1911 Encyclopædia Britannica/Divers and Diving Apparatus

DIVERS and DIVING APPARATUS. To “dive” (Old Eng. dúfan, dŷfan; cf. “dip”) is to plunge under water, and in the ordinary procedure of swimmers is distinguished from simple plunging in that it involves remaining under the water for an interval of more or less duration before coming to the surface. In the article Swimming the sport of diving in this sense is considered. Here we are only concerned with diving as the function of a “diver,” whose business it is to go under water (in modern times, assisted by specially devised apparatus) in order to work.

Unassisted or Natural Diving.—The earliest reference to the practice of the art of diving for a purpose of utility occurs in the Iliad, 16, 745-750, where Patroclus compares the fall of Hector’s charioteer to the action of a diver diving for oysters. Thus it would seem that the art was known about 1000 years before the Christian era. Thucydides is the first to mention the employment of divers for mechanical work under water. He relates that divers were employed during the siege of Syracuse to saw down the barriers which had been constructed below the surface of the water with the object of obstructing and damaging any Grecian war vessels which might attempt to enter the harbour. At the siege of Tyre, divers were ordered by Alexander the Great to impede or destroy the submarine defences of the besieged as they were erected. The purpose of these obstructions was analogous to that of the submarine mine of to-day.

The employment of divers for the salvage of sunken property is first mentioned by Livy, who records that in the reign of Perseus considerable treasure was recovered from the sea. By a law of the Rhodians, their divers were allowed a proportion of the value recovered, varying with the risk incurred, or the depth from which the treasure was salved. For instance, if the diver raised it from a depth of eight cubits (12 ft.) he received one-third for himself; if from sixteen cubits (24 ft.) one half; but upon goods lost near the shore, and recovered from a depth of two cubits (36 in.), his share was only one tenth.

These are examples of unassisted diving as practised by the Ancients. Their primitive method, however, is still in vogue in some parts of the world—notably in the Ceylon pearl fisheries and in the Mediterranean sponge fisheries, and it may, therefore, be as well to mention the system adopted by the natural, or naked, diver of to-day.

The volume and power of respiration of the lungs vary in different individuals, some persons being able to hold their breath longer than others, so that it naturally follows that one man may be able to stay longer under water than another. The longest time that a natural diver has been known to remain beneath the surface is about two minutes. Some pearl and sponge divers rub their bodies with oil, and put wool, saturated with oil, in their ears. Others hold in their mouth a piece of sponge soaked in oil, which they renew every time they descend. It is doubtful, however, whether these expedients are beneficial. The men who dive in this primitive fashion take with them a flat stone with a hole in the centre; to this is attached a rope, which is secured to the diving boat and serves to guide them to particular spots below. When the diver reaches the sea bottom he tears off as much sponge within reach as possible, or picks up pearl shells, as the case may be, and then pulls the rope to indicate to the man in the boat that he wishes to be hauled up. But so exhausting is the work, and so severe the strain on the system, that, after a number of dives in deep water, the men often become insensible, and blood sometimes bursts from nose, ears and mouth.

Early Diving Appliances.—The earliest mention of any appliance for assisting divers is by Aristotle, who says that divers are sometimes provided with instruments for respiration through which they can draw air from above the water and which thus enable them to remain a long time under the sea (De Part. Anim. 2, 16), and also that divers breathe by letting down a metallic vessel which does not get filled with water but retains the air within it (Problem. 32, 5). It is also recorded that Alexander the Great made a descent into the sea in a machine called a colimpha, which had the power of keeping a man dry, and at the same time of admitting light. Pliny also speaks of divers engaged in the strategy of ancient warfare, who drew air through a tube, one end of which they carried in their mouths, whilst the other end was made to float on the surface of the water. Roger Bacon in 1240, too, is supposed to have invented a contrivance for enabling men to work under water; and in Vegetius’s De Re Militari (editions of 1511 and 1532, the latter in the British Museum) is an engraving representing a diver wearing a tight-fitting helmet to which is attached a long leathern pipe leading to the surface, where its open end is kept afloat by means of a bladder. This method of obtaining air during subaqueous operations was probably suggested by the action of the elephant when swimming; the animal instinctively elevates its trunk so that the end is above the surface of the water, and thus is enabled to take in fresh air at every inspiration.

