | 1·589 |

| 180 | 145·9 | 3·116 | 182·6 | 666·3 | 0·512 | 1·580 |

| 185 | 163·4 | 2·800 | 187·9 | 667·6 | 0·524 | 1·571 |

| 190 | 182·6 | 2·523 | 193·1 | 668·8 | 0·535 | 1·563 |

| 195 | 203·4 | 2·279 | 198·3 | 670·0 | 0·546 | 1·554 |

| 200 | 226·0 | 2·063 | 203·6 | 671·1 | 0·557 | 1·546 |

| 205 | 250·5 | 1·874 | 208·9 | 672·2 | 0·568 | 1·538 |

| 210 | 277·2 | 1·703 | 214·1 | 673·2 | 0·579 | 1·530 |

| 215 | 306·8 | 1·546 | 219·4 | 674·1 | 0·590 | 1·522 |

32. Internal Energy.—Of the heat of steam the part 𝑝𝑣/J is spent in doing external work. The remainder has gone to increase the stock of internal energy which the substance possesses.

In dealing with the heat required to produce steam we adopted the state of water at 0°C. as an arbitrary starting-point from which to reckon the reception of heat. In the same way it is convenient to use this arbitrary starting-point in reckoning what may be called the internal energy of the substance, which is the excess of the heat taken in over the external work done by the substance during its reception of heat. Thus the internal energy E of 1 ℔ of saturated steam at pressure 𝑝 is equal to the total heat I, less that part of the total heat which is spent in doing external work, or

E=I−𝑝𝑣/J.

The notion of internal energy is useful in calculating the heat taken in or rejected by steam during any stage of its expansion or compression in an engine. When a working substance passes from one condition to another its gain or loss of heat is determined by the equation

Heat taken in=increase of internal energy+external work.

Any of the terms of this equation may be negative; the last term is negative when work is done, not by but upon the substance.

33. Wet Steam.—In calculations which relate to the action of steam in engines we have often to deal, not with dry saturated steam, but with wet steam, or steam which either carries in suspension, or is otherwise mixed with, a greater or less proportion of water. In any such mixture, assuming it to be in equilibrium, the steam and water have the same temperature, and the steam is saturated. The dryness of wet steam is measured by the proportion 𝑞 of dry steam in each pound of the mixed substance. When that is known it is easy to determine the other physical constants: thus—

| Latent heat of 1 ℔ of wet steam | =𝑞L; |

| Total heat of 1 ℔ of wet steam | =I𝑤+𝑞L; |

| Volume of 1 ℔ of wet steam | =𝑞𝑣+(1−𝑞)𝑤 |

| =𝑞𝑣 very nearly, |

unless the steam is so wet as to consist mainly of water.

34. Superheated Steam.—Steam is superheated when its temperature is raised, in any manner, above the temperature corresponding to saturation at the actual pressure. When considerably superheated, steam approximates in behaviour to a perfect gas.

The specific heat during superheating is nearly constant at low pressures, its value being approximately 0·48; at high pressures it is higher, especially when the amount of superheating is slight. Callendar’s equations enable it to be calculated for any assigned conditions of temperature and pressure. They also allow a direct determination to be made of the total heat of superheated steam of given temperature and pressure, and from this, by comparison with the total heat of saturated steam at the same pressure, the mean specific heat over any stated range of superheating, may be found. Calling I𝑠, the total heat of steam in the saturated condition, when the temperature is 𝑡, κ the mean specific heat in superheating at constant pressure to a higher temperature 𝑡′ and I′ the total heat in the superheated state, we have

I′=I𝑠, +κ(𝑡′−𝑡).

The following are values of κ:—

| Temperature of Superheat 𝑡′ in °C. |

Temperature of Saturation 𝑡 in °C. | ||||

| 80° | 120° | 160° | 180° | 200° | |

| 100° | 0·49 | ||||

| 150° | 0·49 | 0·51 | |||

| 200° | 0·49 | 0·51 | 0·54 | 0·57 | |

| 250° | 0·48 | 0·50 | 0·53 | 0·56 | 0·59 |

| 300° | 0·48 | 0·50 | 0·52 | 0·54 | 0·57 |

| 350° | 0·48 | 0·49 | 0·51 | 0·53 | 0·56 |

| 400° | 0·48 | 0·49 | 0·51 | 0·52 | 0·55 |

| 450° | 0·48 | 0·49 | 0·51 | 0·52 | 0·54 |

35. Isothermal Expansion of Steam.—The expansion of volume which occurs during the conversion of water into steam under constant pressure is isothermal. From what has been already said it is obvious that steam, or any other saturated vapour, can be expanded or compressed isothermally only when wet, and that evaporation (in the one case) or condensation (in the other) must accompany the process. Isothermal lines for a working substance which consists of a liquid and its vapour are straight lines of uniform pressure.

