1911 Encyclopædia Britannica/Elasticity

ELASTICITY. 1. Elasticity is the property of recovery of an original size or shape. A body of which the size, or shape, or both size and shape, have been altered by the application of forces may, and generally does, tend to return to its previous size and shape when the forces cease to act. Bodies which exhibit this tendency are said to be elastic (from Greek, ἐλαύνειν, to drive). All bodies are more or less elastic as regards size; and all solid bodies are more or less elastic as regards shape. For example: gas contained in a vessel, which is closed by a piston, can be compressed by additional pressure applied to the piston; but, when the additional pressure is removed, the gas expands and drives the piston outwards. For a second example: a steel bar hanging vertically, and loaded with one ton for each square inch of its sectional area, will have its length increased by about seven one-hundred-thousandths of itself, and its sectional area diminished by about half as much; and it will spring back to its original length and sectional area when the load is gradually removed. Such changes of size and shape in bodies subjected to forces, and the recovery of the original size and shape when the forces cease to act, become conspicuous when the bodies have the forms of thin wires or planks; and these properties of bodies in such forms are utilized in the construction of spring balances, carriage springs, buffers and so on.

It is a familiar fact that the hair-spring of a watch can be coiled and uncoiled millions of times a year for several years without losing its elasticity; yet the same spring can have its shape permanently altered by forces which are much greater than those to which it is subjected in the motion of the watch. The incompleteness of the recovery from the effects of great forces is as important a fact as the practical completeness of the recovery from the effects of comparatively small forces. The fact is referred to in the distinction between “perfect” and “imperfect” elasticity; and the limitation which must be imposed upon the forces in order that the elasticity may be perfect leads to the investigation of “limits of elasticity” (see §§ 31, 32 below). Steel pianoforte wire is perfectly elastic within rather wide limits, glass within rather narrow limits; building stone, cement and cast iron appear not to be perfectly elastic within any limits, however narrow. When the limits of elasticity are not exceeded no injury is done to a material or structure by the action of the forces. The strength or weakness of a material, and the safety or insecurity of a structure, are thus closely related to the elasticity of the material and to the change of size or shape of the structure when subjected to forces. The “science of elasticity” is occupied with the more abstract side of this relation, viz. with the effects that are produced in a body of definite size, shape and constitution by definite forces; the “science of the strength of materials” is occupied with the more concrete side, viz. with the application of the results obtained in the science of elasticity to practical questions of strength and safety (see Strength of Materials).

2. Stress.—Every body that we know anything about is always under the action of forces. Every body upon which we can experiment is subject to the force of gravity, and must, for the purpose of experiment, be supported by other forces. Such forces are usually applied by way of pressure upon a portion of the surface of the body; and such pressure is exerted by another body in contact with the first. The supported body exerts an equal and opposite pressure upon the supporting body across the portion of surface which is common to the two. The same thing is true of two portions of the same body. If, for example, we consider the two portions into which a body is divided by a (geometrical) horizontal plane, we conclude that the lower portion supports the upper portion by pressure across the plane, and the upper portion presses downwards upon the lower portion with an equal pressure. The pressure is still exerted when the plane is not horizontal, and its direction may be obliquely inclined to, or tangential to, the plane. A more precise meaning is given to “pressure” below. It is important to distinguish between the two classes of forces: forces such as the force of gravity, which act all through a body, and forces such as pressure applied over a surface. The former are named “body forces” or “volume forces,” and the latter “surface tractions.” The action between two portions of a body separated by a geometrical surface is of the nature of surface traction. Body forces are ultimately, when the volumes upon which they act are small enough, proportional to the volumes; surface tractions, on the other hand, are ultimately, when the surfaces across which they act are small enough, proportional to these surfaces. Surface tractions are always exerted by one body upon another, or by one part of a body upon another part, across a surface of contact; and a surface traction is always to be regarded as one aspect of a “stress,” that is to say of a pair of equal and opposite forces; for an equal traction is always exerted by the second body, or part, upon the first across the surface.

3. The proper method of estimating and specifying stress is a matter of importance, and its character is necessarily mathematical. The magnitudes of the surface tractions which compose a stress are estimated as so much force (in dynes or tons) per unit of area (per sq. cm. or per sq. in.). The traction across an assigned plane at an assigned point is measured by the mathematical limit of the fraction where denotes the numerical measure of the force exerted across a small portion of the plane containing the point, and denotes the numerical measure of the area of this portion, and the limit is taken by diminishing indefinitely. The traction may act as "tension," as it does in the case of a horizontal section of a bar supported at its upper end and hanging vertically, or as "pressure," as it does in the case of a horizontal section of a block resting on a horizontal plane, or again it may act obliquely or even tangentially to the separating plane. Normal tractions are reckoned as positive when they are tensions, negative when they are pressures. Tangential tractions are often called “shears” (see § 7 below). Oblique tractions can always be resolved, by the vector law, into normal and tangential tractions. In a fluid at rest the traction across any plane at any point is normal to the plane, and acts as pressure. For the complete specification of the “state of stress” at any point of a body, we should require to know the normal and tangential components of the traction across every plane drawn through the point. Fortunately this requirement can be very much simplified (see §§ 6, 7 below).

4. In general let denote the direction of the normal drawn in a specified sense to a plane drawn through a point of a body; and let denote the traction exerted across the plane, at the point by the portion of the body towards which is drawn upon the remaining portion. Then is a vector quantity, which has a definite magnitude (estimated as above by the limit of a fraction of the form ) and a definite direction. It can be specified completely by its components referred to fixed rectangular axes of When the direction of is that of the axis of in the positive sense, the components are denoted by and a similar notation is used when the direction of is that of or the suffix being replaced by or

5. Every body about which we know anything is always in a state of stress, that is to say there are always internal forces acting between the parts of the body, and these forces are exerted as surface tractions across geometrical surfaces drawn in the body. The body, and each part of the body, moves under the action of all the forces (body forces and surface tractions) which are exerted upon it; or remains at rest if these forces are in equilibrium. This result is expressed analytically by means of certain equations—the “equations of motion” or “equations of equilibrium” of the body.

Let denote the density of the body at any point, the components parallel to the axes of of the body forces, estimated as so much force per unit of mass; further let denote the components, parallel to the same axes, of the acceleration of the particle which is momentarily at the point (). The equations of motion express the result that the rates of change of the momentum, and of the moment of momentum, of any portion of the body are those due to the action of all the forces exerted upon the portion by other bodies, or by other portions of the same body. For the changes of momentum, we have three equations of the type

| (1) |

in which the volume integrations are taken through the volume of the portion of the body, the surface integration is taken over its surface, and the notation is that of § 4, the direction of being that of the normal to this surface drawn outwards. For the changes of moment of momentum, we have three equations of the type

| (2) |

The equations (1) and (2) are the equations of motion of any kind of body. The equations of equilibrium are obtained by replacing the right-hand members of these equations by zero.

6. These equations can be used to obtain relations between the values of for different directions When the equations are applied to a very small volume, it appears that the terms expressed by surface integrals would, unless they tend to zero limits in a higher order than the areas of the surfaces, be very great compared with the terms expressed by volume integrals. We conclude that the surface tractions on the portion of the body which is bounded by any very small closed surface, are ultimately in equilibrium. When this result is interpreted for a small portion in the shape of a tetrahedron, having three of its faces at right angles to the co-ordinate axes, it leads to three equations of the type

| (1) |

where is the direction of the normal (drawn outwards) to the remaining face of the tetrahedron, and denote the angles which this normal makes with the axes. Hence for any direction are expressed in terms of When the above result is interpreted for a very small portion in the shape of a cube, having its edges parallel to the co-ordinate axes, it leads to the equations

| (2) |

When we substitute in the general equations the particular results which are thus obtained, we find that the equations of motion take such forms as

| (3) |

and the equations of moments are satisfied identically. The equations of equilibrium are obtained by replacing the right-hand members by zero.