A certain Repton invented “water armour” in the year 1617, but when tried it was found to be useless. G. A. Borelli in the year 1679 invented an apparatus which enabled persons to go to a certain depth under water, and he is credited with being the first to introduce means of forcing air down to the diver. For this purpose he used a large pair of bellows. John Lethbridge, a Devonshire man, in the year 1715 contrived “a watertight leather case for enclosing the person.” This leather case held about half a hogshead of air, and was so adapted as to give free play to arms and legs, so that the wearer could walk on the sea bottom, examine a sunken vessel and salve her cargo, returning to the surface when his supply of air was getting exhausted. It is said that Lethbridge made a considerable fortune by his invention. The next contrivance worthy of mention, and most nearly resembling the modern diving-dress, was an apparatus invented by Kleingert, of Breslau, in 1798. This consisted of an egg-ended metallic cylinder enveloping the head and the body to the hips. The diver was encased first of all in a leather jacket having tight-fitting arms, and in leather drawers with tight-fitting legs. To these the cylinder was fastened in such a way as to render the whole equipment airtight. The air supply was drawn through a pipe which was connected with the mouth of the diver by an ivory mouthpiece, the surface end being held above water after the manner mentioned in Vegetius, viz. by means of a floating bladder attached to it. The foul air escaped through another pipe held in a similar manner above the surface of the water, inhalation being performed by the mouth and exhalation by the nose, the act of inhalation causing the chest to expand and so to expel the vitiated air through the escape pipe. The diver was weighted when going under water, and when he wished to ascend he released one of his weights, and attached it to a rope which he held, and it was afterwards hauled up.

Modern Apparatus.—This, or equally cumbersome apparatus, was the only diving gear in use up till 1819, in which year Augustus Siebe (the founder of the firm of Siebe, Gorman & Co.), invented his “open” dress, worked in conjunction with an air force pump. This dress consisted of a metal helmet and shoulder-plate attached to a watertight jacket, under which, fitting more closely to the body, were worn trousers, or rather a combination suit reaching to the armpits. The helmet was fitted with an air inlet valve, to which one end of a flexible tube was attached, the other end being connected at the surface with a pump which supplied the diver with a constant stream of fresh air. The air, which kept the water well down, forced its way between the jacket and the under-garment, and escaped to the surface on exactly the same principle as that of the diving bell; hence the term “open” as applied to this dress.

Although most excellent work was accomplished with this dress—work which could not be attempted before its introduction—it was still far from perfect. It was absolutely necessary for the diver to maintain an upright, or but very slightly stooping, position whilst under water; if he stumbled and fell, the water filled his dress, and, unless quickly brought to the surface, he was in danger of being drowned. To overcome this and other defects, Siebe carried out a large number of experiments extending over several years, which culminated, in the year 1830, in the introduction of his “close” dress in combination with a helmet fitted with air inlet and regulating outlet valves.

Though, of course, vast improvements have been introduced since Siebe’s death, in 1872, the fact remains that his principle is in universal use to this day. The submarine work which it has been instrumental in accomplishing is incalculable. But some idea of the importance of the invention may be gathered from the fact that diving apparatus on Siebe’s principle is universally used to-day in harbour, dock, pier and breakwater construction, in the pearl and sponge fisheries, in recovering sunken ships, cargo and treasure, and that every ship in the British navy and in most foreign navies carries one set or more of diving apparatus.

