Popular Science Monthly/Volume 50/January 1897/Disinfection at Quarantine

| DISINFECTION AT QUARANTINE. |

A FLOATING DISINFECTING PLANT.

By M. E. WARD.

THE necessity of thorough precautionary quarantine methods is generally accepted. The adoption and adaptation of methods and apparatus to keep pace with the knowledge that scientific research has placed at command is a matter that directly concerns the public and the departments of public health. That ceaseless watchfulness should be maintained, that trained diligence combined with high scientific skill should be a means to attain efficiency, that appliances in use should combine simplicity with efficiency, that in their operation delay of all kinds should be avoided, and that the individual should receive consideration and every comfort and convenience enlightened civilization can provide, are axiomatic facts.

Our great seaports and ports of entry are the centers most exposed to contagion and infection. Disease germs from the civilized and uncivilized parts of the world tend to drift there, carried by an ever-moving stream of emigration and traffic. The larger the center, the greater the number that pass through it to gain access to other parts of the country, carrying with them whatever of good or ill they may bring. Their baggage and clothing, if from infected ports, can carry the seeds of disease and afford favorable conditions for the reproduction of germ life.

The port of New York, with its magnificent harbor and immense marine commerce, is one of the centers that requires intense, concentrated vigilance to protect the city itself and the country at large. One of its great dangers is that of disease brought by incoming vessels.

The health officer of the port of New York has charge of the

health of all of those on incoming vessels. The headquarters of the boarding station is situated at the Narrows, on the Staten Island shore. Side by side are the grim fort and the health officer's headquarters—the one an arm of the nation, the other a department of the State; both there to guard and protect the safety of the country. Detention at quarantine has been a precautionary measure, the disinfecting process slow and laborious.

Disinfection is the destruction of germ life. The penetrative quality of the means is a most important factor. Access to the seeds of disease, destruction of germ life, and the removal of conditions favorable to the reproduction of germ life are necessary to effect thorough disinfection. The destruction of the germ to be effected without the destruction of property or unnecessary inconvenience or delay is the problem.

The means in use consists of a steam disinfecting chamber (two hundred and thirty degrees of heat is destructive to germ life); bichloride of mercury used in solution of 1 to 1,000 or 1 to 1,200; sulphur fumes, which last have but little penetrative quality; and sea-water and salt-water soap for bathing purposes, to be used when necessary. It has been found expedient to combine these means and construct apparatus to enable the process of disinfection to be carried out rapidly and thoroughly.

The floating disinfecting plant system now contains all that is needed to effect a thorough and complete disinfection. The people detained are submitted to a rapid and efficacious process of cleansing and disinfection, their clothing being treated simultaneously, and their privacy considered even when under strict supervision. The officers in charge can direct and control all operations from the central part of the vessel, and, being provided

|

| Door of Disinfecting Chamber closed. |

with separate toilet and disinfecting facilities, can return to their quarters or gain access to any part of the vessel without danger of conveying infection and without delay. Fitted with the combined apparatus, a boat containing the plant can be run alongside the suspected vessel, which can then be thoroughly cleansed, disinfected, and fumigated, the passengers and crew bathed, their clothing subjected to steam sterilization, and returned to them uninjured, and all baggage and bedding treated to a complete disinfection. The crew and attendants have their comfort and health cared for separately.

Under the direction of A. H. Doty, M. D., health officer of the port of New York, the old side-wheeler Ripple has been remodeled. She looks new from end to end, and under the name of James W. Wadsworth presents a very trim, businesslike appearance. Inside she is arranged to economize every available inch of space, and is finished in such a manner that no germs of disease can be left to lurk undestroyed.

The Wadsworth has a twofold duty to perform: the bathing and disinfection of passengers, crew, and baggage; and the cleansing, disinfection, and fumigation of their vessel.

The passengers and crew and their effects are transferred to the disinfecting boat for treatment, and their vessel is thoroughly disinfected before they are permitted to return to it.

To effect this work with rapidity, there are several separate processes, each with its own set of apparatus, conveniently located. Each or all can be operated from the central part of the vessel, where the officer in charge of the disinfecting processes is stationed.

