1911 Encyclopædia Britannica/Carpentry

CARPENTRY, the art and work of a carpenter (from Lat. carpentum, a carriage), a workman in wood, especially for building purposes. The labour of the sawyer is applied to the division of large pieces of timber or logs into forms and sizes to suit the purposes of the carpenter and joiner. His working-place is called a sawpit, and his most important tool is a pit-saw. A cross-cut saw, axes, dogs, files, compasses, lines, lampblack, blacklead, chalk and a rule may also be regarded as necessary to him. But this method of sawing timber is now only used in remote country places, and in modern practice logs, &c., are converted into planks and small pieces at saw-mills, which are equipped with modern machinery to drive all kinds of circular saws by electricity, steam or gas.

Carpentry or carpenters’ work has been divided into three principal branches—descriptive, constructive and mechanical. The first shows the lines or method for forming every species of work by the rules of geometry; the second comprises the practice of reducing the timber into particular forms, and joining the forms so produced in such a way as to make a complete whole according to the intention or design; and the third displays the relative strength of the timbers and the strains to which they are subjected by their disposition. Here we have merely to describe the practical details of the carpenter’s work in the operations of building. He is distinguished from the joiner by his operations being directed to the mere carcass of a building, to things which have reference to structure only. Almost everything the carpenter does to a building is absolutely necessary to its stability and efficiency, whereas the joiner does not begin his operations until the carcass is complete, and every article of joiners’ work might at any time be removed from a building without undermining it or affecting its most important qualities. Certainly in the practice of building a few things do occur regarding which it is difficult to determine to whose immediate province they belong, but the distinction is sufficiently broad for general purposes.

The carpenter frames or combines separate pieces of timber by scarfing, notching, cogging, tenoning, pinning and wedging, &c. The tools he uses are the rule, axe, adze, saws, mallet, hammers, chisels, gouges, augers, pincers, set squares, bevel, compasses, gauges, level, plumb rule, jack, trying and smoothing planes, rebate and moulding planes, and gimlets and wedges. The carpenter has little labour to put on to the stuff; his chief work consists in fixing and cutting the ends of timbers, the labour in preparing the timber being done by machinery.

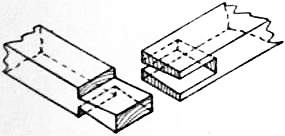

Fig. 1.—Lapped Joint.

Fig. 2.—Fished Joint.

Figs. 3, 4 and 5.—Scarf Joints.

Joints.—The joints in carpentry are various, and each is designed according to the thrust or strain put upon it. Those principally used are the following: lap, fished, scarf, notching, cogging, dovetailing, housing, halving, mortice and tenon, stub tenon, dovetailed tenon, tusk tenon, joggle, bridle, foxtail wedging, mitre, birdsmouth, built-up, dowel. Illustrations are given of the most useful joints in general use, and these, together with the descriptions, will enable a good idea to be formed of their respective merits and methods of application.

The lapped joint (fig. 1) is used for temporary structures in lengthening timbers and is secured with iron straps and bolts; a very common use of the lap joint is seen in scaffolding secured with cords and wedges.

The fished joint (fig. 2) is used for lengthening beams and is constructed by butting the ends of two pieces of timber together with an iron plate on top and bottom, and bolting through the timber; these iron connecting-plates are usually about 3 ft. long and 1/4 in. and 1/2 in. in thickness. This joint provides a good and cheap method of accomplishing its purpose.

The scarf joint (figs. 3, 4 and 5) is used for lengthening beams, and is made by cutting and notching the ends of timbers and lapping and fitting and bolting through. This method cuts into the timber, but is very strong and neat; in addition for extra strong work an iron fish-plate is used as in the fished joint.

The ends of floor joints and rafters are usually notched (fig. 6) over plates to obtain a good bearing and bring them to the required levels. Where one timber crosses another as in purlins, rafters, wood floor girders, plates, &c, both timbers are notched so as to fit over each other; this cogging (fig. 7) serves instead of fastenings. The timbers are held together with a spike. In this way they are not weakened, and the joint is a very good one for keeping them in position.

|

|

| Fig. 9.—Housing. | Fig. 10.—Halving. |

Dovetailing (fig. 8) is used for connecting angles of timber together, such as lantern curbs or linings, and is the strongest form. When an end of timber is let entirely into another timber it is said to be housed (fig. 9). Where timbers cross one another and require to be flush on one or both faces, sinkings are cut in each so as to fit over each other (halving); these can either be square (fig. 10), bevelled (fig. 11) or dovetailed sinkings (fig. 12). The end of one piece of timber cut so as to leave a third of the thickness forms a tenon, and the piece of timber which is to be joined to it has a mortice or slot cut through it to receive the tenon; the two are then wedged or pinned with wood pins (fig. 13).