A modern set of diving apparatus consists essentially of six parts:—(1) an air pump, (2) a helmet with breastplate, (3) a diving dress, (4) a pair of heavily weighted boots, (5) a pair of back and chest weights, (6) a flexible non-collapsible air tube.

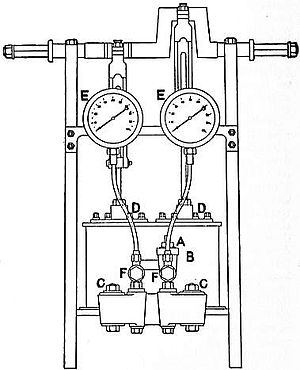

Air Pumps.—The type of air pump varies with the depth of water to which the diver has to descend; it will be readily understood that the greater the depth the greater the quantity of air required by the diver. The pattern most generally in favour amongst divers of all classes is a three-cylinder single-acting pump, which is suitable for almost every description of work which the diver may be called upon to perform, either in deep or shallow water. Another most useful type is a two-cylinder double-acting pump (figs. 1 and 2), which is designed to supply two divers working simultaneously in moderate depths of water, or one diver only in deep water. An air-distributing arrangement is fitted, whereby, when it is desired to send two men down together, each cylinder supplies air independently of the other; and when it is required to send one diver into deep water, the two cylinders are connected and the full volume of air from both is delivered to the one man. The same duty is also performed by a four-cylinder single-acting pump. Smaller pumps, having one double-acting or two single-acting cylinders, are also used for shallow water work.

In most cases these air pumps are worked by manual power; this method of working is rendered necessary by the fact that the machines are usually placed in small boats from which the divers work and on which other motive power is not available. In cases, however, where steam or electric power is available the pumps are sometimes worked by their means—more particularly on harbour and dock works. In such instances the air is not delivered direct from the pump to the diver, but is delivered into an intermediate steel receiver to which the diver’s air pipe is connected, the object being to ensure a reserve supply of air in case of a breakdown of the pump. Some of these combinations of pumps and motors are so arranged that, in the event of an accident to the motor, the pump can be thrown out of gear with it, and be immediately worked by hand power. Each pump is fitted with a gauge (or gauges), indicating not only the pressure of air which the pump is supplying, but also the depth of water at which the diver is working. The cylinders are water-jacketed to ensure the air delivered to the diver being cool, the water being drawn in and circulated round the cylinders by means of a small metal pump worked from an eccentric on the main crank-shaft. Filters are sometimes attached to the suction and delivery sides of the pumps to ensure the inlet of air being free from dirt, and the discharge of air free from dirt and oil.

|

| Fig. 2.—Pump in chest, ready for work. |

Helmet.—The helmet and breastplate (fig. 3) are made from highly planished tinned copper, with gun-metal valves and other fittings. The helmet is provided with a non-return air inlet valve to which the diver’s air pipe is connected; the air when it lifts the inlet valve passes through three conduits—one having its outlet over the front glass, the others their outlets over the side glasses. In this way the diver gets the air fresh as it enters the helmet, and at the same time it prevents condensation of his breath on the glasses and keeps them clear. There is a regulating air outlet valve by which the diver adjusts his supply of air according to his requirements in different depths of water; the valve is usually made to be adjusted by hand, but sometimes it is so constructed as to be operated by the diver knocking his head against it, the spindle being extended through to the inside of the helmet and fitted at its inner extremity with a button or disk. By unscrewing the valve, the diver allows air to escape, and thus the dress is deflated; by screwing it up the air is retained and the dress inflated. Thus the diver can control his specific gravity and rise or sink at will. In case by any chance the diver should inflate the dress inadvertently, and wish to get rid of the superfluous air quickly, he can do so by opening an emergency cock, which is fitted on the helmet. Plate glasses in gun-metal frames are also fitted to the helmet, two, one on each side, being permanently fixed, while one in front is made either to screw in and out, or to work on a hinged joint like a ship’s scuttle; the side glasses are usually protected by metal cross-bars, as is also sometimes the front glass. Some divers prefer unprotected glasses at the side of the helmet, instead of protected oval ones.

