1911 Encyclopædia Britannica/Glass

GLASS (O.E. glæs, cf. Ger. Glas, perhaps derived from an old Teutonic root gla-, a variant of glo-, having the general sense of shining, cf. “glare,” “glow”), a hard substance, usually transparent or translucent, which from a fluid condition at a high temperature has passed to a solid condition with sufficient rapidity to prevent the formation of visible crystals. There are many varieties of glass differing widely in chemical composition and in physical qualities. Most varieties, however, have certain qualities in common. They pass through a viscous stage in cooling from a state of fluidity; they develop effects of colour when the glass mixtures are fused with certain metallic oxides; they are, when cold, bad conductors both of electricity and heat, they are easily fractured by a blow or shock and show a conchoidal fracture; they are but slightly affected by ordinary solvents, but are readily attacked by hydrofluoric acid.

The structure of glass has been the subject of repeated investigations. The theory most widely accepted at present is that glass is a quickly solidified solution, in which silica, silicates, borates, phosphates and aluminates may be either solvents or solutes, and metallic oxides and metals may be held either in solution or in suspension. Long experience has fixed the mixtures, so far as ordinary furnace temperatures are concerned, which produce the varieties of glass in common use. The essential materials of which these mixtures are made are, for English flint glass, sand, carbonate of potash and red lead; for plate and sheet glass, sand, carbonate or sulphate of soda and carbonate of lime; and for Bohemian glass, sand, carbonate of potash and carbonate of lime. It is convenient to treat these glasses as “normal” glasses, but they are in reality mixtures of silicates, and cannot rightly be regarded as definite chemical compounds or represented by definite chemical formulae.

The knowledge of the chemistry of glass-making has been considerably widened by Dr F. O. Schott’s experiments at the Jena glass-works. The commercial success of these works has demonstrated the value of pure science to manufactures.

The recent large increase in the number of varieties of glass has been chiefly due to developments in the manufacture of optical glass. Glasses possessing special qualities have been required, and have been supplied by the introduction of new combinations of materials. The range of the specific gravity of glasses from 2.5 to 5.0 illustrates the effect of modified compositions. In the same way glass can be rendered more or less fusible, and its stability can be increased both in relation to extremes of temperature and to the chemical action of solvents.

The fluidity of glass at a high temperature renders possible the processes of ladelling, pouring, casting and stirring. A mass of glass in a viscous state can be rolled with an iron roller like dough; can be rendered hollow by the pressure of the human breath or by compressed air; can be forced by air pressure, or by a mechanically driven plunger, to take the shape and impression of a mould; and can be almost indefinitely extended as solid rod or as hollow tube. So extensible is viscous glass that it can be drawn out into a filament sufficiently fine and elastic to be woven into a fabric.

Glasses are generally transparent but may be translucent or opaque. Semi-opacity due to crystallization may be induced in many glasses by maintaining them for a long period at a temperature just insufficient to cause fusion. In this way is produced the crystalline, devitrified material, known as Réaumur’s porcelain. Semi-opacity and opacity are usually produced by the addition to the glass-mixtures of materials which will remain in suspension in the glass, such as oxide of tin, oxide of arsenic, phosphate of lime, cryolite or a mixture of felspar and fluorspar.

Little is known about the actual cause of colour in glass beyond the fact that certain materials added to and melted with certain glass-mixtures will in favourable circumstances produce effects of colour. The colouring agents are generally metallic oxides. The same oxide may produce different colours with different glass-mixtures, and different oxides of the same metal may produce different colours. The purple-blue of cobalt, the chrome green or yellow of chromium, the dichroic canary-colour of uranium and the violet of manganese, are constant. Ferrous oxide produces an olive green or a pale blue according to the glass with which it is mixed. Ferric oxide gives a yellow colour, but requires the presence of an oxidizing agent to prevent reduction to the ferrous state. Lead gives a pale yellow colour. Silver oxide, mixed as a paint and spread on the surface of a piece of glass and heated, gives a permanent yellow stain. Finely divided vegetable charcoal added to a soda-lime glass gives a yellow colour. It has been suggested that the colour is due to sulphur, but the effect can be produced with a glass mixture containing no sulphur, free or combined, and by increasing the proportion of charcoal the intensity of the colour can be increased until it reaches black opacity. Selenites and selenates give a pale pink or pinkish yellow. Tellurium appears to give a pale pink tint. Nickel with a potash-lead glass gives a violet colour, and a brown colour with a soda-lime glass. Copper gives a peacock-blue which becomes green if the proportion of the copper oxide is increased. If oxide of copper is added to a glass mixture containing a strong reducing agent, a glass is produced which when first taken from the crucible is colourless but on being reheated develops a deep crimson-ruby colour. A similar glass, if its cooling is greatly retarded, produces throughout its substance minute crystals of metallic copper, and closely resembles the mineral called avanturine. There is also an intermediate stage in which the glass has a rusty red colour by reflected light, and a purple-blue colour by transmitted light. Glass containing gold behaves in almost precisely the same way, but the ruby glass is less crimson than copper ruby glass. J. E. C. Maxwell Garnett, who has studied the optical properties of these glasses, has suggested that the changes in colour correspond with changes effected in the structure of the metals as they pass gradually from solution in the glass to a state of crystallization.

Owing to impurities contained in the materials from which glasses are made, accidental coloration or discoloration is often produced. For this reason chemical agents are added to glass mixtures to remove or neutralize accidental colour. Ferrous oxide is the usual cause of discoloration. By converting ferrous into ferric oxide the green tint is changed to yellow, which is less noticeable. Oxidation may be effected by the addition to the glass mixture of a substance which gives up oxygen at a high temperature, such as manganese dioxide or arsenic trioxide. With the same object, red lead and saltpetre are used in the mixture for potash-lead glass. Manganese dioxide not only acts as a source of oxygen, but develops a pink tint in the glass, which is complementary to and neutralizes the green colour due to ferrous oxide.

Glass is a bad conductor of heat. When boiling water is poured into a glass vessel, the vessel frequently breaks, on account of the unequal expansion of the inner and outer layers. If in the process of glass manufacture a glass vessel is suddenly cooled, the constituent particles are unable to arrange themselves and the vessel remains in a state of extreme tension. The surface of the vessel may be hard, but the vessel is liable to fracture on receiving a trifling shock. M. de la Bastie’s process of “toughening” glass consisted in dipping glass, raised to a temperature slightly below the melting-point, into molten tallow. The surface of the glass was hardened, but the inner layers remained in unstable equilibrium. Directly the crust was pierced the whole mass was shattered into minute fragments. In all branches of glass manufacture the process of “annealing,” i.e. cooling the manufactured objects sufficiently slowly to allow the constituent particles to settle into a condition of equilibrium, is of vital importance. The desired result is obtained either by moving the manufactured goods gradually away from a constant source of heat, or by placing them in a heated kiln and allowing the heat gradually to die out.

The furnaces (fig. 15) employed for melting glass are usually heated with gas on the “Siemens,” or some similar system of regenerative heating. In the United States natural gas is used wherever it is available. In some English works coal is still employed for direct heating with various forms of mechanical stokers. Crude petroleum and a thin tar, resulting from the process of enriching water-gas with petroleum, have been used both with compressed air and with steam with considerable success. Electrical furnaces have not as yet been employed for ordinary glass-making on a commercial scale, but the electrical plants which have been erected for melting and moulding quartz suggest the possibility of electric heating being employed for the manufacture of glass. Many forms of apparatus have been tried for ascertaining the temperature of glass furnaces. It is usually essential that some parts of the apparatus shall be made to acquire a temperature identical with the temperature to be measured. Owing to the physical changes produced in the material exposed prolonged observations of temperature are impossible. In the Féry radiation pyrometer this difficulty is obviated, as the instrument may be placed at a considerable distance from the furnace. The radiation passing out from an opening in the furnace falls upon a concave mirror in a telescope and is focused upon a thermoelectric couple. The hotter the furnace the greater is the rise of temperature of the couple. The electromotive force thus generated is measured by a galvanometer, the scale of which is divided and figured so that the temperature may be directly read. (See Thermometry.)