Fig. 17. A state of stress in which the traction across any plane of a set of parallel planes is normal to the plane, and that across any perpendicular plane vanishes, is described as a state of “simple tension” (“simple pressure” if the traction is negative). A state of stress in which the traction across any plane is normal to the plane, and the traction is the same for all planes passing through any point, is described as a state of “uniform tension” (“uniform pressure” if the traction is negative). Sometimes the phrases “isotropic tension” and “hydrostatic pressure” are used instead of “uniform” tension or pressure. The distinction between the two states, simple tension and uniform tension, is illustrated in fig. 1.

A state of stress in which there is purely tangential traction on a plane, and no normal traction on any perpendicular plane, is described as a state of “shearing stress.” The result (2) of § 6 shows that tangential tractions occur in pairs. If, at any point, there is tangential traction, in any direction, on a plane parallel to this direction, and if we draw through the point a plane at right angles to the direction of this traction, and therefore containing the normal to the first plane, then there is equal tangential traction on this second plane in the direction of the normal to the first plane. The result is illustrated in fig. 2, where a rectangular block is subjected on two opposite faces to opposing tangential tractions, and is held in equilibrium by equal tangential tractions applied to two other faces.

Fig. 2

Through any point there always pass three planes, at right angles to each other, across which there is no tangential traction. These planes are called the “principal planes of stress,” and the (normal) tractions across them the “principal stresses.” Lines, usually curved, which have at every point the direction of a principal stress at the point, are called “lines of stress.”

8. It appears that the stress at any point of a body is completely specified by six quantities, which can be taken to be the and of § 6. The first three are tensions (pressures if they are negative) across three planes parallel to fixed rectangular directions, and the remaining three are tangential tractions across the same three planes. These six quantities are called the “components of stress.” It appears also that the components of stress are connected with each other, and with the body forces and accelerations, by the three partial differential equations of the type (3) of § 6. These equations are available for the purpose of determining the state of stress which exists in a body of definite form subjected to definite forces, but they are not sufficient for the purpose (see § 38 below). In order to effect the determination it is necessary to have information concerning the constitution of the body, and to introduce subsidiary relations founded upon this information.

9. The definite mathematical relations which have been found to connect the components of stress with each other, and with other quantities, result necessarily from the formation of a clear conception of the nature of stress. They do not admit of experimental verification, because the stress within a body does not admit of direct measurement. Results which are deduced by the aid of these relations can be compared with experimental results. If any discrepancy were observed it would not be interpreted as requiring a modification of the concept of stress, but as affecting some one or other of the subsidiary relations which must be introduced for the purpose of obtaining the theoretical result.

10. Strain.—For the specification of the changes of size and shape which are produced in a body by any forces, we begin by defining the “average extension” of any linear element or “filament” of the body. Let be the length of the filament before the forces are applied, its length when the body is subjected to the forces. The average extension of the filament is measured by the fraction If this fraction is negative there is “contraction.” The “extension at a point” of a body in any assigned direction is the mathematical limit of this fraction when one end of the filament is at the point, the filament has the assigned direction, and its length is diminished indefinitely. It is clear that all the changes of size and shape of the body are known when the extension at every point in every direction is known.

The relations between the extensions in different directions around the same point are most simply expressed by introducing the extensions in the directions of the co-ordinate axes and the angles between filaments of the body which are initially parallel to these axes. Let denote the extensions parallel to the axes of and let denote the cosines of the angles between the pairs of filaments which are initially parallel to the axes of and and and Also let denote the extension in the direction of a line the direction cosines of which are Then, if the changes of size and shape are slight, we have the relation

The body which undergoes the change of size or shape is said to be “strained,” and the “strain” is determined when the quantities and defined above are known at every point of it. These quantities are called “components of strain.” The three of the type are extensions, and the three of the type are called “shearing strains” (see § 12 below).

11. All the changes of relative position of particles of the body are known when the strain is known, and conversely the strain can be determined when the changes of relative position are given. These changes can be expressed most simply by the introduction of a vector quantity to represent the displacement of any particle.

When the body is deformed by the action of any forces its particles pass from the positions which they occupied before the action of the forces into new positions. If are the co-ordinates of the position of a particle in the first state, its co-ordinates in the second state may be denoted by The quantities, are the “components of displacement.” When these quantities are small, the strain is connected with them by the equations

| . (1) | |||

13. Besides enabling us to express the extension in aniy direction and the changes of relative direction of any filaments of the body, the components of strain also express the changes of size of volumes and areas. In particular, the “cubical dilatation,” that is to say, the increase of volume per unit of volume, is expressed by the quantity or When this quantity is negative there is “compression.”

14. It is important to distinguish between two types of strain: the “rotational” type and the “irrotational” type. The distinction is illustrated in fig. 3, where the figure is obtained from the figure by contraction parallel to and extension parallel to and the figure can be obtained from by the same contraction and extension followed by a rotation through the angle In strains of the irrotational type there are at any point three filaments at right angles to each other, which are such that the particles which lie in them before strain continue to lie in them after strain. A small spherical element of the body with its centre at the point becomes a small ellipsoid with its axes in the directions of these three filaments. In the case illustrated in the figure, the lines of the filaments in question, when the figure is strained into the figure are and a line through at right angles to their plane. In strains of the rotational type, on the other hand, the single existing set of three filaments (issuing from a point) which cut each other at right angles both before and after strain do not retain their directions after strain, though one of them may do so in certain cases. In the figure, the lines of the filaments in question, when the figure is strained into are and a line at right angles to their plane before strain, and after strain they are and the same third line. A rotational strain can always be analysed into an irrotational strain (or “pure” strain) followed by a rotation.

Analytically, a strain is irrotational if the three quantities

15. Whether the strain is rotational or not, there is always one set of three linear elements issuing from any point which cut each other at right angles both before and after strain, If these directions are chosen as axes of the shearing strains vanish at this point. These directions are called the “principal axes of strain,” and the extensions in the directions of these axes the “principal extensions.”

16. It is very important to observe that the relations between components of strain and components of displacement imply relations between the components of strain themselves. If by any process of reasoning we arrive at the conclusion that the state of strain in a body is such and such a state, we have a test of the possibility or impossibility of our conclusion. The test is that, if the state of strain is a possible one, then there must be a displacement which can be associated with it in accordance with the equations (1) of § 11.

We may eliminate from these equations. When this is done we find that the quantities are connected by the two sets of equations

| . . . (1) | |

and

| . . (2) | |

These equations are known as the conditions of compatibility of strain-components. The components of strain which specify any possible strain satisfy them. Quantities arrived at in any way, and intended to be components of strain, if they fail to satisfy these equations, are not the components of any possible strain; and the theory or speculation by which they are reached must be modified or abandoned.

When the components of strain have been found in accordance with these and other necessary equations, the displacement is to be found by solving the equations (1) of § 11, considered as differential equations to determine The most general possible solution will differ from any other solution by terms which contain arbitrary constants, and these terms represent a possible displacement. This “complementary displacement” involves no strain, and would be a possible displacement of an ideal perfectly rigid body.

