�IN this day and age of enlightenment it is impossible to believe that there is any- body who doesn't know everything about saws — plain, ordinary carpenter saws. A saw is the simplest thing in the world. It is made of flexible steel with little nicks along the edge that tear a narrow slot in a piece of wood. Of course! But do you know the real difference between a rip-

��Discovering the Well Known Saw

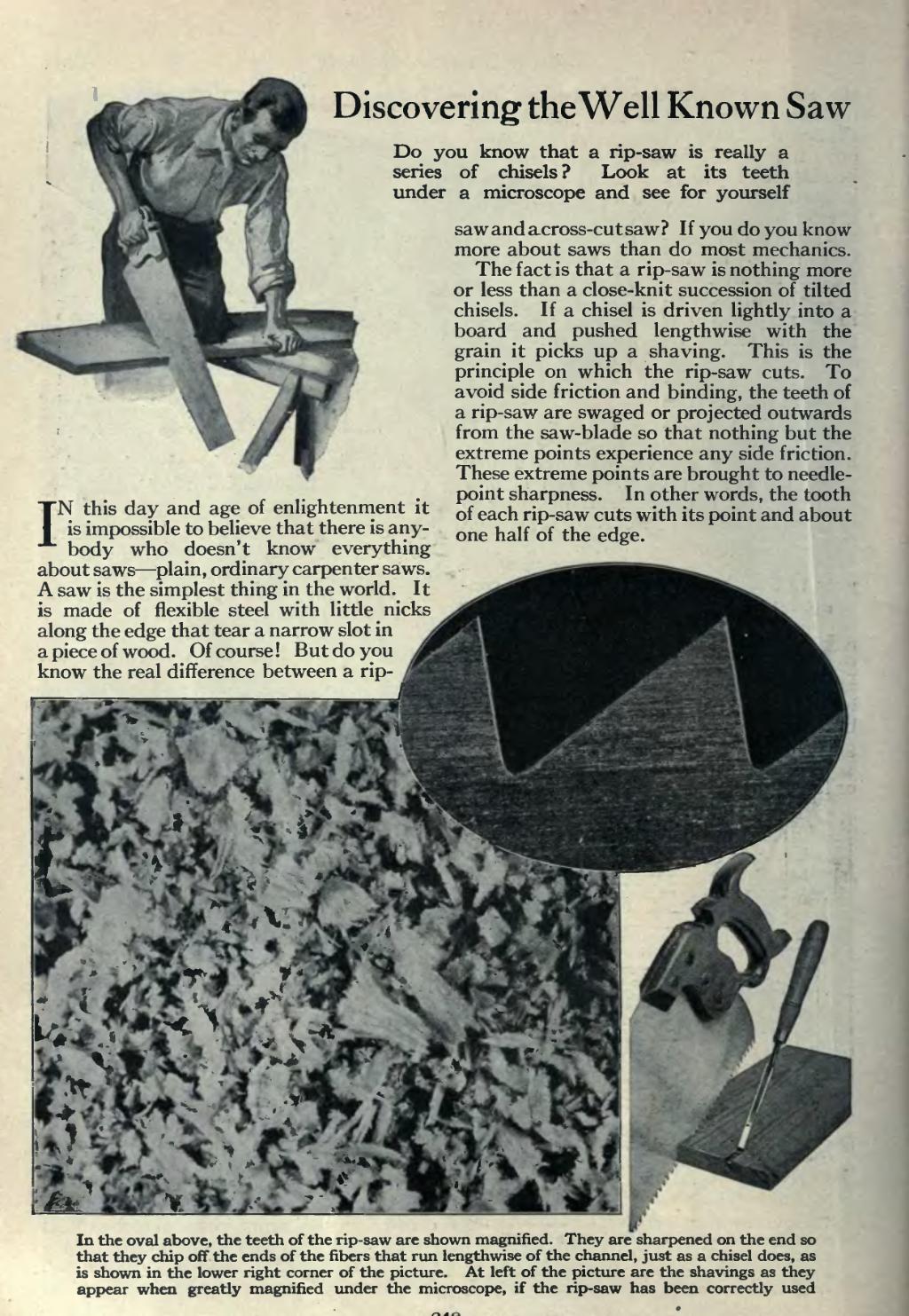

��Do you know that a rip-saw is really a series of chisels ? Look at its teeth under a microscope and see for yourself

saw and across-cut saw? If you do you know more about saws than do most mechanics. The fact is that a rip-saw is nothing more or less than a close-knit succession of tilted chisels. If a chisel is driven lightly into a board and pushed lengthwise with the grain it picks up a shaving. This is the principle on which the rip-saw cuts. To avoid side friction and binding, the teeth of a rip-saw are swaged or projected outwards from the saw-blade so that nothing but the extreme points experience any side friction. These extreme points are brought to needle- point sharpness. In other words, the tooth of each rip-saw cuts with its point and about one half of the edge.

��� ��� ���In the oval above, the teeth of the rip-saw are shown magnified. They are sharpened on the end so that they chip off the ends of the fibers that run lengthwise of the channel, just as a chisel does, as is shown in die lower right comer of the picture. At left of the picture are the shavings as they appear when greatly magnified under the microscope, if the rip-saw has been correctly used

�� �