In dealing with the manufacture of glass it is convenient to group the various branches in the following manner:

Manufactured Glass.

| I. Optical Glass | II. Blown Glass | |

|||||||

| A. Table glass. | B. Tube. Special glasses for thermometers, and other special glasses. |

C. Sheet and |

D. Bottles. | ||||

| III. Mechanically Pressed Glass | |

|||||||

| A. Plate and rolled plate glass. | B. Pressed table glass. | ||||||

I. Optical Glass.—As regards both mode of production and essential properties optical glass differs widely from all other varieties. These differences arise primarily from the fact that glass for optical uses is required in comparatively large and thick pieces, while for most other purposes glass is used in the form of comparatively thin sheets; when, therefore, as a consequence of Dollond’s invention of achromatic telescope objectives in 1757, a demand first arose for optical glass, the industry was unable to furnish suitable material. Flint glass particularly, which appeared quite satisfactory when viewed in small pieces, was found to be so far from homogeneous as to be useless for lens construction. The first step towards overcoming this vital defect in optical glass was taken by P. L. Guinand, towards the end of the 18th century, by introducing the process of stirring the molten glass by means of a cylinder of fireclay. Guinand was induced to migrate from his home in Switzerland to Bavaria, where he worked at the production of homogeneous flint glass, first with Joseph von Utzschneider and then with J. Fraunhofer; the latter ultimately attained considerable success and produced telescope disks up to 28 centimetres (11 in.) diameter. Fraunhofer further initiated the specification of refraction and dispersion in terms of certain lines of the spectrum, and even attempted an investigation of the effect of chemical composition on the relative dispersion produced by glasses in different parts of the spectrum. Guinand’s process was further developed in France by Guinand’s sons and subsequently by Bontemps and E. Feil. In 1848 Bontemps was obliged to leave France for political reasons and came to England, where he initiated the optical glass manufacture at Chance’s glass works near Birmingham, and this firm ultimately attained a considerable reputation in the production of optical glass, especially of large disks for telescope objectives. Efforts at improving optical glass had, however, not been confined to the descendants and successors of Guinand and Fraunhofer. In 1824 the Royal Astronomical Society of London appointed a committee on the subject, the experimental work being carried out by Faraday. Faraday independently recognized the necessity for mechanical agitation of the molten glass in order to ensure homogeneity, and to facilitate his manipulations he worked with dense lead borate glasses which are very fusible, but have proved too unstable for ordinary optical purposes. Later Máes of Clichy (France) exhibited some “zinc crown” glass in small plates of optical quality at the London Exhibition of 1851; and another French glass-maker, Lamy, produced a dense thallium glass in 1867. In 1834 W. V. Harcourt began experiments in glass-making, in which he was subsequently joined by G. G. Stokes. Their object was to pursue the inquiry begun by Fraunhofer as to the effect of chemical composition on the distribution of dispersion. The specific effect of boric acid in this respect was correctly ascertained by Stokes and Harcourt, but they mistook the effect of titanic acid. J. Hopkinson, working at Chance’s glass works, subsequently made an attempt to produce a titanium silicate glass, but nothing further resulted.

The next and most important forward step in the progress of optical glass manufacture was initiated by Ernst Abbe and carried out jointly by him and O. Schott at Jena in Germany. Aided by grants from the Prussian government, these workers systematically investigated the effect of introducing a large number of different chemical substances (oxides) into vitreous fluxes. As a result a whole series of glasses of novel composition and optical properties were produced. A certain number of the most promising of these, from the purely optical point of view, had unfortunately to be abandoned for practical use owing to their chemical instability, and the problem of Fraunhofer, viz. the production of pairs of glasses of widely differing refraction and dispersion, but having a similar distribution of dispersion in the various regions of the spectrum, was not in the first instance solved. On the other hand, while in the older crown and flint glasses the relation between refraction and dispersion had been practically fixed, dispersion and refraction increasing regularly with the density of the glass, in some of the new glasses introduced by Abbe and Schott this relation is altered and a relatively low refractive index is accompanied by a relatively high dispersion, while in others a high refractive index is associated with low dispersive power.

The initiative of Abbe and Schott, which was greatly aided by the resources for scientific investigation available at the Physikalische Reichsanstalt (Imperial Physical Laboratory), led to such important developments that similar work was undertaken in France by the firm of Mantois, the successors of Feil, and somewhat later by Chance in England. The manufacture of the new varieties of glass, originally known as “Jena” glasses, is now carried out extensively and with a considerable degree of commercial success in France, and also to a less extent in England, but none of the other makers of optical glass has as yet contributed to the progress of the industry to anything like the same extent as the Jena firm.

The older optical glasses, now generally known as the “ordinary” crown and flint glasses, are all of the nature of pure silicates, the basic constituents being, in the case of crown glasses, lime and soda or lime and potash, or a mixture of both, and in the case of flint glasses, lead and either (or both) soda and potash. With the exception of the heavier flint (lead) glasses, these can be produced so as to be free both from noticeable colour and from such defects as bubbles, opaque inclusions or “striae,” but extreme care in the choice of all the raw materials and in all the manipulations is required to ensure this result. Further, these glasses, when made from properly proportioned materials, possess a very considerable degree of chemical stability, which is amply sufficient for most optical purposes. The newer glasses, on the other hand, contain a much wider variety of chemical constituents, the most important being the oxides of barium, magnesium, aluminium and zinc, used either with or without the addition of the bases already named in reference to the older glasses, and—among acid bodies—boric anhydride (B2O3) which replaces the silica of the older glasses to a varying extent. It must be admitted that, by the aid of certain of these new constituents, glasses can be produced which, as regards purity of colour, freedom from defects and chemical stability are equal or even superior to the best of the “ordinary” glasses, but it is a remarkable fact that when this is the case the optical properties of the new glass do not fall very widely outside the limits set by the older glasses. On the other hand, the more extreme the optical properties of these new glasses, i.e. the further they depart from the ratio of refractive index to dispersive power found in the older glasses, the greater the difficulty found in obtaining them of either sufficient purity or stability to be of practical use. It is, in fact, admitted that some of the glasses, most useful optically, the dense barium crown glasses, which are so widely used in modern photographic lenses, cannot be produced entirely free either from noticeable colour or from numerous small bubbles, while the chemical nature of these glasses is so sensitive that considerable care is required to protect the surfaces of lenses made from them if serious tarnishing is to be avoided. In practice, however, it is not found that the presence either of a decidedly greenish-yellow colour or of numerous small bubbles interferes at all seriously with the successful use of the lenses for the majority of purposes, so that it is preferable to sacrifice the perfection of the glass in order to secure valuable optical properties.

It is a further striking fact, not unconnected with those just enumerated, that the extreme range of optical properties covered even by the relatively large number of optical glasses now available is in reality very small. The refractive indices of all glasses at present available lie between 1.46 and 1.90, whereas transparent minerals are known having refractive indices lying considerably outside these limits; at least one of these, fluorite (calcium fluoride), is actually used by opticians in the construction of certain lenses, so that probably progress is to be looked for in a considerable widening of the limits of available optical materials; possibly such progress may lie in the direction of the artificial production of large mineral crystals.

The qualities required in optical glasses have already been partly referred to, but may now be summarized:—

1. Transparency and Freedom from Colour.—These qualities can be readily judged by inspection of the glass in pieces of considerable thickness, and they may be quantitatively measured by means of the spectro-photometer.