17. The relations which connect the strains with each other and with the displacement are geometrical relations resulting from the definitions of the quantities and not requiring any experimental verification. They do not admit of such verification, because the strain within a body cannot be measured. The quantities (belonging to the same category) which can be measured are displacements of points on the surface of a body. For example, on the surface of a bar subjected to tension we may make two fine transverse scratches, and measure the distance between them before and after the bar is stretched. For such measurements very refined instruments are required. Instruments for this purpose are called barbarously “extensometers,” and many different kinds have been devised. From measurements of displacement by an extensometer we may deduce the average extension of a filament of the bar terminated by the two scratches. In general, when we attempt to measure a strain, We really measure some displacements, and deduce the values, not of the strain at a point, but of the average extensions of some particular linear filaments of a body containing the point; and these filaments are, from the nature of the case, nearly always superficial filaments.

18. In the case of transparent materials such as glass there is available a method of studying experimentally the state of strain within a body. This method is founded upon the result that a piece of glass when strained becomes doubly refracting, with its optical principal axes at any point in the directions of the principal axes of strain (§ 15) at the point. When the piece has two parallel plane faces, and two of the principal axes of strain at any point are parallel to these faces, polarized light transmitted through the piece in a direction normal to the faces can be used to determine the directions of the principal axes of the strain at any point. If the directions of these axes are known theoretically the comparison of the experimental and theoretical results yields a test of the theory.

19. Relations between Stresses and Strains.—The problem of the extension of a bar subjected to tension is the one which has been most studied experimentally, and as a result of this study it is found that for most materials, including all metals except cast metals, the measurable extension is proportional to the applied tension, provided that this tension is not too great. In interpreting this result it is assumed that the tension is uniform over the cross-section of the bar, and that the extension of longitudinal filaments is uniform throughout the bar; and then the result takes the form of a law of proportionality connecting stress and strain: The tension is proportional to the extension. Similar results are found for the same materials when other methods of experimenting are adopted, for example, when a bar is supported at the ends and bent by an attached load and the deflexion is measured, or when a bar is twisted by an axial couple and the relative angular displacement of two sections is measured. We have thus very numerous experimental verifications of the famous law first enunciated by Robert Hooke in 1678 in the words “Ut Tensio sic vis”; that is, “the Power of any spring is in the same proportion as the Tension (—stretching) thereof.” The most general statement of Hooke’s Law in modern language would be:—Each of the six components of stress at any point of a body is a linear function of the six components of strain at the point. It is evident from what has been said above as to the nature of the measurement of stresses and strains that this law in all its generality does not admit of complete experimental verification, and that the evidence for it consists largely in the agreement of the results which are deduced from it in a theoretical fashion with the results of experiments. Of such results one of a general character may be noted here. If the law is assumed to be true, and the equations of motion of the body (§ 5) are transformed by means of it into differential equations for determining the components of displacement, these differential equations admit of solutions which represent periodic vibratory displacements (see § 85 below). The fact that solid bodies can be thrown into states of isochronous vibration has been emphasized by G. G. Stokes as a peremptory proof of the truth of Hooke’s Law.

20. According to the statement of the generalized Hooke’s Law the stress-components vanish when the strain-components vanish. The strain-components contemplated in experiments upon which the law is founded are measured from a zero of reckoning which corresponds to the state of the body subjected to experiment before the experiment is made, and the stress-components referred to in the statement of the law are those which are called into action by the forces applied to the body in the course of the experiment. No account is taken of the stress which must already exist in the body owing to the force of gravity and the forces by which the body is supported. When it is desired to take account of this stress it is usual to suppose that the strains which would be produced in the body if it could be freed from the action of gravity and from the pressures of supports are so small that the strains produced by the forces which are applied in the course of the experiment can be compounded with them by simple superposition. This supposition comes to the same thing as measuring the strain in the body, not from the state in which it was before the experiment, but from an ideal state (the “unstressed” state) in which it would be entirely free from internal stress, and allowing for the strain which would be produced by gravity and the supporting forces if these forces were applied to the body when free from stress. In most practical cases the initial strain to be allowed for is unimportant (see §§ 91-93 below).

21. Hooke’s law of proportionality of stress and strain leads to the introduction of important physical constants: the moduluses of elasticity of a body. Let a bar of uniform section (of area ) be stretched with tension which is distributed uniformly over the section, so that the stretching force is and let the bar be unsupported at the sides. The bar will undergo a longitudinal extension of magnitude where is a constant quantity depending upon the material. This constant is called Young's modulus after Thomas Young, who introduced it into the science in 1807. The quantity is of the same nature as a traction, that is to say, it is measured as a force estimated per unit of area. For steel it is about 2.04 × 1012 dynes per square centimetre, or about 13,000 tons per sq. in.

22. The longitudinal extension of the bar under tension is not the only strain in the bar. It is accompanied by a lateral contraction by which all the transverse filaments of the bar are shortened. The amount of this contraction is where is a certain number called Poisson’s ratio, because its importance was at first noted by S. D. Poisson in 1828. Poisson arrived at the existence of this contraction, and the corresponding number from theoretical considerations, and his theory led him to assign to the value Many experiments have been made with the view of determining with the result that it has been found to be different for different materials, although for very many it does not differ much from For steel the best value (Amagat’s) is 0.268. Poisson’s theory admits of being modified so as to agree with the results of experiment.

23. The behaviour of an elastic solid body, strained within the limits of its elasticity, is entirely determined by the constants and if the body is isotropic, that is to say, if it has the same quality in all directions around any point. Nevertheless it is convenient to introduce other constants which are related to the action of particular sorts of forces. The most important of these are the “modulus of compression” (or “bulk modulus”) and the “rigidity” (or “modulus of shear”). To define the modulus of compression, we suppose that a solid body of any form is subjected to uniform hydrostatic pressure of amount p. The state of stress within it will be one of uniform pressure, the same at all points, and the same in all directions round any point. There will be compression, the same at all points, and proportional to the pressure; and the amount of the compression can be expressed as The quantity is the modulus of compression. In this case the linear contraction in any direction is ; but in general the linear extension (or contraction) is not one-third of the cubical dilatation (or compression).

24. To define the rigidity, we suppose that a solid body is subjected to forces in such a way that there is shearing stress within it. For example, a cubical block may be subjected to opposing tractions on opposite faces acting in directions which are parallel to an edge of the cube and to both the faces. Let be the amount of the traction, and let it be uniformly distributed over the faces. As we have seen (§ 7), equal tractions must act upon two other faces in suitable directions in order to maintain equilibrium (see fig. 2 of § 7). The two directions involved may be chosen as axes of as in that figure. Then the state of stress will be one in which the stress-component denoted by is equal to and the remaining stress-components vanish; and the strain produced in the body is shearing strain of the type denoted by The amount of the shearing strain is and the quantity is the “rigidity.”

25. The modulus of compression and the rigidity are quantities of the same kind as Young’s modulus. The modulus of compression of steel is about 1.43 × 1012 dynes per square centimetre, the rigidity is about 8.19 × 1011 dynes per square centimetre. It must be understood that the values for different specimens of nominally the same material may differ considerably.

The modulus of compression and the rigidity of an isotropic material are connected with the Young’s modulus and Poisson’s ratio of the material by the equations

26. Whatever the forces acting upon an isotropic solid body may be, provided that the body is strained within its limits of elasticity, the strain-components are expressed in terms of the stress-components by the equations

| . . (1) | ||

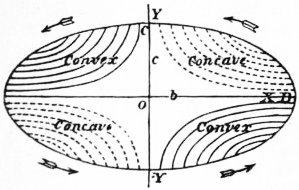

If we introduce a quantity of the same nature as or by the equation}}

| (2) |

| . (3) | ||

and then the behaviour of the body under the action of any forces depends upon the two constants and These two constants were introduced by G. Lamé in his treatise of 1852. The importance of the quantity had been previously emphasized by L. J. Vicat and G. G. Stokes.