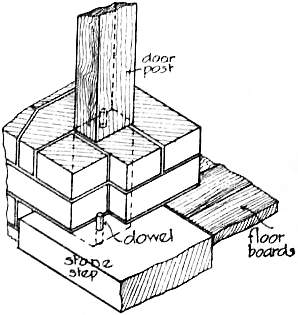

A stub tenon or joggle (fig. 14) is used for fixing a post to a sill; a sinking is cut in the sill and a tenon is cut on the foot of the post to fit into the sinking to keep the post from sliding.

The purpose of a dovetailed tenon (fig. 15) is to hold two pieces of wood together with mortice and tenon so that it can be taken apart when necessary. The tenon is cut dovetail shape, and a long mortice permits the wide part of the tenon to go through, and it is secured with wood wedges. Where the floor joists or rafters are trimmed round fires, wells, &c., the tusk tenon joint (fig. 16) is used for securing the trimmer joist. It is formed by cutting a tenon on the trimmer joist and passing it through the side of the trimming joist and fixing it with a wood key. Where large timbers are tusk tenoned together, the tenons do not pass right through, but are cut in about 4 in. and spiked.

A bridle joint or birdsmouth (fig. 17) is formed by cutting one end of timber either V shape or segmental, and morticing the centre of this shaped end. Similar sinkings are cut on the adjoining timber to fit one into the other; these are secured with pins and also various other forms of fastenings.

Fig. 20.—Method of supporting Centering for Concrete. Foxtail wedging (fig. 18) is a method very similar to mortice and tenon. But the tenon does not go through the full thickness of the timber; and also on the end of the tenon are inserted two wedges, so that when the tenon is driven home the wedges split it and wedge tightly into the mortice. This joint is used mostly in joinery. The mitre is a universal joint, used for connecting angles of timber as in the case of picture frames. Built-up joints involve a system of lapping and bolting and fishing, as in the case of temporary structures, for large spans of centering for arches, and for derrick cranes. Dowels are usually 3 or 4 in. long and driven into a circular hole in the foot of a door frame or post; the other end is let into a hole in the sill (fig. 19).

Centering.—Centering is temporary timber or framing erected so as to carry concrete floors or arches of brick or stone, &c.; when the work has set the centering is removed gradually. The centering for concrete floors is usually composed of scaffold boards resting on wood bearers (fig 20). One wood bearer rests along on top of the steel joists; through this bearer long bolts are suspended, and to the bottom of these bolts a second bearer is fixed, and on the bottom bearer the scaffold boards rest. Another method, not much used now, is to fit the boards to the size of the floor and prop them up on legs, but among other disadvantages this process takes up much space and is more costly.

Turning piece is a name given to centering required for turning an arch over (fig. 21); it is only 41/2 in. wide on the soffit or bed, and is generally cut out of a piece of 3 or 4 in. stuff, the top edge being made circular to the shape of the arch. It is kept in position whilst the arch is setting with struts from ground or sills and is nailed to the reveals, a couple of cross traces being wedged between. In the case of a semicircular or elliptical arch with 41/2 in. soffit this turning piece would be constructed of ribs cut out of 4 in. stuff with ties and braces. Or the ribs could be cut out of 1 in. stuff, in which case there must be one set of ribs outside and one inside secured with ties and braces; each set of ribs when formed of thin stuff is made of two thicknesses nailed together so as to lap the joints. For spans up to 15 ft. the thin ribs would be used, and for spans above 15 ft. ribs out of 4 in. stuff and upwards. For arches with 9 in. soffit and upwards, whether segmental or semicircular or elliptical, the centres are formed with the thin ribs and laggings up to 15 ft. span; above 15 ft. with 4 in. ribs and upwards (fig. 22).

The lower member of centres is called the tie, and is fixed so as to tie the extremities together and to keep the centre from spreading. Where the span is great, these ties, instead of being fixed straight, are given a rise so as to allow for access or traffic underneath. Braces are necessary to support the ribs from buckling in, and must be strong enough and so arranged as to withstand all stresses. Laggings are small pieces or strips of wood nailed on the ribs to form the surface on which to build the arch, and are spaced 1 in. apart for ordinary arches; for gauged arches they are nailed close together and the joints planed off. When centres are required to be taken down, the wedges upon which the centre rests are first removed so as to allow the arch to take its bearing gradually. Centres for brick sewers and vault arching are formed in the same way as previously mentioned, with ribs and laggings, but the thickness of the timbers depends upon the weight to be carried.