36. Adiabatic Expansion of Steam.—If steam initially dry be allowed to expand adiabatically (namely, without taking in or giving out any heat) it becomes wet. A part of the steam is condensed by the process of adiabatic expansion, at first in the form of minute particles suspended throughout the mass. The temperature and pressure fall; and, as that part of the substance which remains uncondensed is saturated, the relation of pressure to temperature throughout the expansion is that which holds for saturated steam. Before expansion let the initial dryness of the steam be 𝑞1 and its absolute temperature τ. Then, if it expand adiabatically until its temperature falls to τ, its dryness after expansion may be shown to be

𝑞=τ/L (𝑞1L1/τ1 + logετ1/τ).

L1, and L are the latent heats (in thermal units) of 1 ℔ of steam before and after expansion respectively. When the steam is dry to begin with, 𝑞1=1.

This formula is easily applied to the construction of the adiabatic curve when the initial pressure and the pressure after expansion are given, the corresponding values τ and L being found from the table.

37. Ideal Action of Heat Engine.—According to the principles of thermodynamics (q.v.), the action of a heat engine depends on its receiving heat at a temperature higher than that at which it is capable of rejecting heat to surrounding objects. The working substance in the engine must necessarily pass from an upper temperature, at which it takes in heat, to a lower temperature, at which it rejects heat, the difference, between the heat taken in and the heat rejected being the thermal equivalent of the work done. It may readily be shown that when the conditions are such as to make this difference as great as possible—in other words, to make the efficiency reach its ideal limit—the ratio of the heat taken in to the heat rejected depends only on the temperature at which reception and rejection of heat occur. Calling τ1 and τ2 the absolute temperatures at which heat is taken in and rejected respectively, and Q1 and Q2 the quantities of heat taken in and rejected, the limit of efficiency is reached when Q1/Q2=τ1/τ2. The efficiency then has the value

(Q1−Q2)/Q1=(τ1 − τ2)/τ1

and W, the work done, is Q1(τ1 − τ2)/τ1.

In the ideal engine imagined by Carnot the action is of this simple character. The working substance is brought by adiabatic compression from the lower to the upper extreme of temperature. It then takes in heat, without changing in temperature. Next, it expands adiabatically until its temperature falls to the lower extreme and finally at that temperature it rejects enough heat to restore it to its initial state, thereby completing a cycle of operations.

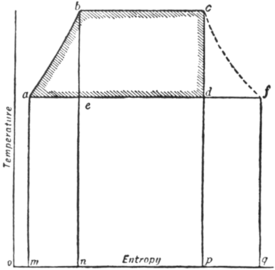

38. Carnot’s Cycle with Steam for Working Substance.—We are now in a position to study the action of a heat engine employing steam as the working substance. To simplify the first consideration as far as possible, let it be supposed that we have a long cylinder composed of non-conducting material except at the base, and fitted with a non-conducting piston; also a source of heat A at some temperature τ1; a receiver of heat, or, as we may now call it, a condenser C, at a lower temperature τ2; and a non-conducting cover B. Then We can perform as follows the ideal reversible cycle of operations first described by Carnot, which gives the highest possible efficiency attainable in any heat engine. To fix the ideas, suppose that there is 1 ℔ of water in the cylinder to begin with, at the temperature τ1:—

| |

| Fig. 9.—Carnot’s Cycle with water and steam for working substance. | |

1. Apply A, and allow the piston to rise. The water will take in heat and be converted into steam, expanding isothermally at constant pressure 𝑝1. This part of the operation is shown by the line 𝑎𝑏 in fig. 9.

2. Remove A and apply B. Allow the expansion to continue adiabatically (𝑏𝑐), with falling pressure, until the temperature falls to τ2. The pressure will then be 𝑝2, namely, the pressure given in the table corresponding to τ2.

3. Remove B, apply C, and compress. Steam is condensed by rejecting heat to C. The action is isothermal, and the pressure remains 𝑝2. Let this be continued until a certain point 𝑑 is reached, after which adiabatic compression will complete the cycle.

4. Remove C and apply B. Continue the compression, which is now adiabatic. If the point 𝑑 has been rightly chosen, this will complete the cycle by restoring,the working fluid to the state of water at temperature τ1.

The “indicator diagram” or diagram exhibiting the relation of pressure to volume for such a cycle is given in fig. 9. Since the process is reversible, and since heat is taken in only at τ1 and rejected only at τ2, the ideal conditions for perfect efficiency are satisfied, and accordingly the efficiency is (τ1−τ2)/τ1. The heat taken in per ℔ of the fluid is L1, and the work done is L1(τ1−τ2)/τ1, a result which may be used to check the calculation of the diagram.