27. The potential energy per unit of volume (often called the “resilience”) stored up in the body by the strain is equal to

or the equivalent expression

The former of these expressions is called the “strain-energy-function.”

28. The Young’s modulus of a material is often determined experimentally by the direct method of the extensometer (§ 17), but more frequently it is determined indirectly by means of a result obtained in the theory of the flexure of a bar (see §§ 47, 53 below). The rigidity is usually determined indirectly by means of results obtained in the theory of the torsion of a bar (see §§ 41, 42 below). The modulus of compression may be determined directly by means of the piezometer, as was done by E. H. Amagat, or it may be determined indirectly by means of a result obtained in the theory of a tube under pressure, as was done by A. Mallock (see § 78 below). The value of Poisson’s ratio is generally inferred from the relation connecting it with and or with and but it may also be determined indirectly by means of a result obtained in the theory of the flexure of a bar (§ 47 below), as was done by M. A. Cornu and A. Mallock, or directly by a modification of the extensometer method, as has been done recently by J. Morrow.

29. The elasticity of a fluid is always expressed by means of a single quantity of the same kind as the modulus of compression of a solid body. To any increment of pressure, which is not too great, there corresponds a proportional cubical compression, and the amount of this compression for an increment of pressure can be expressed as The quantity that is usually tabulated is the reciprocal of and it is called the coefficient of compressibility. It is the amount of compression per unit increase of pressure. As a physical quantity it is of the same dimensions as the reciprocal of a pressure (or of a force per unit of area). The pressures concerned are usually measured in atmospheres (1 atmosphere = 1.014 × 106 dynes per sq. cm.). For water the coefficient of compressibility, or the compression per atmosphere, is about 4.5 × 10–5. This gives for the value 2.22 × 1010 dynes per sq. cm. The Young’s modulus and the rigidity of a fluid are always zero.

30. The relations between stress and strain in a material which is not isotropic are much more complicated. In such a material the Young’s modulus depends upon the direction of the tension, and its variations about a point are expressed by means of a surface of the fourth degree. The Poisson’s ratio depends upon the direction of the contracted lateral filaments as well as upon that of the longitudinal extended ones. The rigidity depends upon both the directions involved in the specification of the shearing stress. In general there is no simple relation between the Young’s moduluses and Poisson’s ratios and rigidities for assigned directions and the modulus of compression. Many materials in common use, all fibrous woods for example, are actually aeolotropic (that is to say, are not isotropic), but the materials which are aeolotropic in the most regular fashion are natural crystals. The elastic behaviour of crystals has been studied exhaustively by many physicists, and in particular by W. Voigt. The strain-energy-function is a homogeneous quadratic function of the six strain-components, and this function may have as many as 21 independent coefficients, taking the place in the general case of the 2 coefficients which occur when the material is isotropic—a result first obtained by George Green in 1837. The best experimental determinations of the coefficients have been made indirectly by Voigt by means of results obtained in the theories of the torsion and flexure of aeolotropic bars.

31. Limits of Elasticity.—A solid body which has been strained by considerable forces does not in general recover its original size and shape completely after the forces cease to act. The strain that is left is called set. If set occurs the elasticity is said to be “imperfect,” and the greatest strain (or the greatest load) of any specified type, for which no set occurs, defines the “limit of perfect elasticity” corresponding to the specified type of strain, or of stress. All fluids and many solid bodies, such as glasses and crystals, as well as some metals (copper, lead, silver) appear to be perfectly elastic as regards change of volume within wide limits; but malleable metals and alloys can have their densities permanently increased by considerable pressures. The limits of perfect elasticity as regards change of shape, on the other hand, are very low, if they exist at all, for glasses and other hard, brittle solids; but a class of metals including copper, brass, steel, platinum are very perfectly elastic as regards distortion, provided that the distortion is not too great. The question can be tested by observation of the torsional elasticity of thin fibres or wires. The limits of perfect elasticity are somewhat ill-defined, because an experiment cannot warrant us in asserting that there is no set, but only that, if there is any set, it is too small to be observed.

32. A different meaning may be, and often is, attached to the phrase “limits of elasticity” in consequence of the following experimental result:—Let a bar be held stretched under a moderate tension, and let the extension be measured; let the tension be slightly increased and the extension again measured; let this process be continued, the tension being increased by equal increments. It is found that when the tension is not too great the extension increases by equal increments (as nearly as experiment can decide), but that, as the tension increases, a stage is reached in which the extension increases faster than it would do if it continued to be proportional to the tension. The beginning of this stage is tolerably well marked. Some time before this stage is reached the limit of perfect elasticity is passed; that is to say, if the load is removed it is found that there is some permanent set. The limiting tension beyond which the above law of proportionality fails is often called the “limit of linear elasticity.” It is higher than the limit of perfect elasticity. For steel bars of various qualities J. Bauschinger found for this limit values varying from 10 to 17 tons per square inch. The result indicates that, when forces which produce any kind of strain are applied to a solid body and are gradually increased, the strain at any instant increases proportionally to the forces up to a stage beyond that at which, if the forces were removed, the body would completely recover its original size and shape, but that the increase of strain ceases to be proportional to the increase of load when the load surpasses a certain limit. There would thus be, for any type of strain, a limit of linear elasticity, which exceeds the limit of perfect elasticity.

33. A body which has been strained beyond the limit of linear elasticity is often said to have suffered an “over-strain.” When the load is removed, the set which can be observed is not entirely permanent; but it gradually diminishes with lapse of time. This phenomenon is named “elastic after-working.” If, on the other hand, the load is maintained constant, the strain is gradually increased. This effect indicates a gradual flowing of solid bodies under great stress; and a similar effect was observed in the experiments of H. Tresca on the punching and crushing of metals. It appears that all solid bodies under sufficiently great loads become “plastic,” that is to say, they take a set which gradually increases with the lapse of time. No plasticity is observed when the limit of linear elasticity is not exceeded.

34. The values of the elastic limits are affected by overstrain. If the load is maintained for some time, and then removed, the limit of linear elasticity is found to be higher than before. If the load is not maintained, but is removed and then reapplied, the limit is found to be lower than before. During a period of rest a test piece recovers its elasticity after overstrain.

35. The effects of repeated loading have been studied by A. Wöhler, J. Bauschinger, O. Reynolds and others. It has been found that, after many repetitions of rather rapidly alternating stress, pieces are fractured by loads which they have many times withstood. It is not certain whether the fracture is in every case caused by the gradual growth of minute flaws from the beginning of the series of tests, or whether the elastic quality of the material suffers deterioration apart from such flaws. It appears, however, to be an ascertained result that, so long as the limit of linear elasticity is not exceeded, repeated loads and rapidly alternating loads do not produce failure of the material.