2. Homogeneity.—The optical desideratum is uniformity of refractive index and dispersive power throughout the mass of the glass. This is probably never completely attained, variations in the sixth significant figure of the refractive index being observed in different parts of single large blocks of the most perfect glass. While such minute and gradual variations are harmless for most optical purposes, sudden variations which generally take the form of striae or veins are fatal defects in all optical glass. In their coarsest forms such striae are readily visible to the unaided eye, but finer ones escape detection unless special means are taken for rendering them visible; such special means conveniently take the form of an apparatus for examining the glass in a beam of parallel light, when the striae scatter the light and appear as either dark or bright lines according to the position of the eye. Plate glass of the usual quality, which appears to be perfectly homogeneous when looked at in the ordinary way, is seen to be a mass of fine striae, when a considerable thickness is examined in parallel light. Plate glass is, nevertheless, considerably used for the cheaper forms of lenses, where the scattering of the light and loss of definition arising from these fine striae is not readily recognized.

Bubbles and enclosures of opaque matter, although more readily observed, do not constitute such serious defects; their presence in a lens, to a moderate extent, does not interfere with its performance (see above).

3. Hardness and Chemical Stability.—These properties contribute to the durability of lenses, and are specially desirable in the outer members of lens combinations which are likely to be subjected to frequent handling or are exposed to the weather. As a general rule, to which, however, there are important exceptions, both these qualities are found to a greater degree, the lower the refractive index of the glass. The chemical stability, i.e. the power of resisting the disintegrating effects of atmospheric moisture and carbonic acid, depends largely upon the quantity of alkalis contained in the glass and their proportion to the lead, lime or barium present, the stability being generally less the higher the proportion of alkali. A high silica-content tends towards both hardness and chemical stability, and this can be further increased by the addition of small proportions of boric acid; in larger quantities, however, the latter constituent produces the opposite effect.

4. Absence of Internal Strain.—Internal strain in glass arises from the unequal contraction of the outer and inner portions of masses of glass during cooling. Processes of annealing, or very gradual cooling, are intended to relieve these strains, but such processes are only completely effective when the cooling, particularly through those ranges of temperature where the glass is just losing the last traces of plasticity, is extremely gradual, a rate measured in hours per degree Centigrade being required. The existence of internal strains in glass can be readily recognized by examination in polarized light, any signs of double refraction indicating the existence of strain. If the glass is very badly annealed, the lenses made from it may fly to pieces during or after manufacture, but apart from such extreme cases the optical effects of internal strain are not readily observed except in large optical apparatus. Very perfectly annealed optical glass is now, however, readily obtainable.

5. Refraction and Dispersion.—The purely optical properties of refraction and dispersion, although of the greatest importance, cannot be dealt with in any detail here; for an account of the optical properties required in glasses for various forms of lenses see the articles Lens and Aberration: II. In Optical Systems. As typical of the range of modern optical glasses Table I. is given, which constituted the list of optical glasses exhibited by Messrs Chance at the Optical Convention in London in 1905. In this table n is the refractive index of the glass for sodium light (the D line of the solar spectrum), while the letters C, F and G′ refer to lines in the hydrogen spectrum by which dispersion is now generally specified. The symbol ν represents the inverse of the dispersive power, its value being (nD−1)/(C−F). The very much longer lists of German and French firms contain only a few types not represented in this table.

| Factory Number. |

Name. | nD. | ν. | Medium Dispersion. C−F. |

Partial and Relative Partial Dispersions. | ||||||

| C−D. |

|

D−F. |

|

F−G′. |

| ||||||

| C. 644 B. 646 A. 605 C. 577 C. 579 A. 569 B. 563 B. 535 A. 490 A. 485 C. 474 B. 466 B. 458 A. 458 A. 432 A. 410 B. 407 A. 370 A. 361 A. 360 A. 337 A. 299 |

Extra Hard Crown Boro-silicate Crown Hard Crown Medium Barium Crown Densest Barium Crown Soft Crown Medium Barium Crown Barium Light Flint Extra Light Flint Extra Light Flint Boro-silicate Flint Barium Light Flint Soda Flint Light Flint Light Flint Light Flint Light Flint Dense Flint Dense Flint Dense Flint Extra Dense Flint Densest Flint |

1.4959 1.5096 1.5175 1.5738 1.6065 1.5152 1.5660 1.5452 1.5316 1.5333 1.5623 1.5833 1.5482 1.5472 1.5610 1.5760 1.5787 1.6118 1.6214 1.6225 1.6469 1.7129 |

64.4 63.3 60.5 57.9 57.9 56.9 56.3 53.5 49.0 48.5 47.4 46.6 45.8 45.8 43.2 41.0 40.7 36.9 36.1 36.0 33.7 29.9 |

.00770 .00803 .00856 .00990 .01046 .00906 .01006 .01020 .01085 .01099 .01187 .01251 .01195 .01196 .01299 .01404 .01420 .01657 .01722 .01729 .01917 .02384 |

.00228 .00236 .00252 .00293 .00308 .00264 .00297 .00298 .00313 .00322 .00343 .00362 .00343 .00348 .00372 .00402 .00404 .00470 .00491 .00493 .00541 .00670 |

.296 .294 .294 .296 .294 .291 .295 .292 .288 .293 .289 .288 .287 .291 .287 .286 .284 .284 .285 .286 .285 .281 |

.00542 .00562 .00604 .00697 .00738 .00642 .00709 .00722 .00772 .00777 .00844 .00889 .00852 .00848 .00927 .01002 .01016 .01187 .01231 .01236 .01376 .01714 |

.704 .700 .706 .704 .705 .708 .704 .701 .711 .707 .711 .711 .713 .709 .713 .713 .715 .716 .715 .715 .720 .789 |

.00431 .00446 .00484 .00552 .00589 .00517 .00576 .00582 .00630 .00640 .00693 .00721 .00690 .00707 .00770 .00840 .00840 .01004 .01046 .01054 .01170 .01661 |

.560 .555 .554 .557 .563 .570 .572 .570 .580 .582 .584 .576 .577 .591 .593 .598 .591 .606 .608 .609 .655 .678 | |