The plant contains a disinfecting chamber; bichloride tanks, with separate pumps and hose system; soda tank and hose system; salt-water pump and connections for the baths; sulphur furnace with air pumps and reservoir; and a central office, containing indicators and the controlling apparatus of the entire disinfecting system.

The boat is fitted with two immense fresh-water tanks; and the officer in charge can supply the baths with hot or cold, fresh or salt water at his discretion.

Outside, huge pipes, extra tanks to contain solutions, and conveniently situated cocks are visible. The railings have all been rearranged, to facilitate the handling of passengers.

The boat is practically divided into three sections: the after part of the vessel, which is devoted to the care, disinfection, and handling of passengers; forward, the crew's quarters; and the central part of the vessel, containing the boiler, engines, pumps,

|

| Discharging End of Disinfecting Chamber. |

and furnaces, and the room where the operations are controlled, and a separate set of disinfecting and toilet apparatus for the use of the officers in charge.

The disinfecting chamber is situated in the center of the after part of the vessel. Surrounding it are the reception rooms, disrobing rooms, bath rooms, and dressing rooms.

In a process of this kind it is necessary to take every precaution against the spreading of disease. This is provided for in the finish of the boat, which offers no resting place for disease germs to accumulate. All parts of the boat where the disinfecting processes take place are lined with sheet iron, finished with white enamel. The floors are of sheet lead, each furnished with a separate outlet pipe. Each room has a separate floor, which does not directly communicate with adjoining rooms; and the lead floors are protected with rubber mats, which can be treated without injury to a washing down with bichloride solution. The benches and other fixed furniture are set away from the walls to facilitate cleansing, and,

Car receiving Packages before being run into Disinfecting Chamber.

together with their fittings, are finished in white enamel, affording free surfaces, readily cleansed and disinfected.

The two bath rooms—an illustration of one of which is shown—are provided with showers and extra flexible hose connection for hosing down. The baths and the temperature of the water used are regulated in the central office; and the hot and cold levers are so arranged that the cold water always precedes the hot, thus preventing a sudden or too great rise of temperature in the flow of water when distributed by the showers.

The passengers are assembled for disinfection aft, on the upper deck. From there they descend to the reception room, which is situated over the stern. Opening from the reception room, on either hand, are the entrances to the disrobing rooms. Entering one of these, the passenger to be disinfected removes all clothing, which is then made into a bundle, checked, and tossed through a convenient opening into the receiving car of the disinfecting chamber. The passenger proceeds through a door opposite to the one by which he entered to the bath room; from there again, through another exit, to the dressing room, where the bundle of clothing awaits him, disinfected.

Thoroughly cleansed and disinfected, the passenger emerges clothed to proceed to the upper deck, to which there is a convenient staircase situated outside the dressing-room door. In a separate railed portion of the upper deck the passengers collect, and from there are returned to their vessel.

The entrance to the room into which the receiving end of the

One of the Bath Rooms.

disinfecting chamber opens is between the entrances to the two disrobing rooms.

The room into which the receiving end of the disinfecting chamber opens is finished in iron, enamel, and lead, as are all the other rooms. Overhead is a hatch in the upper deck, through which such large bundles as bedding, etc., can be lowered into the receiving car. The car of the disinfecting chamber is run out or into this room on rails. These rails are movable, and can be taken up and replaced at will. In operating the disinfecting chamber these rails are placed in position, the door of the disinfecting chamber opened, and the car or crate run out. Into this car the bundles of clothing are tossed from the disrobing rooms, which

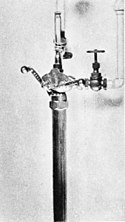

Bichloride Tank.

are situated on either side. From the deck above the bedding and other large objects to be disinfected are lowered into the car through the hatch. The car is then run into the disinfecting chamber, the door closed, and the process of disinfection commences. The door of the disinfecting chamber requires special mention. It is made of steel, protected by asbestos-magnesia covering, and is swung into place from a crane and secured by turnbuckles against a rubber gasket, effecting a perfect seal. The door is so hung that one man can handle and swing it even in a seaway, which is obviously a great advantage.

The disinfection of bedding, clothing, etc., is accomplished by means of steam sterilization. The penetrative quality of the means must be rendered effective.

The disinfecting chamber is a huge steel room or chest, and in it the clothing, etc., are treated. A vacuum is created in the chamber and live steam introduced and exhausted until every part of the contents of the car has attained the desired degree of heat.