36. The question of the conditions of safety, or of the conditions in which rupture is produced, is one upon which there has been much speculation, but no completely satisfactory result has been obtained. It has been variously held that rupture occurs when the numerically greatest principal stress exceeds a certain limit, or when this stress is tension and exceeds a certain limit, or when the greatest difference of two principal stresses (called the “stress-difference”) exceeds a certain limit, or when the greatest extension or the greatest shearing strain or the greatest strain of any type exceeds a certain limit. Some of these hypotheses appear to have been disproved. It was held by G. F. Fitzgerald (Nature, Nov. 5, 1896) that rupture is not produced by pressure symmetrically applied all round a body, and this opinion has been confirmed by the recent experiments of A. Föppl. This result disposes of the greatest stress hypothesis and also of the greatest strain hypothesis. The fact that short pillars can be crushed by longitudinal pressure disposes of the greatest tension hypothesis, for there is no tension in the pillar. The greatest extension hypothesis failed to satisfy some tests imposed by H. Wehage, who experimented with blocks of wrought iron subjected to equal pressures in two directions at right angles to each other. The greatest stress difference hypothesis and the greatest shearing strain hypothesis would lead to practically identical results, and these results have been held by J. J. Guest to accord well with his experiments on metal tubes subjected to various systems of combined stress; but these experiments and Guest’s conclusion have been criticized adversely by O. Mohr, and the question cannot be regarded as settled. The fact seems to be that the conditions of rupture depend largely upon the nature of the test (tensional, torsional, flexural, or whatever it may be) that is applied to a specimen, and that no general formula holds for all kinds of tests. The best modern technical writings emphasize the importance of the limits of linear elasticity and of tests of dynamical resistance (§ 87 below) as well as of statical resistance.

37. The question of the conditions of rupture belongs rather to the science of the strength of materials than to the science of elasticity (§ 1); but it has been necessary to refer to it briefly here, because there is no method except the methods of the theory of elasticity for determining the state of stress or strain in a body subjected to forces. Whatever view may ultimately be adopted as to the relation between the conditions of safety of a structure and the state of stress or strain in it, the calculation of this state by means of the theory or by experimental means (as in § 18) cannot be dispensed with.

38. Methods of determining the Stress in a Body subjected to given Forces.—To determine the state of stress, or the state of strain, in an isotropic solid body strained within its limits of elasticity by given forces, we have to use (i.) the equations of equilibrium, (ii.) the conditions which hold at the bounding surface, (iii.) the relations between stress-components and strain-components, (iv.) the relations between strain-components and displacement. The equations of equilibrium are (with notation already used) three partial differential equations of the type

| (1) |

The conditions which hold at the bounding surface are three equations of the type

| (2) |

where denotes the direction of the outward-drawn normal to the bounding surface, and denotes the -component of the applied surface traction. The relations between stress-components and strain-components are expressed by either of the sets of equations (1) or (3) of § 26. The relations between, strain-components and displacement are the equations (1) of § 11, or the equivalent conditions of compatibility expressed in equations (1) and (2) of § 16.

39. We may proceed by either of two methods. In one method we eliminate the stress-components and the strain-components and retain only the components of displacement. This method leads (with notation already used) to three partial differential equations of the type

| (3) |

and three boundary conditions of the type

| (4) |

In the alternative method we eliminate the strain-components and the displacements. This method leads to a system of partial differential equations to be satisfied by the stress-components. In this system there are three equations of the type

| (1 bis) |

three of the type

| (5) |

and three of the type

| (6) |

the equations of the two latter types being necessitated by the conditions of compatibility of strain-components. The solutions of these equations have to be adjusted so that the boundary conditions of the type (2) may be satisfied.

40. It is evident that whichever method is adopted the mathematical problem is in general very complicated. It is also evident that, if we attempt to proceed by help of some intuition as to the nature of the stress or strain, our intuition ought to satisfy the tests provided by the above systems of equations. Neglect of this precaution has led to many errors. Another source of frequent error lies in the neglect of the conditions in which the above systems of equations are correct. They are obtained by help of the supposition that the relative displacements of the parts of the strained body are small. The solutions of them must therefore satisfy the test of smallness of the relative displacements.

41. Torsion.—As a first example of the application of the theory we take the problem of the torsion of prisms. This problem, considered first by C. A. Coulomb in 1784, was finally solved by B. de Saint-Venant in 1855. The problem is this:—A cylindrical or prismatic bar is held twisted by terminal couples; it is required to determine the state of stress and strain in the interior. When the bar is a circular cylinder the problem is easy. Any section is displaced by rotation about the central-line through a small angle, which is proportional to the distance of the section from a fixed plane at right angles to this line. This plane is a terminal section if one of the two terminal sections is not displaced. The angle through which the section rotates is where is a constant, called the amount of the twist; and this constant is equal to where is the twisting couple, and is the moment of inertia of the cross-section about the central-line. This result is often called “Coulomb’s law.” The stress within the bar is shearing stress, consisting, as it must, of two sets of equal tangential tractions on two sets of planes which are at right angles to each other. These planes are the cross-sections and the axial planes of the bar. The tangential traction at any point of the cross-section is directed at right angles to the axial plane through the point, and the tangential traction on the axial plane is directed parallel to the length of the bar. The amount of either at a distance r from the axis is or The result that can be used to determine experimentally, for may be measured and and are known.

42. When the cross-section of the bar is not circular it is clear that this solution fails; for the existence of tangential traction, near the prismatic bounding surface, on any plane which does not cut this surface at right angles, implies the existence of traction applied to this surface. We may attempt to modify the theory by retaining the supposition that the stress consists of shearing stress, involving tangential traction distributed in some way over the cross-sections. Such traction is obviously a necessary constituent of any stress-system which could be produced by terminal couples around the axis. We should then know that there must be equal tangential traction directed along the length of the bar, and exerted across some planes or other which are parallel to this direction. We should also know that, at the bounding surface, these planes must cut this surface at right angles. The corresponding strain would be shearing strain which could involve (i.) a sliding of elements of one cross-section relative to another, (ii.) a relative sliding of elements of the above mentioned planes in the direction of the length of the bar. We could conclude that there may be a longitudinal displacement of the elements of the cross-sections. We should then attempt to satisfy the conditions of the problem by supposing that this is the character of the strain, and that the corresponding displacement consists of (i.) a rotation of the cross-sections in their planes such as we found in the case of the circle, (ii.) a distortion of the cross-sections into curved surfaces by a displacement (w) which is directed normally to their planes and varies in some manner from point to point of these planes. We could show that all the conditions of the problem are satisfied by this assumption, provided that the longitudinal displacement (w), considered as a function of the position of a point (x, y) in the cross-section, satisfies the equation

| ∂2w | + | ∂2w | = 0, |

| ∂x2 | ∂y2 |

and the boundary condition

| ( | ∂w | − τy) cos(x,ν) + ( | ∂w | + τx) cos(y,ν) = 0, |

| ∂x | ∂y |

where τ denotes the amount of the twist, and ν the direction

of the normal to the boundary. The solution is known for a

great many forms of section. (In the particular case of a circular

section w vanishes.) The tangential traction at any point of

the cross-section is directed along the tangent to that curve

of the family ψ = const. which passes through the point, ψ being

the function determined by the equations

| ∂w | = τ ( | ∂ψ | + y ), | ∂w | = − τ ( | ∂ψ | + x ). |

| ∂x | ∂y | ∂y | ∂x |

The amount of the twist τ produced by terminal couples of magnitude G is G/C, where C is a constant, called the “torsional rigidity” of the prism, and expressed by the formula

| C = μ ( | ∂ψ | ) | 2 | + ( | ∂ψ | ) | 2 | dxdy, |

| ∂x | ∂y |

the integration being taken over the cross-section. When the coefficient of μ in the expression for C is known for any section, μ can be determined by experiment with a bar of that form of section.

|  |

| Fig. 4. | Fig. 5. |

43. The distortion of the cross-sections into curved surfaces is shown graphically by drawing the contour lines (w = const.). In general the section is divided into a number of compartments, and the portions that lie within two adjacent compartments are respectively concave and convex. This result is illustrated in the accompanying figures (fig. 4 for the ellipse, given by x2/b2 + y2/c2 = 1; fig. 5 for the equilateral triangle, given by (x + 1/3a) (x2 − 3y2 − 4/3ax + 4/9a2) = 0; fig. 6 for the square).