Floors.—For ordinary residential purposes floors are chiefly constructed of timber. Up to about the year 1895 nearly every modern building was constructed with wood joists, but because of evidence adduced by fire brigade experts and the serious fires that have occurred fire-resisting floors have been introduced. These consist of steel girders and joists, filled in with concrete or various patented brick materials in accordance with such by-laws as those passed by the London County Council and other authorities. The majority of the floors of public buildings, factories, schools, and large residential flats are now constructed of fire-resisting materials. There are two descriptions of flooring, single and double.

Single flooring (fig. 23) consists of one row of wood joists resting on a wall or partition at each end without any intermediate support, and receiving the floor boards on the upper surface and the ceiling on the underside. Joists should never be less than 2 in. thick, or Single flooring. they are liable to split when the floor brads are driven in; the thickness varies from 2 to 4 in. and the depth from 5 to 11 in. (see By-laws, below), the distance between each joist is usually 12 in. in the clear, but greater strength is obtained in a floor by having deep joists and placing them closer together. These floors are made firm and prevented from buckling by the use of strutting as mentioned hereafter.

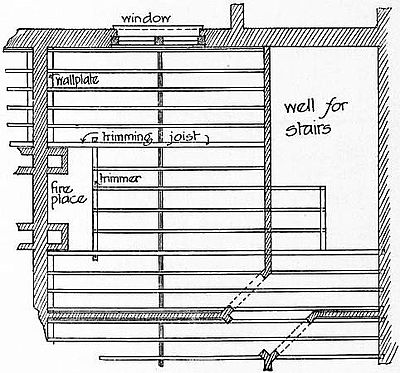

The efficiency of single flooring is materially affected by the necessity which constantly occurs in practice of trimming round fireplaces and flues, and round well holes such as lifts, staircases, &c. Trimming is a method of supporting the end of a joist by tenoning it into timber crossing it; the timber so tenoned is called the trimmer joist, and the timber morticed for the tenon of the trimmer is called the trimming joist, while the intermediate timbers tenoned into the trimmer are known as the trimmed joists. This system has to be resorted to when it is impossible to get a bearing on the wall.

A trimmer requires for the most part to be carried or supported at one or both ends by the trimming joists, and both the trimmer and the trimming joists are necessarily made stouter than if they had to bear no more than their own share of the stress. In the usual practice the trimmer and trimming joists are 1 in. thicker than the common joists, but there are special regulations and by-laws set out in the various districts and boroughs (see By-laws, below) to which attention must be given.

The principal objection to single flooring is that the sound passes through from floor to floor, so that, in some cases, conversation in one room can almost be understood in another. To stop the sound from passing through floors the remedy is to pug them (fig. 24). This consists in using rough boarding resting on fillets nailed to the sides of the joists about half-way up the depth of the joists, and then filling in on top of the boarding with slag wool usually 3 in. thick. Also to further prevent sound from passing through floors the flooring should be tongued and the ceiling should have a good thick floating coat, in poor work the stuff on ceilings is very stinted. In days gone by, ceiling joists were put at right angles to the floor joists, but this took up head room and was costly, and the arrangement is obsolete.

Double flooring (fig. 25) consists of single fir joists trimmed into steel girders; in earlier times a double floor consisted of fir joists called binding, bridging and ceiling joists, but these are very little used now and the single fir joists and steel girders have taken their place. Double flooring. Steel girders span from wall to wall, and on their flanges are bolted wood plates to receive the ends of the single joists which are notched over plates and run at right angles to the girders (fig. 26). The bearings of the joists on the wall also rest on wall plates, so as to get a level bed, and are sometimes notched over them. Wall plates, which are usually 41/2 in. × 3 in. and are bedded on walls in motar, take the ends of joists and distribute the weight along the wall. The plates bolted on the side of girders are of sizes to suit the width of the flanges.

The medieval floor (fig. 27) consisted of the framed floor with wood girders, binding, bridging and ceiling joists; and the underside of all the timbers was usually wrought, the girders and binders being boldly moulded and the other timbers either square or stop chamfered.

Flooring is strengthened by the use of strutting, either herring-bone (fig. 28) or solid (fig. 29). Herring-bone strutting consists of two pieces of timber, usually 2 in. × 2 in., fixed diagonally between each joist in continuous rows, the rows being about 6 ft. apart. Solid strutting consists of 11/4 in. boards, nearly the same depth as the joists and fitted tightly between the joists, and nailed in continuous rows 6 ft. apart. Where heavy weights are likely to be put on floors long bolts are passed through the centre of joists at the side of strutting; since this draws the strutting tightly together and does not produce any forcing stress on the walls, it is undoubtedly the best method.

