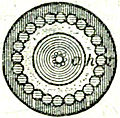

—is shown in fig. 1. It consists of two distinct cups (c, C), which are moulded and fired separately, and afterwards cemented together. The double cup gives great security against loss of insulation due to cracks extending through the insulator, and also gives a high surface insulation. An iron bolt (6) cemented into the centre of the inner cup is used for fixing the insulator to the pole or bracket.

Fig. 1.—Varley's Double Cup Insulator, one-fourth full size.

Underground lines. In the underground system the main line generally consists of a copper wire, or a thin strand of copper wires, covered with a continuous coating of gutta percha, india-rubber, or some equivalent insulating substance, served with tarred tape and enclosed in earthenware, iron, or lead pipes laid below the surface of the ground. This system is largely used for street and tunnel work, and to a considerable extent, especially in Germany, for ordinary lines. Each tube generally contains a number of wires, which are either laid up into a cable and covered with a serving of tarred tape or hemp before being drawn into the tube, or—as is more commonly the case in the United Kingdom—simply laid together in a parallel group and tied at intervals with binders, which are removed as the wires are drawn into the tube. On some long underground lines in Germany the insulated wires are laid up into a cable, served with jute or hemp, and sheathed with a continuous covering of iron wires, precisely similar to the submarine cables described below. The cable is laid in a deep trench and coated with bitumen. This form of cable is easily laid, and if properly manufactured is likely to be very durable.

Submarine cables.Submarine Cables.—A submarine cable (figs. 2-4), as usually manufactured at present, consists of a core a in the centre of which is a strand of copper wires varying in weight for different cables between 70 and 400 lb to the mile.

Fig. 3. |

Fig. 4. |

Figs. 2-4—Sections of three types of submarine cables, full size. Fig. 2.—Type of shore end. Fig. 3.—Intermediate type. Fig. 4.—Deep sea type.

The stranded form was suggested by Prof. W. Thomson at a meeting of the Philosophical Society of Glasgow in 1854, because its greater flexibility renders it less likely to damage the insulating envelope the manipulation of the cable. The central conductor is covered with several continuous coatings of gutta percha, the total weight of which also varies between 70 and 400 lb to the mile. With a light core the weight of the gutta percha generally exceeds that of the copper, while in some heavy cores the copper is heavier. The different coatings of gutta percha and of the conductor are usually separated by a thin coating of Chatterton's compound (a mixture of gutta percha, resin, and Stockholm tar), in order to make them adhere firmly together. This practice has recently been departed from by Messrs Siemens Brothers, who have succeeded by an improved process of manufacture in getting perfect adhesion without the use of the compound. The core is served with a thick coating of wet jute, yarn, or hemp (h), forming a soft bed for the sheath, which consists of soft iron, or of homogeneous iron, wires of the best quality. The sheathing wires are usually covered with one or two servings of tarred canvas tape (t), or of tarred hemp, laid on alternately with coatings of a mixture of asphaltum and tar. The weight of the iron sheath varies greatly according to the depth of the water, the nature of the sea bottom, the prevalence of currents, and so on. Fig. 2 shows the intermediate type again sheathed with a heavy armour to resist wear in the shallow water near shore. In many cases a still heavier type is used for the first mile or two from shore, and several intermediate types are often introduced, tapering gradually to the thin deep-water type. Captain S. Trot and Mr F. A. Hamilton have proposed[1] to abandon the iron sheath and substitute a strong double serving of hemp, laid on in such a way as to prevent twisting when the cable is under tension. This suggestion, which is a revival with some modifications of an old idea, is, however, still in the experimental stage.

We will now describe very briefly a few of the most important processes in the manufacture and submergence of submarine cables.

Their manufacture.In manufacturing a cable (fig. 5) the copper strand is passed through a vessel A containing melted Chatterton's compound, then through the cylinder C, in which a quantity of gutta percha, purified by repeated washing in hot water, by mastication, and by filtering through wire-gauze filters, is kept warm by a steam-jacket.

As the wire is pulled through, a coating of gutta percha, the thickness of which is regulated by the die D, is pressed out of the cylinder by applying the requisite pressure to the piston P. The newly coated wire is passed through a long trough T, containing cold water, until it is sufficiently cold to allow it to be safely wound on a bob bin B. This operation completed, the wire is wound from the bobbin B on to another, and at the same time carefully examined for air-holes or other flaws, all of which are eliminated. The coated wire is treated in the same way as the copper strand, the die D, or another of the same size, being placed at the back of the cylinder and a larger one substituted at the front. A second coating is then laid on, and after it passes through a similar process of examination a third coating is applied, and so on until the requisite number is completed. The finished core changes rapidly in its electric qualities at first, and is generally kept for a stated interval of time before being subjected to the specified tests. It is then placed in a tank of water and kept at a certain fixed temperature, usually 75 Fahr., until it assumes approximately a constant electrical state. Its conductor and dielectric resistance and its electrostatic capacity are then measured. These tests are generally repeated at another temperature, say 50 Fahr., for the purpose of obtaining at the same time greater certainty of the soundness of the core and the rate of variation of the conductor and dielectric resistances with temperature. Should these tests prove satisfactory the core is served with jute yarn, coiled in water tight tanks, and surrounded with salt water. The insulation is again tested, and if no fault is discovered the served core is passed through the sheathing machine, and the iron sheath and the outer covering are laid on. As the cable is sheathed it is stored in large water-tight tanks and kept at a nearly uniform temperature by means of water.

Submersion.The cable is now transferred to a cable ship, provided with water-tight tanks similar to those used in the factory for storing it. The tanks are nearly cylindrical in form and have a truncated cone

- ↑ Journ. Soc. Telegr. Eng., vol. xii. p. 495.