The breastplate is fitted on its outer edge with metal screws and bands. The disposition of the screws corresponds with that of the holes in the india-rubber collar of the diving dress described below. There are other methods of making a watertight joint between the diver’s breastplate and the diving dress, but, as these are only mechanical differences, it will suffice to describe the Siebe-Gorman apparatus, as exclusively adopted by the British government. Whatever the shape or design of the helmet or dress, Siebe’s principle is the one in universal use to-day.

The metal tabs are for carrying the diver’s lead weights, which are fitted with suitable clips; the hooks—one on each side of the helmet—are for keeping the ropes attached to the back weight in position. The helmet and breastplate are fitted at their lower and upper parts respectively with gun-metal segmental neck rings, which make it possible to connect these two main parts together by one-eighth of a turn, a catch at the back of the helmet preventing any chance of unscrewing. The small eyes at the top of the helmet are for securing the diver’s air pipe and life line in position and preventing them from swaying.

The Diving Dress is a combination suit which envelops the whole body from feet to neck. It is made of two layers of tanned twill with pure rubber between, and is fitted at the neck with a vulcanized india-rubber collar, or band, with holes punched in it corresponding to the screws in the breastplate. This collar, when clamped tightly between the bands and the breastplate by means of the nuts, ensures a watertight joint. The sleeves of the dress are fitted with vulcanized india-rubber cuffs, which, fitting tightly round the diver’s wrists, prevent the ingress of water at these parts also.

Boots.—These are generally made with leather uppers, beechwood inner soles and leaden outer soles, the latter being secured to the others by copper rivets. Heavy leather straps with brass buckles secure the boot to the foot. Each boot weighs about 16 ℔. Sometimes the main part of the boot-golosh, toe and heel, are in one brass casting, with leather upper part, heavy straps and brass buckles.

Lead Weights.—These weigh 40 ℔ each, and the diver wears one on his back, another on his chest. These weights and the heavy boots ensure the diver’s equilibrium when under water.

Belt and Knife and Small Tools.—Every diver wears a heavy waist-belt in which he carries a strong knife in metal case, and sometimes other small tools.

Air Pipe.—The diver’s air pipe is of a flexible, non-collapsible description, being made of alternate layers of strong canvas and vulcanized india-rubber, with steel or hard drawn metal wire embedded. At the ends are fitted gun-metal couplings, for connecting the pipe with the diver’s pump and helmet.

Signal Line.—The diver’s signal line (sometimes called life line) consists of a length of reverse laid Manila rope. In cases where the telephone apparatus is not used, the diver gives his signals by means of a series of pulls on the signal line in accordance with a prearranged code.

Telephonic Apparatus.—Without doubt one of the most useful adjuncts to the modern diving apparatus is the loud-sounding telephone (fig. 4), introduced by Siebe, Gorman & Co., which enables the diver to communicate viva voce with his attendant, and vice versa. In the British navy the type of submarine telephonic apparatus used is the Graham-Davis system. This is made on two plans, (1) a single set of instruments, for communication between one diver and his attendant direct, (2) an intercommunication set which is used where two divers are employed. With this type the attendant can speak to No. 1 or No. 2 diver separately, or with both at the same time, and vice versa; and No. 1 can be put in communication with No. 2 whilst they are under water, the attendant at the surface being able to hear what the men are saying. The advantages of such a system are obvious. It is more particularly useful where two divers are working one either side of a ship, or where the divers may be engaged upon the same piece of work, but out of sight of one another, or out of touch. It would prove its utility in a marked degree in cases where a diver got into difficulties; a second diver sent down to his assistance could receive and give verbal directions and thus greatly expedite the work of rescue.