The bundles into which the clothing, etc., are rolled are securely fastened before being tossed into the receiving car, and remain there undisturbed, each numbered, to effect rapid identification.

The rapidity and thoroughness of this disinfection depend on the vacuum-system process.

The air is drawn from the disinfecting chamber, and as the vacuum increases the air is withdrawn from the interstices of the fabrics to be disinfected.

Advantage is now taken of the fact that a rise in the temperature takes place rapidly in a vacuum. To effect the rise in temperature, to attain the necessary degree of heat, live, dry, superheated steam is admitted to the interior of the disinfecting chamber. This steam contains in reality little more water than the air that was withdrawn, being in a finely divided state at the high temperature at which it is introduced into the vacuum. The

Sulphur Supply Pipes.

temperature is easily maintained, there being no air to convey away the heat; and the steam penetrates to every interstice of clothing or fabric.

After a proper temperature has been maintained for a sufficient length of time, cool air is admitted to the chamber and exhausted alternately, until the temperature is sufficiently lowered, when the clothing, etc., is removed and distributed.

The car is discharged at the opposite end of the chamber from which it entered. The huge steel chest of the disinfecting chamber is double jacketed, and protected by asbestos-magnesia covering. The operations of the chamber are controlled by means of a Foster valve.

The interior of the disinfecting chamber has fixed rails for the car to run upon, and is also fitted with a shield to protect the contents of the car from damage by condensed moisture. All water formed on the roof of the chamber drops from the

|

| Sulphur Furnace. |

shield into a receiving pan, and can be drawn off from there by a separate connection. The clothing treated is not injured in any way.

The discharging end of the car opens into the room where the health officer controls the disinfecting system. This end is fitted with a door similar to the one already described. In operating the chamber, one door is closed first, and steam admitted to the jacket, and as much air expelled by expansion as possible before the second door is closed. Then the air is exhausted and the vacuum process effects a thorough disinfection.

The vacuum is produced by the siphon process: steam under high pressure is driven across the end of a tube leading into the interior of the disinfecting chamber. This tube is fitted with valves and cocks. The jacket of the disinfecting chamber is fitted with separate valves and cocks, and the temperature can be raised, if desired, without admitting steam to the interior of the disinfecting chamber.

The Wadsworth has but one boiler, but that is large for the size of the boat. It supplies steam power to work the entire disinfecting system, as well as the power to run the boat's engines. The top of the dome of the boiler is fitted with a pipe leading to an extra dome; this is the reservoir that supplies the heated steam for the disinfecting chamber. The engines supply power to all the different pumping systems in the vessel; and fitted as the Wadsworth is with such powerful and complete pumps and hose system, she can be used as a fire boat should occasion require.

There are pumps for hot water, for cold water, for sea water, for bichloride solution, and for soda solution. The salt-water pump is made of composite metal. Ball-nozzle hose are used.

The sulphur furnace has four pans, each large enough to contain a couple of pails of sulphur. The sulphur fumes are collected and retained in a tank above the furnace, and drawn off as needed by a rotary fan, to be distributed through a huge system of supply pipes. About four pounds of sulphur to one thousand feet of cubic space is used. After the sulphur dioxide is forced through the pipe system, the sulphur can be cut off and fresh air forced through the same pipe system.

In disinfecting a vessel the soda solution is used to remove grease and render accessible surfaces in constant use, which are then washed down with the bichloride solution, which is followed by a thorough rinsing of sea water.

The crew's quarters of the Wadsworth have a separate freshwater tank and separate bathing and toilet facilities. Cedar is the wood used throughout the forecastle, which is finished so that whitewash can be readily applied. All parts of the vessel that carry the disinfectant plant are finished so that they can be thoroughly hosed down without danger of the waste being carried to the bilge. The ventilation is as nearly perfect as possible; all the rooms and quarters have plenty of light and air.

The clothing can be treated in a very few minutes, and the rest of the process is both rapid and efficacious. The boat is in commission, and the tests have all proved satisfactory.

Now that such progress has been made in the right direction, we shall expect to see our local health departments equipped with something similar, that is at once compact and capable of cleansing and disinfecting either a room or a district at short notice.