44. The distribution of the shearing stress over the cross-section is determined by the function ψ, already introduced. If we draw the curves ψ = const., corresponding to any form of section, for equidifferent values of the constant, the tangential traction at any point on the cross-section is directed along the tangent to that curve of the family which passes through the point, and the magnitude of it is inversely proportional to the distance between consecutive curves of the family. Fig. 7 illustrates the result in the case of the equilateral triangle. The boundary is, of course, one of the lines. The “lines of shearing stress” which can thus be drawn are in every case identical with the lines of flow of frictionless liquid filling a cylindrical vessel of the same cross-section as the bar, when the liquid circulates in the plane of the section with uniform spin. They are also the same as the contour lines of a flexible and slightly extensible membrane, of which the edge has the same form as the bounding curve of the cross-section of the bar, when the membrane is fixed at the edge and slightly deformed by uniform pressure.

|

| Fig. 6. |

|

| Fig. 7. |

45. Saint-Venant’s theory shows that the true torsional rigidity is in general less than that which would be obtained by extending Coulomb’s law (G = μτI) to sections which are not circular. For an elliptic cylinder of sectional area ω and moment of inertia I about its central-line the torsional rigidity is μω4 / 4π2I, and this formula is not far from being correct for a very large number of sections. For a bar of square section of side a centimetres, the torsional rigidity in C.G.S. units is (0.1406) μa4 approximately, μ being expressed in dynes per square centimetre. How great the defect of the true value from that given by extending Coulomb’s law may be in the case of sections with projecting corners is shown by the diagrams (fig. 8 especially no. 4). In these diagrams the upper of the two numbers under each figure indicates the fraction which the true torsional rigidity corresponding to the section is of that value which would be obtained by extending Coulomb’s law; and the lower of the two numbers indicates the ratio which the torsional rigidity for a bar of the corresponding section bears to that of a bar of circular section of the same material and of equal sectional area. These results have an important practical application, inasmuch as they show that strengthening ribs and projections, such as are introduced in engineering to give stiffness to beams, have the reverse of a good effect when torsional stiffness is an object, although they are of great value in increasing the resistance to bending. The theory shows further that the resistance to torsion is very seriously diminished when there is in the surface any dent approaching to a re-entrant angle. At such a place the shearing strain tends to become infinite, and some permanent set is produced by torsion. In the case of a section of any form, the strain and stress are greatest at points on the contour, and these points are in many cases the points of the contour which are nearest to the centroid of the section. The theory has also been applied to show that a longitudinal flaw near the axis of a shaft transmitting a torsional couple has little influence on the strength of the shaft, but that in the neighbourhood of a similar flaw which is much nearer to the surface than to the axis the shearing strain may be nearly doubled, and thus the possibility of such flaws is a source of weakness against which special provision ought to be made.

|

| Fig. 8.—Diagrams showing Torsional Rigidities. |

|

| Fig. 9. |

46. Bending of Beams.—As a second example of the application of the general theory we take the problem of the flexure of a beam. In this case also we begin by forming a simple intuition as to the nature of the strain and the stress. On the side of the beam towards the centre of curvature the longitudinal filaments must be contracted, and on the other side they must be extended. If we assume that the cross-sections remain plane, and that the central-line is unaltered in length, we see (at once from fig. 9) that the extensions (or contractions) are given by the formula y/R, where y denotes the distance of a longitudinal filament from the plane drawn through the unstrained central-line at right-angles to the plane of bending, and R is the radius of curvature of the curve into which this line is bent (shown by the dotted line in the figure). Corresponding to this strain there must be traction acting across the cross-sections. If we assume that there is no other stress, then the magnitude of the traction in question is Ey/R, where E is Young’s modulus, and it is tension on the side where the filaments are extended and pressure on the side where they are contracted. If the plane of bending contains a set of principal axes of the cross-sections at their centroids, these tractions for the whole cross-section are equivalent to a couple of moment EI/R, where I now denotes the moment of inertia of the cross-section about an axis through its centroid at right angles to the plane of bending, and the plane of the couple is the plane of bending. Thus a beam of any form of section can be held bent in a “principal plane” by terminal couples of moment M, that is to say by a “bending moment” M; the central-line will take a curvature M/EI, so that it becomes an arc of a circle of radius EI/M; and the stress at any point will be tension of amount My/I, where y denotes distance (reckoned positive towards the side remote from the centre of curvature) from that plane which initially contains the central-line and is at right angles to the plane of the couple. This plane is called the “neutral plane.” The restriction that the beam is bent in a principal plane means that the plane of bending contains one set of principal axes of the cross-sections at their centroids; in the case of a beam of rectangular section the plane would bisect two opposite edges at right angles. In order that the theory may hold good the radius of curvature must be very large.

|

| Fig. 10. |

|

| Fig. 11. |

47. In this problem of the bending of a beam by terminal couples the stress is tension, determined as above, and the corresponding strain consists therefore of longitudinal extension of amount My/EI or y/R (contraction if y is negative), accompanied by lateral contraction of amount σMy/EI or σy/R (extension if y is negative), σ being Poisson’s ratio for the material. Our intuition of the nature of the strain was imperfect, inasmuch as it took no account of these lateral strains. The necessity for introducing them was pointed out by Saint-Venant. The effect of them is a change of shape of the cross-sections in their own planes. This is shown in an exaggerated way in fig. 10, where the rectangle ABCD represents the cross-section of the unstrained beam, or a rectangular portion of this cross-section, and the curvilinear figure A′B′C′D′ represents in an exaggerated fashion the cross-section (or the corresponding portion of the cross-section) of the same beam, when bent so that the centre of curvature of the central-line (which is at right angles to the plane of the figure) is on the line EF produced beyond F. The lines A′B′ and C′D′ are approximately circles of radii R/σ, when the central-line is a circle of radius R, and their centres are on the line FE produced beyond E. Thus the neutral plane, and each of the faces that is parallel to it, becomes strained into an anticlastic surface, whose principal curvatures are in the ratio σ : 1. The general appearance of the bent beam is shown in an exaggerated fashion in fig. 11, where the traces of the surface into which the neutral plane is bent are dotted. The result that the ratio of the principal curvatures of the anticlastic surfaces, into which the top and bottom planes of the beam (of rectangular section) are bent, is Poisson’s ratio σ, has been used for the experimental determination of σ. The result that the radius of curvature of the bent central-line is EI/M is used in the experimental determination of E. The quantity EI is often called the “flexural rigidity” of the beam. There are two principal flexural rigidities corresponding to bending in the two principal planes (cf. § 62 below).