Manufacture of Optical Glass.—In its earlier stages, the process for the production of optical glass closely resembles that used in the production of any other glass of the highest quality. The raw materials are selected with great care to assure chemical purity, but whereas in most glasses the only impurities to be dreaded are those that are either infusible or produce a colouring effect upon the glass, for optical purposes the admixture of other glass-forming bodies than those which are intended to be present must be avoided on account of their effect in modifying the optical constants of the glass. Constancy of composition of the raw materials and their careful and thorough admixture in constant proportions are therefore essential to the production of the required glasses. The materials are generally used in the form either of oxides (lead, zinc, silica, &c.) or of salts readily decomposed by heat, such as the nitrates or carbonates. Fragments of glass of the same composition as that aimed at are generally incorporated to a limited extent with the mixed raw materials to facilitate their fusion. The crucibles or pots used for the production of optical glass very closely resemble those used in the manufacture of flint glass for other purposes; they are “covered” and the molten materials are thus protected from the action of the furnace gases by the interposition of a wall of fireclay, but as crucibles for optical glass are used for only one fusion and are then broken up, they are not made so thick and heavy as those used in flint-glass making, since the latter remain in the furnace for many weeks. On the other hand, the chemical and physical nature of the fireclays used in the manufacture of such crucibles requires careful attention in order to secure the best results. The furnace used for the production of optical glass is generally constructed to take one crucible only, so that the heat of the furnace may be accurately adjusted to the requirements of the particular glass under treatment. These small furnaces are frequently arranged for direct coal firing, but regenerative gas-fired furnaces are also employed. The empty crucible, having first been gradually dried and heated to a bright red heat in a subsidiary furnace, is taken up by means of massive iron tongs and introduced into the previously heated furnace, the temperature of which is then gradually raised. When a suitable temperature for the fusion of the particular glass in question has been attained, the mixture of raw materials is introduced in comparatively small quantities at a time. In this way the crucible is gradually filled with a mass of molten glass, which is, however, full of bubbles of all sizes. These bubbles arise partly from the air enclosed between the particles of raw materials and partly from the gaseous decomposition products of the materials themselves. In the next stage of the process, the glass is raised to a high temperature in order to render it sufficiently fluid to allow of the complete elimination of these bubbles; the actual temperature required varies with the chemical composition of the glass, a bright red heat sufficing for the most fusible glasses, while with others the utmost capacity of the best furnaces is required to attain the necessary temperature. With these latter glasses there is, of course, considerable risk that the partial fusion and consequent contraction of the fireclay of the crucible may result in its destruction and the entire loss of the glass. The stages of the process so far described generally occupy from 36 to 60 hours, and during this time the constant care and watchfulness of those attending the furnace is required. This is still more the case in the next stage. The examination of small test-pieces of the glass withdrawn from the crucible by means of an iron rod having shown that the molten mass is free from bubbles, the stirring process may be begun, the object of this manipulation being to render the glass as homogeneous as possible and to secure the absence of veins or striae in the product. For this purpose a cylinder of fireclay, provided with a square axial hole at the upper end, is heated in a small subsidiary furnace and is then introduced into the molten glass. Into the square axial hole fits the square end of a hooked iron bar which projects several yards beyond the mouth of the furnace; by means of this bar a workman moves the fireclay cylinder about in the glass with a steady circular sweep. Although the weight of the iron bar is carried by a support, such as an overhead chain or a swivel roller, this operation is very laborious and trying, more especially during the earlier stages when the heat radiated from the open mouth of the crucible is intense. The men who manipulate the stirring bars are therefore changed at short intervals, while the bars themselves have also to be changed at somewhat longer intervals, as they rapidly become oxidized, and accumulated scale would tend to fall off them, thus contaminating the glass below. The stirring process is begun when the glass is perfectly fluid at a temperature little short of the highest attained in its fusion, but as the stirring proceeds the glass is allowed to cool gradually and thus becomes more and more viscous until finally the stirring cylinder can scarcely be moved. When the glass has acquired this degree of consistency it is supposed that no fresh movements can occur within its mass, so that if homogeneity has been attained the glass will preserve it permanently. The stirring is therefore discontinued and the clay cylinder is either left embedded in the glass, or by the exercise of considerable force it may be gradually withdrawn. The crucible with the semi-solid glass which it contains is now allowed to cool considerably in the melting furnace, or it may be removed to another slightly heated furnace. When the glass has cooled so far as to become hard and solid, the furnace is hermetically sealed up and allowed to cool very gradually to the ordinary temperature. If the cooling is very gradual—occupying several weeks—it sometimes happens that the entire contents of a large crucible, weighing perhaps 1000 ℔, are found intact as a single mass of glass, but more frequently the mass is found broken up into a number of fragments of various sizes. From the large masses great lenses and mirrors may be produced, while the smaller pieces are used for the production of the disks and slabs of moderate size, in which the optical glass of commerce is usually supplied. In order to allow of the removal of the glass, the cold crucible is broken up and the glass carefully separated from the fragments of fireclay. The pieces of glass are then examined for the detection of the grosser defects, and obviously defective pieces are rejected. As the fractured surfaces of the glass in this condition are unsuitable for delicate examination a good deal of glass that passes this inspection has yet ultimately to be rejected. The next stage in the preparation of the glass is the process of moulding and annealing. Lumps of glass of approximately the right weight are chosen, and are heated to a temperature just sufficient to soften the glass, when the lumps are caused to assume the shape of moulds made of iron or fireclay either by the natural flow of the softened glass under gravity, or by pressure from suitable tools or presses. The glass, now in its approximate form, is placed in a heated chamber where it is allowed to cool very gradually—the minimum time of cooling from a dull red heat being six days, while for “fine annealing” a much longer period is required (see above). At the end of the annealing process the glass issues in the shape of disks or slabs slightly larger than required by the optician in each case. The glass is, however, by no means ready for delivery, since it has yet to be examined with scrupulous care, and all defective pieces must be rejected entirely or at least the defective part must be cut out and the slab remoulded or ground down to a smaller size. For the purpose of rendering this minute examination possible, opposite plane surfaces of the glass are ground approximately flat and polished, the faces to be polished being so chosen as to allow of a view through the greatest possible thickness of glass; thus in slabs the narrow edges are polished.

It will be readily understood from the above account of the process of production that optical glass, relatively to other kinds of glass, is very expensive, the actual price varying from 3s. to 30s. per ℔ in small slabs or disks. The price, however, rapidly increases with the total bulk of perfect glass required in one piece, so that large disks of glass suitable for telescope objectives of wide aperture, or blocks for large prisms, become exceedingly costly. The reason for this high cost is to be found partly in the fact that the yield of optically perfect glass even in large and successful meltings rarely exceeds 20% of the total weight of glass melted. Further, all the subsequent processes of cutting, moulding and annealing become increasingly difficult, owing to the greatly increased risk of breakage arising from either external injury or internal strain, as the dimensions of the individual piece of glass increase. Nevertheless, disks of optical glass, both crown and flint, have been produced up to 39 in. in diameter.

II. Blown Glass. (A) Table-ware and Vases.—The varieties of glass used for the manufacture of table-ware and vases are the potash-lead glass, the soda-lime glass and the potash-lime glass. These glasses may be colourless or coloured. Venetian glass is a soda-lime glass; Bohemian glass is a potash-lime glass. The potash-lead glass, which was first used on a commercial scale in England for the manufacture of table-ware, and which is known as “flint” glass or “crystal,” is also largely used in France, Germany and the United States. Table II. shows the typical composition of these glasses.

| SiO2. | K2O. | PbO. | Na2O. | CaO. | MgO. | Fe2O3 and Al2O3. | |

| Potash-lead (flint) glass Soda-lime (Venetian) glass Potash-lime (Bohemian) glass |

53.17 73.40 71.70 |

13.88 .. 12.70 |

32.95 .. .. |

.. 18.58 2.50 |

.. 5.06 10.30 |

.. .. .. |

.. 2.48 0.90 |

For melting the leadless glasses, open, bowl-shaped crucibles are used, ranging from 12 to 40 in. in diameter. Glass mixtures containing lead are melted in covered, beehive-shaped crucibles holding from 12 to 18 cwt. of glass. They have a hooded opening on one side near the top. This opening serves for the introduction of the glass-mixture, for the removal of the melted glass and as a source of heat for the processes of manipulation.

The Venetian furnaces in the island of Murano are small low structures heated with wood. The heat passes from the melting furnace into the annealing kiln. In Germany, Austria and the United States, gas furnaces are generally used. In England directly-heated coal furnaces are still in common use, which in many cases are stoked by mechanical feeders. There are two systems of annealing. The manufactured goods are either removed gradually from a constant source of heat by means of a train of small iron trucks drawn along a tramway by an endless chain, or are placed in a heated kiln in which the fire is allowed gradually to die out. The second system is especially used for annealing large and heavy objects. The manufacture of table-ware is carried on by small gangs of men and boys. In England each “gang” or “chair” consists of three men and one boy. In works, however, in which most of the goods are moulded, and where less skilled labour is required, the proportion of boy labour is increased. There are generally two shifts of workmen, each shift working six hours, and the work is carried on continuously from Monday morning until Friday morning. Directly work is suspended the glass remaining in the crucibles is ladled into water, drained and dried. It is then mixed with the glass mixture and broken glass (“cullet”), and replaced in the crucibles. The furnaces are driven to a white heat in order to fuse the mixture and expel bubbles of gas and air. Before work begins the temperature is lowered sufficiently to render the glass viscous. In the viscous state a mass of glass can be coiled upon the heated end of an iron rod, and if the rod is hollow can be blown into a hollow bulb. The tools used are extremely primitive—hollow iron blowing-rods, solid rods for holding vessels during manipulation, spring tools, resembling sugar-tongs in shape, with steel or wooden blades for fashioning the viscous glass, callipers, measure-sticks, and a variety of moulds of wood, carbon, cast iron, gun-metal and plaster of Paris (figs. 16 and 17). The most important tool, however, is the bench or “chair” on which the workman sits, which serves as his lathe. He sits between two rigid parallel arms, projecting forwards and backwards and sloping slightly from back to front. Across the arms he balances the iron rod to which the glass bulb adheres, and rolling it backwards and forwards with the fingers of his left hand fashions the glass between the blades of his sugar-tongs tool, grasped in his right hand. The hollow bulb is worked into the shape it is intended to assume, partly by blowing, partly by gravitation, and partly by the workman’s tool. If the blowing iron is held vertically with the bulb uppermost the bulb becomes flattened and shallow, if the bulb is allowed to hang downwards it becomes elongated and reduced in diameter, and if the end of the bulb is pierced and the iron is held horizontally and sharply trundled, as a mop is trundled, the bulb opens out into a flattened disk.