|

| Fig. 4.—Diver’s Telephone Communication with the Surface. Q, Battery, with switch and bell in case. R, Attendant’s receiver and transmitter. |

The telephone instruments in the helmet consist of one or more loud-sounding receivers placed either in the crown of the helmet, or one on each side in close proximity to the diver’s ears. A transmitter of a special watertight pattern is placed between the front glass and one of the side glasses, and a contact piece, which, when the diver presses his chin against it, rings a bell at the surface, is fitted immediately below the front glass. A buzzer is sometimes fixed in the helmet to call the diver’s attention when the attendant wishes to speak, but as a rule the voice is transmitted so loudly that this device is unnecessary. A connexion, through which the insulated wires connecting the instruments pass, terminates in contact pieces, and the telephone cable, embedded in the diver’s signal line, is connected with it. The other end of the signal line is connected to a battery box at the surface. This box contains, besides the cells, a receiver and transmitter for the attendant, an electric bell, a terminal box, and a special switch, by means of which various communications between diver, or divers, and attendant are made. If, as is sometimes the case, the diver happens to be somewhat deaf, he can, whilst he is taking a message, stop the vibration of the outlet valve and the noise made by the escaping air, by merely pressing his finger on a spindle which passes through the disk of the valve, and thus momentarily ensure absolute silence.

Speaking Tube.—The rubber speaking tube which was the forerunner of the telephonic apparatus is now practically obsolete, though it is still used in isolated cases.

Submarine Electric Lamps.—Various forms of submarine lamps are used, from a powerful arc light to a self-contained hand lamp, the former giving about 2000 or 3000 candle-power, and requiring a steam-driven dynamo to supply the necessary current, the latter (fig. 5) giving a light of about 10 candle-power and having its own batteries, so that the diver carries both the light and its source in his hand. These submarine lamps are all constructed on the same principle, having the incandescent lamps, or carbons as the case may be, enclosed in a strong glass globe, the mechanism and connexions being fitted in a metal case above the globe, which is flanged and secured watertightly to the case.

Self-contained Diving Dress.—The object of the self-contained diving dress is to make the diver independent of air supply from the surface. The dress, helmet, boots and weights are of the ordinary pattern already described, but instead of obtaining his air supply by means of pumps and pipes, the diver is equipped with a knapsack consisting of a steel cylinder containing oxygen compressed to a pressure of 120 atmospheres (= about 1800 ℔) to the square inch, and chambers containing caustic soda or caustic potash. The helmet is connected to the chambers by tubes, and the oxygen cylinder is similarly connected to the chambers. The breath exhaled by the diver passes through a valve into the caustic soda, which absorbs the carbonic acid, and it is then again inhaled through another valve. This process of regeneration goes on automatically, the requisite amount of oxygen being restored to the breathed air in its passage through the chambers. This type of apparatus has been used for shallow water work, but the great majority of divers prefer the apparatus using pumps as the source of the air supply.

An emergency dress, using this self-contained system for breathing, has been designed by Messrs Fleuss and Davis, of the firm of Siebe, Gorman & Co., primarily as a life-saving apparatus, for enabling men to escape from disabled submarine boats.

The helmet diver is indispensable in connexion with harbour and dock construction, bridge-building, pearl and sponge fishing, wreck raising and the recovery of sunken cargo and treasure. Every ship in the British navy carries one set or more of diving apparatus, for use in ease of emergency, for clearing fouled propellers, cleaning valves or ship’s hull below the water line, repairing hulls if necessary, and recovering lost anchors, chains, torpedoes, &c.