|

| Fig. 12. |

48. That this theory requires modification, when the load does not consist simply of terminal couples, can be seen most easily by considering the problem of a beam loaded at one end with a weight W, and supported in a horizontal position at its other end. The forces that are exerted at any section p, to balance the weight W, must reduce statically to a vertical force W and a couple, and these forces arise from the action of the part Ap on the part Bp (see fig. 12), i.e. from the stresses across the section at p. The couple is equal to the moment of the applied load W about an axis drawn through the centroid of the section p at right angles to the plane of bending. This moment is called the “bending moment” at the section, it is the product of the load W and the distance of the section from the loaded end, so that it varies uniformly along the length of the beam. The stress that suffices in the simpler problem gives rise to no vertical force, and it is clear that in addition to longitudinal tensions and pressures there must be tangential tractions on the cross-sections. The resultant of these tangential tractions must be a force equal to W, and directed vertically; but the direction of the traction at a point of the cross-section need not in general be vertical. The existence of tangential traction on the cross-sections implies the existence of equal tangential traction, directed parallel to the central-line, on some planes or other which are parallel to this line, the two sets of tractions forming a shearing stress. We conclude that such shearing stress is a necessary constituent of the stress-system in the beam bent by terminal transverse load. We can develop a theory of this stress-system from the assumptions (i.) that the tension at any point of the cross-section is related to the bending moment at the section by the same law as in the case of uniform bending by terminal couples; (ii.) that, in addition to this tension, there is at any point shearing stress, involving tangential tractions acting in appropriate directions upon the elements of the cross-sections. When these assumptions are made it appears that there is one and only one distribution of shearing stress by which the conditions of the problem can be satisfied. The determination of the amount and direction of this shearing stress, and of the corresponding strains and displacements, was effected by Saint-Venant and R. F. A. Clebsch for a number of forms of section by means of an analysis of the same kind as that employed in the solution of the torsion problem.

|

| Fig. 13. |

49. Let l be the length of the beam, x the distance of the section p from the fixed end A, y the distance of any point below the horizontal plane through the centroid of the section at A, then the bending moment at p is W (l − x), and the longitudinal tension P or Xx at any point on the cross-section is −W (l − x)y/I, and this is related to the bending moment exactly as in the simpler problem.

50. The expressions for the shearing stresses depend on the shape of the cross-section. Taking the beam to be of isotropic material and the cross-section to be an ellipse of semiaxes a and b (fig. 13), the a axis being vertical in the unstrained state, and drawing the axis z at right angles to the plane of flexure, we find that the vertical shearing stress U or Xy at any point (y, z) on any cross-section is

| 2W [(a2 − y2) {2a2 (1 + σ) + b2} − z2a2 (1 − 2σ)] | . |

| πa3b (1 + σ) (3a2 + b2) |

The resultant of these stresses is W, but the amount at the centroid, which is the maximum amount, exceeds the average amount, W/πab, in the ratio

If σ = 1/4, this ratio is 7/5 for a circle, nearly 4/3 for a flat elliptic bar with the longest diameter vertical, nearly 8/5 for a flat elliptic bar with the longest diameter horizontal.

In the same problem the horizontal shearing stress T or Zx at any point on any cross-section is of amount

| − | 4Wyz {a2 (1 + σ) + b2σ} | . |

| πa3b (1 + σ) (3a2 + b2) |

The resultant of these stresses vanishes; but, taking as before σ = 1/4, and putting for the three cases above a = b, a = 10b, b = 10a, we find that the ratio of the maximum of this stress to the average vertical shearing stress has the values 3/5, nearly 1/15, and nearly 4. Thus the stress T is of considerable importance when the beam is a plank.

As another example we may consider a circular tube of external radius r0 and internal radius r1. Writing P, U, T for Xx, Xy, Zx, we find

| P = − | 4W | (l − x)y, |

| π (r04 − r14) |

| U = | W | [ (3 + 2σ) { r02 + r12 − y2 − | r02 r12 | (y2 − z2) } − (1 − 2σ) z2 ] |

| 2(1 + σ) π (r04 − r14) | (y2 + z2)2 |

| T = − | W | { 1 + 2σ + (3 + 2σ) | r02 r12 | } yz; |

| (1 + σ) π (r04 − r14) | (y2 + z2)2 |

and for a tube of radius r and small thickness t the value of P and the maximum values of U and T reduce approximately to

The greatest value of U is in this case approximately twice its average value, but it is possible that these results for the bending of very thin tubes may be seriously at fault if the tube is not plugged, and if the load is not applied in the manner contemplated in the theory (cf. § 55). In such cases the extensions and contractions of the longitudinal filaments may be practically confined to a small part of the material near the ends of the tube, while the rest of the tube is deformed without stretching.

51. The tangential tractions U, T on the cross-sections are necessarily accompanied by tangential tractions on the longitudinal sections, and on each such section the tangential traction is parallel to the central line; on a vertical section z = const. its amount at any point is T, and on a horizontal section y = const. its amount at any point is U.

The internal stress at any point is completely determined by the components P, U, T, but these are not principal stresses (§ 7). Clebsch has given an elegant geometrical construction for determining the principal stresses at any point when the values of P, U, T are known.

|

| Fig. 14. |

From the point O (fig. 14) draw lines OP, OU, OT, to represent the stresses P, U, T at O, on the cross-section through O, in magnitude, direction and sense, and compound U and T into a resultant represented by OE; the plane EOP is a principal plane of stress at O, and the principal stress at right angles to this plane vanishes. Take M the middle point of OP, and with centre M and radius ME describe a circle cutting the line OP in A and B; then OA and OB represent the magnitudes of the two remaining principal stresses. On AB describe a rectangle ABDC so that DC passes through E; then OC is the direction of the principal stress represented in magnitude by OA, and OD is the direction of the principal stress represented in magnitude by OB.

|

| Fig. 15. |

52. As regards the strain in the beam, the longitudinal and lateral extensions and contractions depend on the bending moment in the same way as in the simpler problem; but, the bending moment being variable, the anticlastic curvature produced is also variable. In addition to these extensions and contractions there are shearing strains corresponding to the shearing stresses T, U. The shearing strain corresponding to T consists of a relative sliding parallel to the central-line of different longitudinal linear elements combined with a relative sliding in a transverse horizontal direction of elements of different cross-sections; the latter of these is concerned in the production of those displacements by which the variable anticlastic curvature is brought about; to see the effect of the former we may most suitably consider, for the case of an elliptic cross-section, the distortion of the shape of a rectangular portion of a plane of the material which in the natural state was horizontal; all the boundaries of such a portion become parabolas of small curvature, which is variable along the length of the beam, and the particular effect under consideration is the change of the transverse horizontal linear elements from straight lines such as HK to parabolas such as H′K′ (fig. 15); the lines HL and KM are parallel to the central-line, and the figure is drawn for a plane above the neutral plane. When the cross-section is not an ellipse the character of the strain is the same, but the curves are only approximately parabolic.

The shearing strain corresponding to U is a distortion which has the effect that the straight vertical filaments become curved lines which cut the longitudinal filaments obliquely, and thus the cross-sections do not remain plane, but become curved surfaces, and the tangent plane to any one of these surfaces at the centroid cuts the central line obliquely (fig. 16). The angle between these tangent planes and the central-line is the same at all points of the line; and, if it is denoted by 1/2π + s0, the value of s0 is expressible as

| shearing stress at centroid | , |

| rigidity of material |

and it thus depends on the shape of the cross-section; for the elliptic section of § 50 its value is

| 4W | 2a2 (1 + σ) + b2 | ; | |

| Eπab | 3a2 + b2 |

for a circle (with σ = 1/4) this becomes 7W / 2Eπa2. The vertical filament through the centroid of any cross-section becomes a cubical parabola, as shown in fig. 16, and the contour lines of the curved surface into which any cross-section is distorted are shown in fig. 17 for a circular section.

|

| Fig. 16. |

|

| Fig. 17. |

53. The deflection of the beam is determined from the equation

and the special conditions at the supported end; there is no alteration of this statement on account of the shears. As regards the special condition at an end which is encastrée, or built in, Saint-Venant proposed to assume that the central tangent plane of the cross-section at the end is vertical; with this assumption the tangent to the central line at the end is inclined downwards and makes an angle s0 with the horizontal (see fig. 18); it is, however, improbable that this condition is exactly realized in practice. In the application of the theory to the experimental determination of Young’s modulus, the small angle which the central-line at the support makes with the horizontal is an unknown quantity, to be eliminated by observation of the deflection at two or more points.