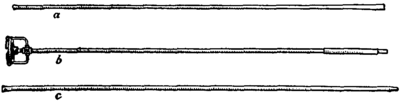

Fig. 16.—Pontils and Blowing Iron.

a, Puntee; b, spring puntee; c, blowing iron.

Fig. 17.—Shaping and Measuring Tools.

| d, “Sugar-tongs” tool with wooden ends. |

f, Pincers, |

| g, Scissors. | |

| e, e, “Sugar-tongs” tools with cutting edges. |

h, Battledore. |

| i,Marking compass. |

During the process of manipulation, whether on the chair or whilst the glass is being reheated, the rod must be constantly and gently trundled to prevent the collapse of the bulb or vessel. Every natural development of the spherical form can be obtained by blowing and fashioning by hand. A non-spherical form can only be produced by blowing the hollow bulb into a mould of the required shape. Moulds are used both for giving shape to vessels and also for impressing patterns on their surface. Although spherical forms can be obtained without the use of moulds, moulds are now largely used for even the simplest kinds of table-ware in order to economize time and skilled labour. In France, Germany and the United States it is rare to find a piece of table-ware which has not received its shape in a mould. The old and the new systems of making a wine-glass illustrate almost all the ordinary processes of glass working. Sufficient glass is first “gathered” on the end of a blowing iron to form the bowl of the wine-glass. The mere act of coiling an exact weight of molten glass round the end of a rod 4 ft. in length requires considerable skill. The mass of glass is rolled on a polished slab of iron, the “marvor,” to solidify it, and it is then slightly hollowed by blowing. Under the old system the form of the bowl is gradually developed by blowing and by shaping the bulb with the sugar-tongs tool. The leg is either pulled out from the substance of the base of the bowl, or from a small lump of glass added to the base. The foot starts as a small independent bulb on a separate blowing iron. One extremity of this bulb is made to adhere to the end of the leg, and the other extremity is broken away from its blowing iron. The fractured end is heated, and by the combined action of heat and centrifugal force opens out into a flat foot. The bowl is now severed from its blowing iron and the unfinished wine-glass is supported by its foot, which is attached to the end of a working rod by a metal clip or by a seal of glass. The fractured edge of the bowl is heated, trimmed with scissors and melted so as to be perfectly smooth and even, and the bowl itself receives its final form from the sugar-tongs tool.

Under the new system the bowl is fashioned by blowing the slightly hollowed mass of glass into a mould. The leg is formed and a small lump of molten glass is attached to its extremity to form the foot. The blowing iron is constantly trundled, and the small lump of glass is squeezed and flattened into the shape of a foot, either between two slabs of wood hinged together, or by pressure against an upright board. The bowl is severed from the blowing iron, and the wine-glass is sent to the annealing oven with a bowl, longer than that of the finished glass, and with a rough fractured edge. When the glass is cold the surplus is removed either by grinding, or by applying heat to a line scratched with a diamond round the bowl. The fractured edge is smoothed by the impact of a gas flame.

In the manufacture of a wine-glass the ductility of glass is illustrated on a small scale by the process of pulling out the leg. It is more strikingly illustrated in the manufacture of glass cane and tube. Cane is produced from a solid mass of molten glass, tube from a mass hollowed by blowing. One workman holds the blowing iron with the mass of glass attached to it, and another fixes an iron rod by means of a seal of glass to the extremity of the mass. The two workmen face each other and walk backwards. The diameter of the cane or tube is regulated by the weight of glass carried, and by the distance covered by the two workmen. It is a curious property of viscous glass that whatever form is given to the mass of glass before it is drawn out is retained by the finished cane or tube, however small its section may be. Owing to this property, tubes or canes can be produced with a square, oblong, oval or triangular section. Exceedingly fine canes of milk-white glass play an important part in the masterpieces produced by the Venetian glass-makers of the 16th century. Vases and drinking cups were produced of extreme lightness, in the walls of which were embedded patterns rivalling lace-work in fineness and intricacy. The canes from which the patterns are formed are either simple or complex. The latter are made by dipping a small mass of molten colourless glass into an iron cup around the inner wall of which short lengths of white cane have been arranged at regular intervals. The canes adhere to the molten glass, and the mass is first twisted and then drawn out into fine cane, which contains white threads arranged in endless spirals. The process can be almost indefinitely repeated and canes formed of extreme complexity. A vase decorated with these simple or complex canes is produced by embedding short lengths of the cane on the surface of a mass of molten glass and blowing and fashioning the mass into the required shape.

Table-ware and vases may be wholly coloured or merely decorated with colour. Touches of colour may be added to vessels in course of manufacture by means of seals of molten glass, applied like sealing-wax; or by causing vessels to wrap themselves round with threads or coils of coloured glass. By the application of a pointed iron hook, while the glass is still ductile, the parallel coils can be distorted into bends, loops or zigzags. The surface of vessels may be spangled with gold or platinum by rolling the hot glass on metallic leaf, or iridescent, by the deposition of metallic tin, or by the corrosion caused by the chemical action of acid fumes. Gilding and enamel decoration are applied to vessels when cold, and fixed by heat.

Cutting and engraving are mechanical processes for producing decorative effects by abrading the surface of the glass when cold. The abrasion is effected by pressing the glass against the edge of wheels, or disks, of hard material revolving on horizontal spindles. The spindles of cutting wheels are driven by steam or electric power. The wheels for making deep cuts are made of iron, and are fed with sand and water. The wheels range in diameter from 18 in. to 3 in. Wheels of carborundum are also used. Wheels of fine sandstone fed with water are used for making slighter cuts and for smoothing the rough surface left by the iron wheels. Polishing is effected by wooden wheels fed with wet pumice-powder and rottenstone and by brushes fed with moistened putty-powder. Patterns are produced by combining straight and curved cuts. Cutting brings out the brilliancy of glass, which is one of its intrinsic qualities. At the end of the 18th century English cut glass was unrivalled for design and beauty. Gradually, however, the process was applied without restraint and the products lost all artistic quality. At the present time cut glass is steadily regaining favour.

Engraving is a process of drawing on glass by means of small copper wheels. The wheels range from 12 in. to 2 in. in diameter, and are fed with a mixture of fine emery and oil. The spindles to which the wheels are attached revolve in a lathe worked by a foot treadle. The true use of engraving is to add interest to vessels by means of coats of arms, crests, monograms, inscriptions and graceful outlines. The improper use of engraving is to hide defective material. There are two other processes of marking patterns on glass, but they possess no artistic value. In the “sandblast” process the surface of the glass is exposed to a stream of sharp sand driven by compressed air. The parts of the surface which are not to be blasted are covered by adhesive paper. In the “etching” process the surface of the glass is etched by the chemical action of hydrofluoric acid, the parts which are not to be attacked being covered with a resinous paint. The glass is first dipped in this protective liquid, and when the paint has set the pattern is scratched through it with a sharp point. The glass is then exposed to the acid.