Greatest Depths attained.—The greatest depth at which useful work has been performed by a diver is 182 ft. From this depth a Spanish diver, Angel Erostarbe, recovered £9000 in silver bars from the wreck of the steamer “Skyro,” sunk off Cape Finisterre; Alexander Lambert succeeded in salving £70,000 from the Spanish mail steamer “Alphonso XII,” sunk in 162 ft. of water off Las Palmas, Grand Canary; W. Ridyard recovered £50,000 in silver dollars from the “Hamilton Mitchell,” sunk off Leuconna Reef, China, in 150 ft. There are individual cases where much larger sums have been recovered, but those mentioned are particularly notable by reason of the great depth involved and stand out as the greatest depths at which good work has been done. The sponge fishers of the Mediterranean work at a maximum depth of about 150 ft., and the pearl divers of Australia at 120 ft. But submarine operations on the great majority of the harbour and dock works of the world are conducted at a depth of from 30 to 60 ft.

The weighted tools employed by divers differ very little from those used by the workmen on terra firma. Pneumatic tools, worked by compressed air conveyed from the surface through flexible tubes, are great aids, particularly in rock removal work. With the rock drill the diver bores a number of holes to a given depth, inserts in these the charges of dynamite or other explosive used, attaches one end of a wire to a detonator which is inserted in the charge, and then comes to the surface. The boat from which he works is then moved away from the scene of operations, paying out the wire attached to the detonators, and when at a safe distance the free end of the wire is connected to a magneto exploding machine, which is then set in motion.

A complete set of diving apparatus costs from £75 to £200, varying with the depth of water for which it is required.

The pay of a diver depends upon the nature of the work upon which he is engaged, and also upon the depth of the water. On harbour and dock work the average wage is 2s. to 2s. 6d. per hour; on wreck work from 3s. to 5s. an hour, according to depth; on treasure and cargo recovery so much per day, with a percentage on the value recovered, generally about 5%. The pearl fishers of Australia get so much per ton of shell, and the sponge fishers are also paid by results.

A problem which has been exercising the minds of those engaged in submarine work is the greatest depth at which it is possible to work, for, as is well known, many a fine vessel with valuable cargo and treasure is lying out of reach of the diver owing to the pressure which he would have to sustain were he to attempt to reach her. Mr Leonard Hill, and Drs Greenwood and J. J. R. Macleod conducted experiments in conjunction with Messrs Siebe, Gorman & Co., with a view to solving this problem, and their efforts have been attended with some considerable success. Dr J. S. Haldane has also carried out practical experiments for the British Admiralty, and under his supervision two naval officers have succeeded in reaching the unprecedented depth of 210 ft., at which depth the pressure is about 90 ℔ to the square inch.

Diving Bells.—Every one is familiar with the experiment of placing an inverted tumbler in a bowl of water, and seeing the water excluded from the tumbler by the air inside it. Perhaps it was to some such experiment as this that the conception of the diving bell was due. As is well known, the pressure of water increases with the depth, and for all practical purposes this pressure can be taken at 41/4 ℔ to every 10 ft. The following table shows the pressure at different depths below the surface of the water:—

| Depth. | Pressure. |

| 20 ft. | 81/2 lb to the sq. in. |

| 40 ” | 171/4 ” ” |

| 80 ” | 343/4 ” ” |

| 120 ” | 521/2 ” ” |

| 160 ” | 693/4 ” ” |

| 200 ” | 87 ” ” |

If a diving bell be sunk to a depth of, say, 33 ft., the air inside it will be compressed to about half its original volume, and the bell itself will be about half filled with water. But if a supply of air be maintained at a pressure equal to the depth of water at which the bell is submerged, not only will the water be kept down to the cutting edge, but the bell will be ventilated and it will be possible for its occupants to work for hours at a stretch.

Tradition gives Roger Bacon, in 1250, the credit for being the originator of the diving bell, but actual records are lost in antiquity. Of the records preserved to us, probably one of the most trustworthy is an account given in Kaspar Schott’s work, Technica curiosa, published in the year 1664, which quoted from one John Taisnier, who was in the service of Charles V. This account describes an experiment which took place at Toledo, Spain, in the year 1538, before the emperor and some thousands of spectators, when two Greeks descended into the water in a large “kettle,” suspended by ropes, with its mouth downwards. The “kettle” was equipoised by lead fixed round its mouth. The men came up dry, and a lighted candle, which they had taken down with them, was still burning.

