where l is the span in feet and r is the ratio of span to depth of girder at centre. Taking K for steel girders as 7200 to 9000,

| Limiting Span in Ft. | |

| r = 12 | l = 600 to 750 |

| r = 10 | l = 720 to 900 |

| r = 8 | l = 900 to 1120 |

The practical limit of span would be less than this. Professor Claxton Fidier (Treatise on Bridge Construction, 1887) has made a very careful theoretical analysis of the weights of bridges of different types, and has obtained the following values for the limiting spans. For parallel girders when r = 10, the limiting span is 1070 ft. For parabolic or bowstring girders, when r = 8, the limiting span is 1280 ft. For flexible suspension bridges with wrought iron link chains, and dip = 1/10th of the span, the limiting span is 2800 ft. For stiffened suspension bridges with wire cables, if the dip is 1/10th of the span the limiting span is 2700 to 3600 ft., and if the dip is 1/8th of the span, 3250 to 4250 ft., according to the factor of safety allowed.

|

Fig. 57. |

31. Braced Girders.—A frame is a rigid structure composed of straight struts and ties. The struts and ties are called bracing bars. The frame as a whole may be subject to a bending moment, but each member is simply extended or compressed so that the total stress on a given member is the same at all its cross sections, while the intensity of stress is uniform for all the parts of any one cross section. This result must follow in any frame, the members of which are so connected that the joints offer little or no resistance to change in the relative angular position of the members. Thus if the members are pinned together, the joint consisting of a single circular pin, the centre of which lies in the axis of the piece, it is clear that the direction of the only stress which can be transmitted from pin to pin will coincide with this axis. The axis becomes, therefore, a line of resistance, and in reasoning of the stresses on frames we may treat the frame as consisting of simple straight lines from joint to joint. It is found in practice that the stresses on the several members do not differ sensibly whether these members are pinned together with a single pin or more rigidly jointed by several bolts or rivets. Frames are much used as girders, and they also give useful designs for suspension and arched bridges. A frame used to support a weight is often called a truss; the stresses on the various members of a truss can be computed for any given load with greater accuracy than the intensity of stress on the various parts of a continuous structure such as a tubular girder, or the rib of an arch. Many assumptions are made in treating of the flexure of a continuous structure which are not strictly true; no assumption is made in determining the stresses on a frame except that the joints are flexible, and that the frame shall be so stiff as not sensibly to alter in form under the load. Frames used as bridge trusses should never be designed so that the elongation or compression of one member can elongate or compress any other member. An example will serve to make the meaning of this limitation clearer. Let a frame consist of the five members AB, BD, DC, CA, CB (fig. 57), jointed at the points A, B, C and D, and all capable of resisting tension and compression. This frame will be rigid, i.e. it cannot be distorted without causing an alteration in the length of one or more of the members; but if from a change of temperature or any other cause one or all of the members change their length, this will not produce a stress on any member, but will merely cause a change in the form of the frame. Such a frame as this cannot be self-strained. A workman, for instance, cannot produce a stress on one member by making some other member of a wrong length. Any error of this kind will merely affect the form of the frame; if, however, another member be introduced between A and D, then if BC be shortened AD will be strained so as to extend it, and the four other members will be compressed; if CB is lengthened AD will thereby be compressed, and the four other members extended; if the workman does not make CB and AD of exactly the right length they and all the members will be permanently strained. These stresses will be unknown quantities, which the designer cannot take into account, and such a combination should if possible be avoided. A frame of this second type is said to have one redundant member.

32. Types of Braced Girder Bridges.—Figs. 58, 59 and 60 show an independent girder, a cantilever, and a cantilever and suspended girder bridge.

In a three-span bridge continuous girders are lighter than discontinuous ones by about 45% for the dead load and 15% for the live load, if no allowance is made for ambiguity due to uncertainty as to the level of the supports. The cantilever and suspended girder types are as economical and free from uncertainty as to the stresses. In long-span bridges the cantilever system permits erection by building out, which is economical and sometimes necessary. It is, however, unstable unless rigidly fixed at the piers. In the Forth bridge stability is obtained partly by the great excess of dead over live load, partly by the great width of the river piers. The majority of bridges not of great span have girders with parallel booms. This involves the fewest difficulties of workmanship and perhaps permits the closest approximation of actual to theoretical dimensions of the parts. In spans over 200 ft. it is economical to have one horizontal boom and one polygonal (approximately parabolic) boom. The hog-backed girder is a compromise between the two types, avoiding some difficulties of construction near the ends of the girder.

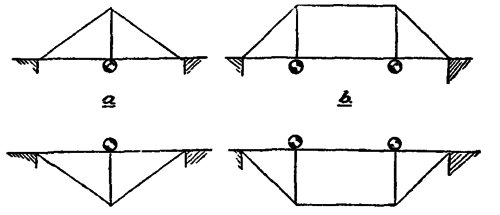

Most braced girders may be considered as built up of two simple forms of truss, the king-post truss (fig. 61, a), or the queen-post truss (fig. 61, b). These may be used in either the upright or the inverted position. A multiple truss consists of a number of simple trusses, e.g. Bollman truss. Some timber bridges consist of queen-post trusses in the upright position, as shown diagrammatically in fig. 62, where the circles indicate points at which the flooring girders transmit load to the main girders. Compound trusses consist of simple trusses used as primary, secondary and tertiary trusses, the secondary supported on the primary, and the tertiary on the secondary. Thus, the Fink truss consists of king-post trusses; the Pratt truss (fig. 63) and the Whipple truss (fig. 64) of queen-post trusses alternately upright and inverted.

A combination bridge is built partly of timber, partly of steel, the compression members being generally of timber and the tension members of steel. On the Pacific coast, where excellent timber is obtainable and steel works are distant, combination bridges are still largely used (Ottewell, Trans. Am. Soc. C.E. xxvii. p. 467). The combination bridge at Roseburgh, Oregon, is a cantilever bridge.