Glass stoppers are fitted to bottles by grinding. The mouth of the bottle is ground by a revolving iron cone, or mandrel, fed with sand and water and driven by steam. The head of the stopper is fastened in a chuck and the peg is ground to the size of the mouth of the bottle by means of sand and water pressed against the glass by bent strips of thin sheet iron. The mouth of the bottle is then pressed by hand on the peg of the stopper, and the mouth and peg are ground together with a medium of very fine emery and water until an air-tight joint is secured.

The revival in recent years of the craft of glass-blowing in England must be attributed to William Morris and T. G. Jackson, R.A. (Pl. II. figs. 11 and 12). They, at any rate, seem to have been the first to grasp the idea that a wine-glass is not merely a bowl, a stem and a foot, but that, whilst retaining simplicity of form, it may nevertheless possess decorative effect. They, moreover, suggested the introduction for the manufacture of table-glass of a material similar in texture to that used by the Venetians, both colourless and tinted.

The colours previously available for English table-glass were ruby, canary-yellow, emerald-green, dark peacock-green, light peacock-blue, dark purple-blue and a dark purple. About 1870 the “Jackson” table-glass was made in a light, dull green glass. The dull green was followed successively by amber, white opal, blue opal, straw opal, sea-green, horn colour and various pale tints of soda-lime glass, ranging from yellow to blue. Experiments were also tried with a violet-coloured glass, a violet opal, a transparent black and with glasses shading from red to blue, red to amber and blue to green.

In the Paris Exhibition of 1900 surface decoration was the prominent feature of all the exhibits of table-glass. The carved or “cameo” glass, introduced by Thomas Webb of Stourbridge in 1878, had been copied with varying success by glass-makers of all nations. In many specimens there were three or more layers of differently coloured glass, and curious effects of blended colour were obtained by cutting through, or partly through, the different layers. The surface of the glass had usually been treated with hydrofluoric acid so as to have a satin-like gloss. Some vases of this character, shown by Émile Gallé and Daum Frères of Nancy, possessed considerable beauty. The “Favrile” glass of Louis C. Tiffany of New York (Pl. II. fig. 13) owes its effect entirely to surface colour and lustre. The happiest specimens of this glass almost rival the wings of butterflies in the brilliancy of their iridescent colours. The vases of Karl Koepping of Berlin are so fantastic and so fragile that they appear to be creations of the lamp rather than of the furnace. An illustration is also given of some of Powell’s “Whitefriars” glass, shown at the St Louis Exhibition, 1904 (Pl. II. fig. 14). The specimens of “pâte de verre” exhibited by A. L. Dammouse, of Sèvres, in the Musée des Arts décoratifs in Paris, and at the London Franco-British Exhibition in 1908, deserve attention. They have a semi-opaque body with an “egg-shell” surface and are delicately tinted with colour. The shapes are exceedingly simple, but some of the pieces possess great beauty. The material and technique suggest a close relationship to porcelain.

(B) Tube.—The process of making tube has already been described. Although the bore of the thermometer-tube is exceedingly small, it is made in the same way as ordinary tube. The white line of enamel, which is seen in some thermometers behind the bore, is introduced before the mass of glass is pulled out. A flattened cake of viscous glass-enamel is welded on to one side of the mass of glass after it has been hollowed by blowing. The mass, with the enamel attached, is dipped into the crucible and covered with a layer of transparent glass; the whole mass is then pulled out into tube. If the section of the finished tube is to be a triangle, with the enamel and bore at the base, the molten mass is pressed into a V-shaped mould before it is pulled out.

In modern thermometry instruments of extreme accuracy are required, and researches have been made, especially in Germany and France, to ascertain the causes of variability in mercurial thermometers, and how such variability is to be removed or reduced. In all mercurial thermometers there is a slight depression of the ice-point after exposure to high temperatures; it is also not uncommon to find that the readings of two thermometers between the ice- and boiling-points fail to agree at any intermediate temperature, although the ice- and boiling-points of both have been determined together with perfect accuracy, and the intervening spaces have been equally divided. It has been proved that these variations depend to a great extent on the chemical nature of the glass of which the thermometer is made. Special glasses have therefore been produced by Tonnelot in France and at the Jena glass-works in Germany expressly for the manufacture of thermometers for accurate physical measurements; the analyses of these are shown in Table III.

Table III.

| SiO2. | Na2O. | K2O. | CaO. | Al2O2. | MgO. | B2O2. | ZnO. | Depression of Ice-point. | |

| Tonnelot's “Verre dur” Jena glass— XVI.-111 59-111 |

70.96 67.5 72.0 |

12.02 14.0 11.0 |

0.56 .. .. |

14.40 7.0 5.0 |

1.44 2.5 5.0 |

0.40 .. .. |

.. 2.0 12.0 |

.. 7.0 .. |

0.07 0.05 0.02 |

Since the discovery of the Röntgen rays, experiments have been made to ascertain the effects of the different constituents of glass on the transparency of glass to X-rays. The oxides of lead, barium, zinc and antimony are found perceptibly to retard the rays. The glass tubes, therefore, from which the X-ray bulbs are to be fashioned, must not contain any of these oxides, whereas the glass used for making the funnel-shaped shields, which direct the rays upon the patient and at the same time protect the hands of the operator from the action of the rays, must contain a large proportion of lead.

Among the many developments of the Jena Works, not the least important are the glasses made in the form of a tube, from which gas-chimneys, gauge-glasses and chemical apparatus are fashioned, specially adapted to resist sudden changes of temperature. One method is to form the tube of two layers of glass, one being considerably more expansible than the other.

(C) Sheet and Crown-glass.—Sheet-glass is almost wholly a soda-lime-silicate glass, containing only small quantities of iron, alumina and other impurities. The raw materials used in this manufacture are chosen with considerable care, since the requirements as to the colour of the product are somewhat stringent. The materials ordinarily employed are the following: sand, of good quality, uniform in grain and free from any notable quantity of iron oxide; carbonate of lime, generally in the form of a pure variety of powdered limestone; and sulphate of soda. A certain proportion of soda ash (carbonate of soda) is also used in some works in sheet-glass mixtures, while “decolorizers” (substances intended to remove or reduce the colour of the glass) are also sometimes added, those most generally used being manganese dioxide and arsenic. Another essential ingredient of all glass mixtures containing sulphate of soda is some form of carbon, which is added either as coke, charcoal or anthracite coal; the carbon so introduced aids the reducing substances contained in the atmosphere of the furnace in bringing about the reduction of the sulphate of soda to a condition in which it combines more readily with the silicic acid of the sand. The proportions in which these ingredients are mixed vary according to the exact quality of glass required and with the form and temperature of the melting furnace employed. A good quality of sheet-glass should show, on analysis, a composition approximating to the following: silica (SiO2), 72%; lime (CaO), 13%; soda (Na2O), 14%; and iron and alumina (Fe2O3, Al2O3), 1%. The actual composition, however, of a mixture that will give a glass of this composition cannot be directly calculated from these figures and the known composition of the raw materials, owing to the fact that considerable losses, particularly of alkali, occur during melting.