Francis Bacon, in the Novum Organum, lib. ii., makes the following reference to a machine, or reservoir, of air to which labourers upon wrecks might resort whenever they required to take breath:—

“A hollow vessel, made of metal, was let down equally to the surface of the water, and thus carried with it to the bottom of the sea the whole of the air which it contained. It stood upon three feet—like a tripod—which were in length something less than the height of a man, so that the diver, when he was no longer able to contain his breath, could put his head into the vessel, and having filled his lungs again, return to his work.”

But it was to Dr Edmund Halley, secretary of the Royal Society, that undoubtedly the honour is due of having invented the first really practical diving bell. This is described in the Philosophical Transactions, 1717, in a paper on “The Art of Living Under Water by means of furnishing air at the bottom of the sea in any ordinary depth.” Halley’s bell was constructed of wood, and was covered with lead, which gave it the necessary sinking weight, and was so distributed as to ensure that it kept a perpendicular position when in the water. It was in the form of a truncated cone, 3 ft. in diameter at the top, 5 ft. at the bottom and 8 ft. high. In the roof a lens was introduced for admitting light, and also a tap to let out the vitiated air. Fresh air was supplied to the bell by means of two lead-lined barrels, each having a bung-hole in the top and bottom. To the hole in the top was fixed a leathern tube, weighted in such a manner that it always fell below the level of the bottom of the barrel so that no air could escape. When, however, the tube was turned up by the attendant in the bell, the pressure of the water rising through the hole in the bottom of the barrel, forced the air through the tube at the top and into the diving bell. These barrels were raised and lowered alternately, with such success that Halley says that he, with four others, remained at the bottom of the sea, at a depth of 9 to 10 fathoms, for an hour and a half at a time without inconvenience of any sort.

|

| Fig. 6.—Ordinary Diving Bell. |

This type of bell was used by John Smeaton in repairing the foundations of Hexham Bridge in 1778, but instead of weighted barrels, he introduced a force pump for supplying the necessary air. To Smeaton too we are indebted for the first diving bell plant in the form with which we are familiar to-day, that celebrated engineer having designed a square bell of iron, for use on the Ramsgate harbour works, in 1788. This bell, which measured 41/2 ft. in length, 3 ft. in width and 41/2 ft. in height, and weighed 21/2 tons, was made sufficiently heavy to sink by its own weight. It afforded room enough for two men to work, and was supplied with air by a force pump worked from a boat at the surface.

Though the diving bell has been largely superseded by the modern diving apparatus, it is still used on certain classes of work the magnitude of which justifies the expense entailed, for it is not only a question of the cost of the bell, but of the powerful steam-driven crane which is needed to lower and raise it, and also of the gantry on which the crane travels. Sometimes a barge or other vessel is used for working the bell.

At the present day, two types of diving bell are employed—the ordinary bell, and the air-lock bell, which, however, is not so largely used.