39. Efficiency of a Perfect Steam Engine: Limits of Temperature.— If the action here described could be realized in practice, we should have a thermodynamically perfect steam engine using saturated steam. The fraction of the heat supplied to it which such an engine would convert into work would depend simply on the temperature, and therefore on the pressure, at which the steam was produced and condensed. The temperature of condensation is limited by the consideration that there must be an abundant supply of some substance to absorb the rejected heat; water is actually used for this purpose, so that τ2 has for its lower limit the temperature of the available water-supply.

To the higher temperature τ1 a practical limit is set by the mechanical difficulties, with regard to strength and to lubrication, which attend the use of high-pressure steam. In engines of ordinary construction the pressure is rarely so much as 250 ℔ per sq. in.

It must not be supposed that the efficiency (τ1−τ2)/τ1 is actually attained, or is even attainable. Many causes conspire to prevent steam engines from being thermodynamically perfect, and some of the causes of imperfection cannot be removed.

40. Engine with Separate Organs.—In the ideal engine represented in fig. 10 the functions of boiler, cylinder and condenser are combined in a single vessel; but, provided the working substance passes through the same cycle of operations, it is indifferent whether these are performed in several vessels or in one. To approach a little more closely the conditions that hold in practice, we may think of the engine as consisting of a boiler A (fig. 10) kept at τ1, a non-conducting cylinder and piston B, a surface condenser C kept at τ2, and a feed-pump D which restores the condensed water to the boiler. When the several organs of the engine are separated in this way we can still carry out the first three stages of the cyclic process described in § 38. The first stage of that cycle corresponds to the admission of steam from the boiler into the cylinder. Then the point known as the point of cut-off is reached, at which admission ceases, and the steam already in the cylinder is allowed to expand, exerting a diminishing pressure on the piston. This is the second stage, or the stage of expansion. The process of expansion may be carried on until the pressure falls to that of the condenser, in which case the expansion is said to be complete. At the end of the expansion release takes place, that is to say, communication is opened with the condenser. Then the return stroke begins, and a period termed the exhaust occurs, that is to say, steam passes out of the cylinder, into the condenser, where it is condensed at the pressure in the condenser, which is felt as a back pressure opposing the return of the piston. So far, all has been essentially reversible and identical with the corresponding parts of Carnot’s cycle.

But we cannot complete the cycle as Carnot’s cycle was completed. The existence of a separate condenser makes the fourth stage, that of adiabatic compression, impracticable, and the best we can do is to continue the exhaust until condensation is complete, and then return the condensed water to the boiler.

41. Rankine Cycle.—It follows that the ideal cycle of Carnot is not an appropriate standard with which to compare the action of a real steam engine. Instead of it we have, in the engine with separated organs, a cycle which is commonly called the Rankine cycle, which differs from the Carnot cycle only in this, that the stage of adiabatic compression, is wanting and its place is taken by a direct return of the condensed water to the boiler, a process which makes the water receive heat at various temperatures, ranging from the temperature of the condenser up to that of the boiler. The chief part of the heat which the working substance receives is still taken in at the upper limit of temperature, during the process of changing from water to steam. But a small part is taken in at lower temperatures, namely, in the heating of the feed water in its transfer to the boiler. Any heat so taken in has less availability for conversion into work than if it were taken in at the top of the range, and consequently the ideal efficiency of the cycle falls somewhat short of this ideal reached in the cycle of Carnot.

But the principle still applies that with respect to each portion of the heat that is taken in, the fraction convertible into work under ideally favourable conditions is measured by (τ−τ2)/τ, where τ is the absolute temperature at which that portion of heat is received, and τ2 is the temperature at which heat is rejected. Accordingly, we may investigate as follows the ideal performance of an engine following the Rankine cycle. Let δQ represent that portion of the whole heat which is taken in at any temperature τ. Then the greatest amount of work obtainable from that portion of heat is δQ(τ−τ2)/τ, and the whole amount of work ideally obtainable in the complete process is found by calculating, ΣδQ(τ−τ2)/τ where the summation includes all the heat that is taken in. In a steam engine using saturated steam the principal item in this sum is the latent heat L1, which is taken in at constant temperature τ1, during the change of state from water to steam. But there is, in addition, the heat taken in by the feed-water before it reaches the temperature at which steam is formed, and this may be represented as the sum of a series of elements σδτ taken in at varying temperatures τ, where σ is the specific heat of water. Thus if W represents the thermal equivalent of the work theoretically obtainable per ℔ of steam, under ideally favourable conditions,

W=Σσδτ(τ−τ2)/τ + L1(τ1−τ2)/τ1.

The experiments of Regnault show that σ, within the limits of temperature that obtain in boilers, is a nearly constant quantity, and no serious error will be introduced in this integration by treating it as a constant, with a value equal to the mean value, as determined by Regnault, between the limits of τ1 and τ2. On this basis

W=σ(τ1−τ2)−στ2 logετ1/τ2 + L1(τ1−τ2)/τ1.

It is usual to take σ as practically equal to 1, which makes

W=(τ−τ2)(1 + L1/τ1) − τ2 logετ1/τ2.