Floors are usually constructed to carry the following loads (including weight of floor):—

Residences, 11/4 cwt. per foot super of floor space.

Public buildings, 11/2 cwt. per foot super of floor space.

Factories, 21/2 to 4 cwt. per foot super of floor space.

Local By-laws.—With regard to floor joists in domestic buildings, the following are required in the Hornsey district, in the north of London. The size of every common bearing floor joist up to 3 ft. long in clear shall be 3 in. × 21/2 in.; from 3 ft. to 6 ft. in clear it shall be 41/2 in. × 3 in.; from 6 ft. to 8 ft., 61/2 in. × 21/2 in.; from 8 ft. to 12 ft., 7 in. × 21/2 in., and so on according to the clear span. The Hornsey by-laws with regard to trimmers are as follows:—A trimmer joist shall not receive more than six common joists, and the thickness of a trimming joist receiving a trimmer at not more than 3 ft. from one end and of every trimmer joist shall be 1⁄8th of an inch greater than the thickness for a common joist of the same bearing for every common joist carried by a trimmer. For example, if the common joists are 7 in. × 21/2 in. and the trimmer has six joists trimmed into same, the size of trimmer would have to be 7 in. × 31/4 in. The Hornsey council also requires that the floor boards shall not be less than 7/8ths of an inch thick.

There is little difference in the requirements of the various localities. For example, the regulations of the Croydon council require that every common bearing joist for lengths up to 3 ft. 4 in. in clear shall be 3 in. × 21/2 in.; for lengths between 3 ft. 4 in. and 5 ft. 4 in., 4 in. × 2 in.; for lengths between 5 ft. 4 in. and 7 ft. 4 in., 4 in. × 3 in.; and so on according to the clear span. The Croydon by-laws with regard to trimmers are as follows:—A trimmer joist shall not receive more than six common joists, and the thickness of a trimming joist shall be 11/2 in. thicker than that for common joists of the same bearing, and the thickness of a trimmer joist shall be 1/4 in. thicker for every joist trimmed into same than the common joist. For example, if the common joists are 4 in. × 3 in. the trimming joists would have to be 4 in. × 41/4 in., and the trimmer joist would have to be 4 in. × 41/2 in.

Partitions.—Partitions are screens used to divide large floor spaces into smaller rooms and are sometimes constructed to carry the floors above by a system of trussing. They are built of various materials; those in use now are common stud partitions, bricknogged partitions, and solid deal and hardwood partitions, 41/2 in. brick walls or bricks laid on their sides, so making a 3 in. partition, and various patent partitions such as coke breeze concrete or hollow brick partitions (see Brickwork), iron and wire partitions, and plaster slab partitions (see Plasterwork).

There are two kinds of stud or quarter partitions, common and trussed.

Common partitions (fig. 30) simply act as a screen to divide one room from another, and do not carry any weight. They weigh about 25 ℔ per foot superficial including plastering on both sides, and are composed of 4 in. × 3 in. head and sill and 4 in. × 2 in. upright studs; Common partitions. 4 in. × 2 in. nogging pieces are fitted between the studs to keep them from bending in, and are placed parallel with the head, usually 4 ft. apart. Where door-openings occur in these partitions the studs next the opening are 4 in. × 3 in. Should the floor boards have been laid, the sill of the partition would be laid direct on them, but if the partitions are erected at the time of building the structure the sill should either rest directly over a joist, if parallel with it, or at right angles to the joists; should the position of the sill come between two joists, that is, parallel with them, then short pieces called bridging pieces of 4 in. × 2 in. stuff are wedged between the two joists and nailed to carry the sill.

Trussed partitions (fig. 31) are very similar to the last, but they are so built as to carry their own weight and also to support floors, and in addition have braces; the head and sill are larger, and calculated according to the clear bearing and the weight put upon them. Trussed partitions. There are two forms of trussing, namely, queen post (fig. 32) and king post (fig. 33).

Bricknogged partitions are formed in the same manner as the common stud partition, except that the studs are placed usually 18 or 27 in. apart in the clear instead of 12 in., and the 18 and 27 in. widths being multiples of a brick dimension, they are filled in with brickwork 41/2 in. thick and Brick-nogged partitions. always built in cement. These are used to prevent sound from passing from one room to another, and also to prevent fire from spreading, and are vermin-proof. Another method is to fill the space between the studs with coke breeze concrete instead of brickwork.

Timber partitions have the advantages that they are light and cheap and substantial, and the disadvantages that they are not fire-resisting or sound-resisting or vermin-proof; they should never be erected in damp positions such as the lower floors of buildings.

