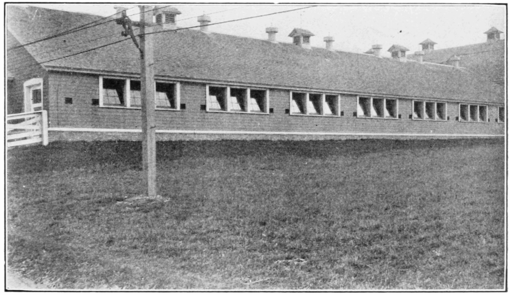

of tuberculosis even in initial stages. The stables are constructed with cement floors, with plenty of windows to admit light, and with effective designs for ventilation. Accompanying photographs, taken in model dairies, will illustrate the points under discussion. Photograph 1 shows one side of a sanitary barn with properly constructed windows, which open from the top and admit fresh air, and a carrier to remove the manure. A carrier of similar nature is used for bringing in the food, as shown in photograph 2. By the use of these carriers the handling of food and refuse is reduced to a minimum, and the raising of dust largely avoided. Photograph 3 shows stanchions of approved style, which allow the animals to be comfortable without being cumbersome. They are made of iron pipe, painted and easily kept clean. Photograph 4 shows the center aisle. The cows face each other to encourage cheerfulness. The mangers are also made of cement. Photograph 5 shows washstands, which should be present in all cow barns. The milkers wash their hands frequently so that the dirt from their hands is not mixed with the milk. The milkers should wear clean white suits, as is shown in photographs 6 and 7. The outlets of foul air and the tilting windows are shown to advantage in photograph 8.

In sanitary dairies the milk is transported to a special room in which it is cooled and bottled. In photograph 9 a cooling apparatus is seen above the collecting tank and on the left-hand side of the same picture is seen a machine which places the pulp caps on bottles.

Market milk contains hundreds of thousands of bacteria per cubic centimeter, sometimes even millions. When only such milk is obtainable it should be pasteurized. Pasteurization is a process by which milk is heated to 140° F. for thirty minutes. This treatment kills about