The fusion of sheet-glass is now generally carried out in gas-fired regenerative tank furnaces. The glass in process of fusion is contained in a basin or tank built up of large blocks of fire-clay and is heated by one or more powerful gas flames which enter the upper part of the furnace chamber through suitable apertures or “ports.” In Europe the gas burnt in these furnaces is derived from special gas-producers, while in some parts of America natural gas is utilized. With producer gas it is necessary to pre-heat both the gas and the air which is supplied for its combustion by passing both through heated regenerators (for an account of the principles of the regenerative furnace see article Furnace). In many respects the glass-melting tank resembles the open-hearth steel furnace, but there are certain interesting differences. Thus the dimensions of the largest glass tanks greatly exceed those of the largest steel furnaces; glass furnaces containing up to 250 tons of molten glass have been successfully operated, and owing to the relatively low density of glass this involves very large dimensions. The temperature required in the fusion of sheet-glass and of other glasses produced in tank furnaces is much lower than that attained in steel furnaces, and it is consequently possible to work glass-tanks continuously for many months together; on the other hand, glass is not readily freed from foreign bodies that may become admixed with it, so that the absence of detachable particles is much more essential in glass than in steel melting. Finally, fluid steel can be run or poured off, since it is perfectly fluid, while glass cannot be thus treated, but is withdrawn from the furnace by means of either a ladle or a gatherer’s pipe, and the temperature required for this purpose is much lower than that at which the glass is melted. In a sheet-glass tank there is therefore a gradient of temperature and a continuous passage of material from the hotter end of the furnace where the raw materials are introduced to the cooler end where the glass, free from bubbles and raw material, is withdrawn by the gatherers. For the purpose of the removal of the glass, the cooler end of the furnace is provided with a number of suitable openings, provided with movable covers or shades. The “gatherer” approaches one of these openings, removes the shade and introduces his previously heated “pipe.” This instrument is an iron tube, some 5 ft. long, provided at one end with an enlarged butt and at the other with a wooden covering acting as handle and mouthpiece. The gatherer dips the butt of the pipe into the molten “metal” and withdraws upon it a small ball of viscous glass, which he allows to cool in the air while constantly rotating it so as to keep the mass as nearly spherical in shape as he can. When the first ball or “gathering” has cooled sufficiently, the whole is again dipped into the molten glass and a further layer adheres to the pipe-end, thus forming a larger ball. This process is repeated, with slight modifications, until the gathering is of the proper size and weight to yield the sheet which is to be blown. When this is the case the gathering is carried to a block or half-open mould in which it is rolled and blown until it acquires, roughly, the shape of a hemisphere, the flat side being towards the pipe and the convexity away from it; the diameter of this hemisphere is so regulated as to be approximately that of the cylinder which is next to be formed of the viscous mass. From the hemispherical shape the mass of glass is now gradually blown into the form of a short cylinder, and then the pipe with the adherent mass of glass is handed over to the blower proper. This workman stands upon a platform in front of special furnaces which, from their shape and purpose, are called “blowing holes.” The blower repeatedly heats the lower part of the mass of glass and keeps it distended by blowing while he swings it over a deep trench which is provided next to his working platform. In this way the glass is extended into the form of a long cylinder closed at the lower end. The size of cylinder which can be produced in this way depends chiefly upon the dimensions of the working platform and the weight which a man is able to handle freely. The lower end of the cylinder is opened, in the case of small and thin cylinders, by the blower holding his thumb over the mouthpiece of the pipe and simultaneously warming the end of the cylinder in the furnace, the expansion of the imprisoned air and the softening of the glass causing the end of the cylinder to burst open. The blower then heats the end of the cylinder again and rapidly spins the pipe about its axis; the centrifugal effect is sufficient to spread the soft glass at the end to a radius equal to that of the rest of the cylinder. In the case of large and thick cylinders, however, another process of opening the ends is generally employed: an assistant attaches a small lump of hot glass to the domed end, and the heat of this added glass softens the cylinder sufficiently to enable the assistant to cut the end open with a pair of shears; subsequently the open end is spun out to the diameter of the whole as described above. The finished cylinder is next carried to a rack and the pipe detached from it by applying a cold iron to the neck of thick hot glass which connects pipe-butt and cylinder, the neck cracking at the touch. Next, the rest of the connecting neck is detached from the cylinder by the application of a heated iron to the chilled glass. This leaves a cylinder with roughly parallel ends; these ends are cut by the use of a diamond applied internally and then the cylinder is split longitudinally by the same means. The split cylinder is passed to the flattening furnace, where it is exposed to a red heat, sufficient to soften the glass; when soft the cylinder is laid upon a smooth flat slab and flattened down upon it by the careful application of pressure with some form of rubbing implement, which frequently takes the form of a block of charred wood. When flattened, the sheet is moved away from the working opening of the furnace, and pushed to a system of movable grids, by means of which it is slowly moved along a tunnel, away from a source of heat nearly equal in temperature to that of the flattening chamber. The glass thus cools gradually as it passes down the tunnel and is thereby adequately annealed.

The process of sheet-glass manufacture described above is typical of that in use in a large number of works, but many modifications are to be found, particularly in the furnaces in which the glass is melted. In some works, the older method of melting the glass in large pots or crucibles is still adhered to, although the old-fashioned coal-fired furnaces have nearly everywhere given place to the use of producer gas and regenerators. For the production of coloured sheet-glass, however, the employment of pot furnaces is still almost universal, probably because the quantities of glass required of any one tint are insufficient to employ even a small tank furnace continuously; the exact control of the colour is also more readily attained with the smaller bulk of glass which has to be dealt with in pots. The general nature of the colouring ingredients employed, and the colour effects produced by them, have already been mentioned. In coloured sheet-glass, two distinct kinds are to be recognized; in one kind the colouring matter is contained in the body of the glass itself, while in the other the coloured sheet consists of ordinary white glass covered upon one side with a thin coating of intensely coloured glass. The latter kind is known as “flashed,” and is universally employed in the case of colouring matters whose effect is so intense that in any usual thickness of glass they would cause almost entire opacity. Flashed glass is produced by taking either the first or the last gathering in the production of a cylinder out of a crucible containing the coloured “metal,” the other gatherings being taken out of ordinary white sheet-glass. It is important that the thermal expansion of the two materials which are thus incorporated should be nearly alike, as otherwise warping of the finished sheet is liable to result.

Mechanical Processes for the Production of Sheet-glass.—The complicated and indirect process of sheet-glass manufacture has led to numerous inventions aiming at a direct method of production by more or less mechanical means. All the earlier attempts in this direction failed on account of the difficulty of bringing the glass to the machines without introducing air-bells, which are always formed in molten glass when it is ladled or poured from one vessel into another. More modern inventors have therefore adopted the plan of drawing the glass direct from the furnace. In an American process the glass is drawn direct from the molten mass in the tank in a cylindrical form by means of an iron ring previously immersed in the glass, and is kept in shape by means of special devices for cooling it rapidly as it leaves the molten bath. In this process, however, the entire operations of splitting and flattening are retained, and although the mechanical process is said to be in successful commercial operation, it has not as yet made itself felt as a formidable rival to hand-made sheet-glass. An effort at a more direct mechanical process is embodied in the inventions of Foucault which are at present being developed in Germany and Belgium; in this process the glass is drawn from the molten bath in the shape of flat sheets, by the aid of a bar of iron, previously immersed in the glass, the glass receiving its form by being drawn through slots in large fire-bricks, and being kept in shape by rapid chilling produced by the action of air-blasts. The mechanical operation is quite successful for thick sheets, but it is not as yet available for the thinner sheets required for the ordinary purposes of sheet-glass, since with these excessive breakage occurs, while the sheets generally show grooves or lines derived from small irregularities of the drawing orifice. For the production of thick sheets which are subsequently to be polished the process may thus claim considerable success, but it is not as yet possible to produce satisfactory sheet-glass by such means.