54. We may suppose the displacement in a bent beam to be produced by the following operations: (1) the central-line is deflected into its curved form, (2) the cross-sections are rotated about axes through their centroids at right angles to the plane of flexure so as to make angles equal to 1/2π + s0 with the central-line, (3) each cross-section is distorted in its own plane in such a way that the appropriate variable anticlastic curvature is produced, (4) the cross-sections are further distorted into curved surfaces. The contour lines of fig. 17 show the disturbance from the central tangent plane, not from the original vertical plane.

55. Practical Application of Saint-Venant’s Theory.—The theory above described is exact provided the forces applied to the loaded end, which have W for resultant, are distributed over the terminal section in a particular way, not likely to be realized in practice; and the application to practical problems depends on a principle due to Saint-Venant, to the effect that, except for comparatively small portions of the beam near to the loaded and fixed ends, the resultant only is effective, and its mode of distribution does not seriously affect the internal strain and stress. In fact, the actual stress is that due to forces with the required resultant distributed in the manner contemplated in the theory, superposed upon that due to a certain distribution of forces on each terminal section which, if applied to a rigid body, would keep it in equilibrium; according to Saint-Venant’s principle, the stresses and strains due to such distributions of force are unimportant except near the ends. For this principle to be exactly applicable it is necessary that the length of the beam should be very great compared with any linear dimension of its cross-section; for the practical application it is sufficient that the length should be about ten times the greatest diameter.

56. In recent years the problem of the bending of a beam by loads distributed along its length has been much advanced. It is now practically solved for the case of a load distributed uniformly, or according to any rational algebraic law, and it is also solved for the case where the thickness is small compared with the length and depth, as in a plate girder, and the load is distributed in any way. These solutions are rather complicated and difficult to interpret. The case which has been worked out most fully is that of a transverse load distributed uniformly along the length of the beam. In this case two noteworthy results have been obtained. The first of these is that the central-line in general suffers extension. This result had been found experimentally many years before. In the case of the plate girder loaded uniformly along the top, this extension is just half as great as the extension of the central-line of the same girder when free at the ends, supported along the base, and carrying the same load along the top. The second noteworthy result is that the curvature of the strained central-line is not proportional to the bending moment. Over and above the curvature which would be found from the ordinary relation—

|

| Fig. 18. |

there is an additional curvature which is the same at all the cross-sections. In ordinary cases, provided the length is large compared with any linear dimension of the cross-section, this additional curvature is small compared with that calculated from the ordinary formula, but it may become important in cases like that of suspension bridges, where a load carried along the middle of the roadway is supported by tensions in rods attached at the sides.

57. When the ordinary relation between the curvature and the bending moment is applied to the calculation of the deflection of continuous beams it must not be forgotten that a correction of the kind just mentioned may possibly be requisite. In the usual method of treating the problem such corrections are not considered, and the ordinary relation is made the basis of the theory. In order to apply this relation to the calculation of the deflection, it is necessary to know the bending moment at every point; and, since the pressures of the supports are not among the data of the problem, we require a method of determining the bending moments at the supports either by calculation or in some other way. The calculation of the bending moment can be replaced by a method of graphical construction, due to Mohr, and depending on the two following theorems:—

(i.) The curve of the central-line of each span of a beam, when the bending moment M is given,[1] is identical with the catenary or funicular curve passing through the ends of the span under a (fictitious) load per unit length of the span equal to M/EI, the horizontal tension in the funicular being unity.

(ii.) The directions of the tangents to this funicular curve at the ends of the span are the same for all statically equivalent systems of (fictitious) load.

When M is known, the magnitude of the resultant shearing stress at any section is dM/dx, where x is measured along the beam.

|

| Fig. 19. |

58. Let l be the length of a span of a loaded beam (fig. 19), M1 and M2 the bending moments at the ends, M the bending moment at a section distant x from the end (M1), M′ the bending moment at the same section when the same span with the same load is simply supported; then M is given by the formula

| M = M′ + M1 | l − x | + M2 | x | , |

| l | l |

|

| Fig. 20. |

and thus a fictitious load statically equivalent to M/EI can be easily found when M′ has been found. If we draw a curve (fig. 20) to pass through the ends of the span, so that its ordinate represents the value of M′/EI, the corresponding fictitious loads are statically equivalent to a single load, of amount represented by the area of the curve, placed at the point of the span vertically above the centre of gravity of this area. If PN is the ordinate of this curve, and if at the ends of the span we erect ordinates in the proper sense to represent M1/EI and M2/EI, the bending moment at any point is represented by the length PQ.[2] For a uniformly distributed load the curve of M′ is a parabola M′ = 1/2wx (l − x), where w is the load per unit of length; and the statically equivalent fictitious load is 1/12wl3 / EI placed at the middle point G of the span; also the loads statically equivalent to the fictitious loads M1 (l − x) / lEI and M2x / lEI are 1/2M1l / EI and 1/2M2l / EI placed at the points g, g′ of trisection of the span. The funicular polygon for the fictitious loads can thus be drawn, and the direction of the central-line at the supports is determined when the bending moments at the supports are known.

|

| Fig. 21. |

|

| Fig. 22. |

|

| Fig. 23. |

59. When there is more than one span the funiculars in question may be drawn for each of the spans, and, if the bending moments at the ends of the extreme spans are known, the intermediate ones can be determined. This determination depends on two considerations: (1) the fictitious loads corresponding to the bending moment at any support are proportional to the lengths of the spans which abut on that support; (2) the sides of two funiculars that end at any support coincide in direction. Fig. 21 illustrates the method for the case of a uniform beam on three supports A, B, C, the ends A and C being freely supported. There will be an unknown bending moment M0 at B, and the system[3] of fictitious loads is 1/12wAB3/EI at G the middle point of AB, 1/12wBC3 / EI at G′ the middle point of BC, −1/2M0AB / EI at g and −1/2M0BC / EI at g′, where g and g′ are the points of trisection nearer to B of the spans AB, BC. The centre of gravity of the two latter is a fixed point independent of M0, and the line VK of the figure is the vertical through this point. We draw AD and CE to represent the loads at G and G′ in magnitude; then D and E are fixed points. We construct any triangle UVW whose sides UV, UW pass through D, B, and whose vertices lie on the verticals gU, VK, g′W; the point F where VW meets DB is a fixed point, and the lines EF, DK are the two sides (2, 4) of the required funiculars which do not pass through A, B or C. The remaining sides (1, 3, 5) can then be drawn, and the side 3 necessarily passes through B; for the triangle UVW and the triangle whose sides are 2, 3, 4 are in perspective.

The bending moment M0 is represented in the figure by the vertical line BH where H is on the continuation of the side 4, the scale being given by

| BH | = | 1/2M0BC | ; |

| CE | 1/12wBC3 |

this appears from the diagrams of forces, fig. 22, in which the oblique lines are marked to correspond to the sides of the funiculars to which they are parallel.

In the application of the method to more complicated cases there are two systems of fixed points corresponding to F, by means of which the sides of the funiculars are drawn.

60. Finite Bending of Thin Rod.—The equation