On the new national harbour works at Dover, four large diving bells of the ordinary type (fig. 6) were employed. These bells, in each of which from four to six men descended at a time, consisted of steel chambers, open at the bottom, measuring 17 ft. long by 101/2 ft. wide by 7 ft. high, and each weighed 35 tons. The ballast, which at once gives the necessary sinking weight to the bell and maintains its equilibrium, consisted of slabs of cast iron bolted to the walls of the bell, inside. Each bell was fitted with loud-sounding telephonic apparatus, by means of which the occupants could communicate either with the men attending the crane or the men looking after the air compressors at the surface. Electric lamps, supplied with current by a dynamo in the compressor room, gave the necessary light inside the bell. Seats and foot rails were provided for the men, and there were racks and hooks for the various tools. Suspended from the roof was an iron skip into which the men threw the excavated material, which was emptied out when the bell was brought to the surface. Air was supplied to the bells by means of steam-driven compressors worked in a house erected on the gantry. The air was delivered into a steel air receiver, and thence it passed through a flexible tube connected to a gun-metal inlet valve in the roof of the diving bell; the pressure of air was regulated according to the depth at which the bell happened to be working. The maximum depth on the Dover works was between 60 and 70 ft., = about 25-30 ℔ to the square inch. A bell was lowered by means of powerful steam-driven cranes, travelling on a gantry, to within a few feet of the water, and the men entered it from a boat. The bell then continued its descent to the bottom, where the men, with pick and shovel, levelled the sea bed ready to receive the large concrete blocks, weighing from 30 to 42 tons apiece. Having completed one section, the bell was moved along to another. The concrete blocks were then lowered and placed in position by helmet divers. The bell divers, clad in thick woollen suits and watertight thigh boots, worked in shifts of about three hours each, and were paid at the rate of from 1s. to 15d. per hour.

The cost of an ordinary diving bell, including air compressor, telephonic apparatus and electric light, is from £600 to £1500, according to size.

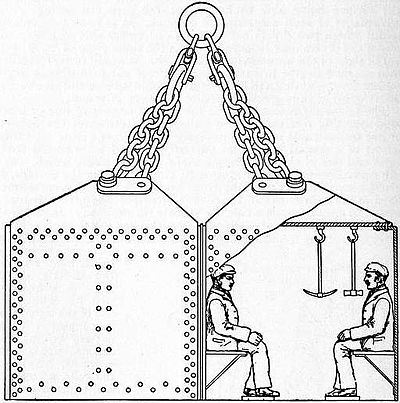

The Air-lock Diving Bell (fig. 7) comprises an iron or steel working chamber similar to the ordinary diving bell, but with the addition of a shaft attached to its roof. At the upper end of the shaft is an airtight door, and about 8 ft. below this is another similar door. When the bell divers wish to enter the bell, they pass through the first door and close it after them, and then open a cock or valve and gradually let into the space between the two doors compressed air from the working chamber in order to equalize the pressure; they then open the second door and pass down into the working chamber, closing the door after them. When returning to the surface they reverse the operation. It can readily be imagined that, owing to its unwieldy character, the employment of the air-lock bell is resorted to only in those cases where the nature of the sea bed necessitates its remaining on a given spot for some considerable time, as for instance in the excavation of hard rock to a given depth.

An air-lock bell supplied to the British Admiralty, for use in connexion with the laying of moorings at Gibraltar, has a working chamber measuring 15 ft. long by 101/2 ft. wide, by 71/2 ft. high, and a shaft 371/2 ft. high by 3 ft. in diameter. It is built of steel plates, with cast-iron ballast, and its total weight is about 46 tons. The bell is electrically lighted, and is fitted with telephonic apparatus communicating with the air-compressor room and lifting-winch room. It is worked through a well in the centre of a specially constructed steel barge 85 ft. long by 40 ft. beam, having a draught of 7 ft. 6 in. The wire ropes, for lowering and raising the bell, work over pulleys which are carried on a superstructure erected over the well. Two sets of air compressors are fitted on the barge—one set for supplying air to the bell, the other set for working a pneumatic rock drill inside the bell. The greatest depth at which this particular bell will work is 40 ft. The cost of the whole plant, including barge, was about £14,000.

The diving dress has, however, to a great extent supplanted the diving bell. This is due not only to the heavier cost of the latter, but more particularly to the greater mobility of the helmet diver. Bell divers are naturally limited to the area which their bell for the time being covers, whereas helmet divers can be distributed over different parts of a contract and work entirely independently of one another. The use of the diving bell is, therefore, practically limited to the work of levelling the sea bed, and the removal of rock.

See also the article Caisson Disease as regards the physiological effects of compressed air. (R. H. D.*)