Crown-glass has at the present day almost disappeared from the market, and it has been superseded by sheet-glass, the more modern processes described above being capable of producing much larger sheets of glass, free from the knob or “bullion” which may still be seen in old crown-glass windows. For a few isolated purposes, however, it is desirable to use a glass which has not been touched upon either surface and thus preserves the lustre of its “fire polish” undiminished; this can be attained in crown-glass but not in sheet, since one side of the latter is always more or less marked by the rubber used in the process of flattening. One of the few uses of crown-glass of this kind is the glass slides upon which microscopic specimens are mounted, as well as the thin glass slips with which such preparations are covered. A full account of the process of blowing crown-glass will be found in all older books and articles on the subject, so that it need only be mentioned here that the glass, instead of being blown into a cylinder, is blown into a flattened sphere, which is caused to burst at the point opposite the pipe and is then, by the rapid spinning of the glass in front of a very hot furnace-opening, caused to expand into a flat disk of large diameter. This only requires to be annealed and is then ready for cutting up, but the lump of glass by which the original globe was attached to the pipe remains as the bullion in the centre of the disk of glass.

Coloured Glass for Mosaic Windows.—The production of coloured glass for “mosaic” windows has become a separate branch of glass-making. Charles Winston, after prolonged study of the coloured windows of the 13th, 14th and 15th centuries, convinced himself that no approach to the colour effect of these windows could be made with glass which is thin and even in section, homogeneous in texture, and made and coloured with highly refined materials. To obtain the effect it was necessary to reproduce as far as possible the conditions under which the early craftsmen worked, and to create scientifically glass which is impure in colour, irregular in section, and non-homogeneous in texture. The glass is made in cylinders and in “crowns” or circles. The cylinders measure about 14 in. in length by 8 in. in diameter, and vary in thickness from 18 to 38 in. The crowns are about 15 in. in diameter, and vary in thickness from 18 to 12 in., the centre being the thickest. These cylinders and crowns may be either solid colour or flashed. Great variety of colour may be obtained by flashing one colour upon another, such as blue on green, and ruby on blue, green or yellow.

E. J. Prior has introduced an ingenious method of making small oblong and square sheets of coloured glass, which are thick in the centre and taper towards the edges, and which have one surface slightly roughened and one brilliantly polished. Glass is blown into an oblong box-shaped iron mould, about 12 in. in depth and 6 in. across. A hollow rectangular bottle is formed, the base and sides of which are converted into sheets. The outer surface of these sheets is slightly roughened by contact with the iron mould.

(D) Bottles and mechanically blown Glass.—The manufacture

of bottles has become an industry of vast proportions. The

demand constantly increases, and, owing to constant improvements

in material in the moulds and in the methods of working,

the supply fully keeps pace with the demand. Except for

making bottles of special colours, gas-heated tank furnaces are

in general use. Melting and working are carried on continuously.

The essential qualities of a bottle are strength and power to resist

chemical corrosion. The materials are selected with a view to

secure these qualities. For the highest quality of bottles, which

are practically colourless, sand, limestone and sulphate and

carbonate of soda are used. The following is a typical analysis

of high quality bottle-glass: SiO2, 69.15%; Na2O, 13.00%;

CaO, 15.00%; Al2O3, 2.20%; and Fe2O3, 0.65%. For the

commoner grades of dark-coloured bottles the glass mixture

Fig. 18.—Tool for moulding the inside and outside of the neck of a bottle.

C, Bottle.

A, Conical piece of

iron to form the

inside of the

neck.

B, B, Shaped pieces

of iron, which can

be pressed upon

the outside of

the neck by the

spring-handle H.is cheapened by substituting common salt for part of the sulphate

of soda, and by the addition of felspar, granite, granulite,

furnace slag and other substances fusible at a high temperature.

Bottle moulds are made of cast iron, either in two pieces, hinged

together at the base or at one side, or in three pieces, one

forming the body and two pieces forming the neck.

A bottle gang or “shop” consists of five persons. The “gatherer” gathers the glass from the tank furnace on the end of the blowing-iron, rolls it on a slab of iron or stone, slightly expands the glass by blowing, and hands the blowing iron and glass to the “blower.” The blower places the glass in the mould, closes the mould by pressing a lever with his foot, and either blows down the blowing iron or attaches it to a tube connected with a supply of compressed air. When the air has forced the glass to take the form of the mould, the mould is opened and the blower gives the blowing iron with the bottle attached to it to the “wetter off.” The wetter off touches the top of the neck of the bottle with a moistened piece of iron and by tapping the blowing iron detaches the bottle and drops it into a wooden trough. He then grips the body of the bottle with a four-pronged clip, attached to an iron rod, and passes it to the “bottle maker.” The bottle maker heats the fractured neck of the bottle, binds a band of molten glass round the end of it and simultaneously shapes the inside and the outside of the neck by using the tool shown in fig. 18. The finished bottle is taken by the “taker in” to the annealing furnace. The bottles are stacked in iron trucks, which, when full, are moved slowly away from a constant source of heat.

The processes of manipulation which have been described, although in practice they are very rapidly performed, are destined to be replaced by the automatic working of a machine. Bottle-making machines, based on Ashley’s original patent, are already being largely used. They ensure absolute regularity in form and save both time and labour. A bottle-making machine combines the process of pressing with a plunger with that of blowing by compressed air. The neck of the bottle is first formed by the plunger, and the body is subsequently blown by compressed air admitted through the plunger. A sufficient weight of molten glass to form a bottle is gathered and placed in a funnel-shaped vessel which serves as a measure, and gives access to the mould which shapes the outside of the neck. A plunger is forced upwards into the glass in the neck-mould and forms the neck. The funnel is removed, and the plunger, neck-mould and the mass of molten glass attached to the neck are inverted. A bottle mould rises and envelops the mass of molten glass. Compressed air admitted through the plunger forces the molten glass to take the form of the bottle mould and completes the bottle.

In the case of the machine patented by Michael Owens of Toledo, U.S.A., for making tumblers, lamp-chimneys, and other goods of similar character, the manual operations required are (1) gathering the molten glass at the end of a blowing iron; (2) placing the blowing iron with the glass attached to it in the machine; (3) removing the blowing iron with the blown vessel attached. Each machine (fig. 19) consists of a revolving table carrying five or six moulds. The moulds are opened and closed by cams actuated by compressed air. As soon as a blowing iron is in connexion with an air jet, the sections of the mould close upon the molten glass, and the compressed air forces the glass to take the form of the mould. After removal from the machine, the tumbler is severed from the blowing iron, and its fractured edge is trimmed.

Compressed air or steam is also used for fashioning very large vessels, baths, dishes and reservoirs by the “Sievert” process. Molten glass is spread upon a large iron plate of the required shape and dimensions. The flattened mass of glass is held by a rim, connected to the edge of the plate. The plate with the glass attached to it is inverted, and compressed air or steam is introduced through openings in the plate. The mass of glass, yielding to its own weight and the pressure of air or steam, sinks downwards and adapts itself to any mould or receptacle beneath it.

The processes employed in the manufacture of the glass bulbs for incandescent electric lamps, are similar to the old-fashioned processes of bottle making. The mould is in two pieces hinged together; it is heated and the inner surface is rubbed over with finely powdered plumbago. When the glass is being blown in the mould the blowing iron is twisted round and round so that the finished bulb may not be marked by the joint of the mould.

III. Mechanically Pressed Glass. (A) Plate-glass.—The glass popularly known as “plate-glass” is made by casting and rolling. The following are typical analyses:

| SiO2. | CaO. | Na2O. | Al2O3. | Fe2O3. | |

| French English |

71.80 70.64 |

15.70 16.27 |

11.10 11.47 |

1.26 0.70 |

0.14% 0.49% |

The raw materials for the production of plate-glass are chosen with great care so as to secure a product as free from colour as possible, since the relatively great thickness of the sheets would render even a faint tint conspicuous. The substances employed are the same as those used for the manufacture of sheet-glass, viz. pure sand, a pure form of carbonate of lime, and sulphate of soda, with the addition of a suitable proportion of carbon in the form of coke, charcoal or anthracite coal.