Solid wood partitions are used in offices and classrooms of schools, the upper portions usually being glazed; where these partitions enclose a staircase in a public building the London Building Act requires them to be of 2 in. hardwood, with only small panels of fire-resisting glass.

Timber Work.—Half timber work consists of a framework of timber; the upper storeys of suburban and country residences are often thus treated, and the spaces between the timbers are filled in with brickwork and plastered inside, and rough cast outside, though sometimes tiles are hung on the outside. In some instances in country places there is no filling between the timbers, and both sides are lath and plastered, and in others the timbers are solid, or facing pieces are simply plugged to the walls, the joints being pinned with hardwood pins. Half timber work (fig. 34) well designed has a very pleasing, homely and rural effect. The best and most durable wood to use is English oak worked smooth on the external face and usually painted; the by-laws of various authorities differ considerably as to the method of construction and in the restrictions as to its use. Some very fine early examples are to be seen in England, as at Holborn Bars, London, in the old parts of Bristol, and at Moreton Old Hall, near Congleton, Cheshire (see House, Plate IV. fig. 13).

Timber-framed permanent buildings are not used in the towns of England, not being allowed by the by-laws. In some English villages timber bungalows are allowed, plastered inside, and either rough cast outside, or with tiles, or with sheet iron painted. At the garden city of Letchworth, in Hertfordshire, there are a few timber-framed bungalows (erected about 1904 and originally intended to be used as week-end cottages), the outsides of which are covered with sheet iron and painted. Other instances of the temporary use of this kind of building are found in soldiers’ barracks, offices and chapels.

In America and the British colonies this class of building is very largely erected on the outskirts of the cities. In American practice in framing the walls of wooden buildings two distinct methods are used and are distinguished as “braced” and “balloon.”

The Braced (fig. 35) was the only kind in use previous to about the year 1850. In this method of framing the sills, posts, girts and plates are made of heavy timber morticed and pinned together and braced with 4 in. × 4 in. or 4 in. × 6 in. braces and common studding. To frame a building in this way it is necessary to cut all the pieces and make all the mortice holes on the ground, and then fit them together and raise a whole side at a time or at least one storey of it. The common studs are only one storey high.

The Balloon frame (fig. 36) is composed of much smaller scantlings and is more rapidly erected and less expensive. The method is to first lay the sill, generally 4 in. × 6 in., halved at the angles. After the floor is laid, the corner posts, usually 4 in. × 6 in., are erected and temporarily secured in place with the aid of stays. The common studs are then set up and spiked to the sill, and a temporary board nailed across their face on the inside. These common studs are the full height from sill to roof plate, and the second tier of floor joists are supported by notching a 11/4 in. × 7 in. board, called a false girt or ribbon, into their inside edge at the height to receive the floor joists. The ends of the joists are also placed against a stud and spiked. The tops of the studs are cut to a line, and a 2 in. × 4 in. plate is spiked on top, an additional 2 in. × 4 in. plate being placed on the top of the last breaking joint. Should the studs not be long enough to reach the plate, then short pieces are fished on with pieces of wood spiked on both sides. The diagram shows a portion of the framework of a two-storey house constructed in the manner described. In the balloon frame the timbers are held together entirely by nails and spikes, thus permitting them to be put up rapidly. The studs are doubled where windows or openings occur. In both these methods dwarf brick foundations should be built, upon which to rest the sill. For buildings of a superior kind a combination of the braced and balloon frames is sometimes adopted.

The sides of frame buildings are covered with siding, which is fastened to a sheathing of rough boards nailed to the studs. The siding may consist of matched boards placed diagonally, or of clapboards or weather boards—which are thin boards thicker at one edge than the other, and arranged horizontally with the thick edge downwards and overlapping the thin edge of the board below. Shingles or wooden tiles are also employed.

Authorities.—The following are the principal publications on carpentry: T. Tredgold, Carpentry; Peter Nicholson, Carpenter and Joiner; J. Newlands, Carpenter’s Assistant; J. Gwilt, Encyclopaedia of Architecture; Rivington, Building Construction (elementary and advanced); E. L. Tarbuck, Encyclopaedia of Practical Carpentry and Joinery; A. W. Pugin, Details of Ancient Timber Houses; Beresford Pite, Building Construction; J. P. Allen, Building Construction; H. Adams. Notes on Building; C. F. Mitchell, Building Construction (elementary and advanced); Burrell, Building Construction; F. E. Kidder, Building Construction (U.S.A.); E. E. Viollet le Duc, Dictionnaire; J. K. Krafft, L’Art de la charpente. (J. Bt.)