Popular Science Monthly/Volume 81/October 1912/The Guayule: A Desert Rubber Plant

THE

POPULAR SCIENCE

MONTHLY

OCTOBER, 1912

| THE GUAYULE—A DESERT RUBBER PLANT[1] |

By Professor F. E. LLOYD

MCGILL UNIVERSITY

PERHAPS no statement in regard to the source of our commercial rubbers is more surprising to one unacquainted with this particular field than that over 200 species of plants contribute to the sum total of the crude material which comes to the market. Indeed, that "rubber plant" which is frequently used as a household decoration is usually thought to be chiefly responsible, but this is far from the truth. This same rubber plant, however, furnishes us with a point of departure for the present account in the fact, well known to every one who has but slight acquaintance with it, that when injured, a milky fluid (latex) escapes, which, on drying, becomes translucent, and displays in some degree the familiar properties of india-rubber, or caoutchouc.

Diverse as are the plants which furnish caoutchouc, until a few years ago practically all of it was obtained by "tapping." This consists in cutting into the bark of the plant, and collecting either the milk (latex), to be coagulated immediately or later by various methods, or the strings and masses of coagulated latex adhering to the wound or elsewhere. Among the latex plants the only exception worthy of mention is the so-called grass or root rubber of the Congo. The rhizomes of the various species, which, because of their position, can not be tapped, are collected and dried, whereby the rubber is coagulated in the latex-tubes. It is subsequently extracted mechanically by heating, under such conditions as to separate the rubber from the fiber. It will appear evident that whenever the rubber exists as such within the plant, either as the result of coagulation or for any other reason, other methods than that of tapping must be resorted to for its extraction. The practise in the case of the root-rubbers suggest comminution of the tissues, accompanied by the agglomeration of the contained rubber. The methods of the chemist have suggested extraction by the use of suitable solvents, the rubber being recovered by differential solution and distillation of the solvents. Both these methods have been adapted to the extraction of rubber from the plant which shall claim brief attention in what follows.

I refer to the guayule, a low, gray or greenish-gray shrub (Figs. 1 and 2).

of limited distribution within the Chihuahuan desert, having the center of its geographical area very near to the northern boundary of the state of Zacatecas, Mexico. The southern extension of this area lies somewhat below San Luis Potosi; to the north it is found in the Big Bend country of Texas; here are rather small amounts, and of low stature as compared with the conditions farther to the south. The plant scarcely invades the state of Sonora, and is found only in the western part of Nuevo Leon.

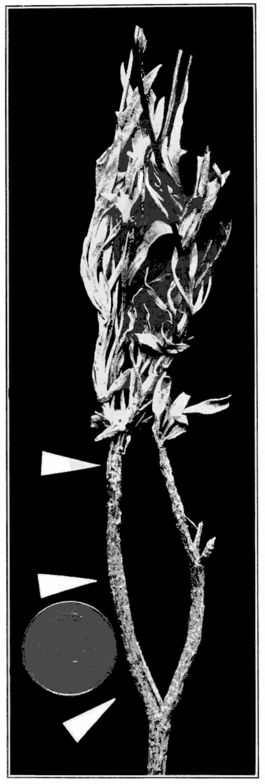

The chief interest attaching to its occurrence in Texas is the fact that it was here first discovered by Dr. J. M. Bigelow "near Escondido (Hidden) Creek." The party of the Mexican Boundary Survey, of which Bigelow was a member, in all probability rested at the large spring which forms the source of this creek, a camping-place for uncounted generations of Indians before the days of the white man. Here, on the McKenzie ranch, east of Fort Stockton, the writer also  Fig. 2. A large Guayule Plant, probably 50 years old. The measure is one meter.

Fig. 2. A large Guayule Plant, probably 50 years old. The measure is one meter.

Fig. 3. The Specimen of the Guayule on which Asa Gray based his original description. After a photograph. camped, finding traces of earlier travelers in arrow-points, beads and old-fashioned army copper cartridge shells. On the surrounding slopes the guayule grows, and probably here Bigelow in 1852 found the specimen on which the description published by Asa Gray in 1859 was based.

Fig. 3. The Specimen of the Guayule on which Asa Gray based his original description. After a photograph. camped, finding traces of earlier travelers in arrow-points, beads and old-fashioned army copper cartridge shells. On the surrounding slopes the guayule grows, and probably here Bigelow in 1852 found the specimen on which the description published by Asa Gray in 1859 was based.

For a good many years that specimen (Fig. 3) lay in the Gray Herbarium awaiting its apotheosis. So little was the plant known till recent years that even Bray does not mention it in his description of the vegetation of western Texas, written in 1906. In fact, it was less than a year and a half previous to this date that, as the result of the efforts of Mr. William A. Lawrence, backed by American capital, it was for the first time demonstrated that it was possible to extract the rubber from the guayule by a mechanical process. On December 25, 1904, 50 pounds of crude guayule rubber were shipped to and sold in New York city. This was the beginning of the immense operations of the Continental-Mexican Rubber Co. at Torréon, Coaliuila.

Fig. 4. Prehistoric Rubber found 14 Miles from Sasco, Arizona.

Fig. 4. Prehistoric Rubber found 14 Miles from Sasco, Arizona.

But the earlier history of the industry in Mexico has a larger romance than can well be related in the short space here allotted. The more salient points only may be mentioned. Just as the Mayas in the south, and in the Amazon region, made playing 1 tails of latex rubber, so, in the north, guayule rubber was known and used by the aborigines. But the task of extraction was for these more indirect, for they chewed the bark of the plant, in order to separate out the fibrous tissue and to agglomerate the rubber. Assiduous mastication on the part of a sufficient number of devotees to pelota turned out in a short time a resilient if crude rubber ball. There is evidence that this plaything found its way by barter to the coast of the Gulf of California and probably the peoples to the north and east also obtained it.  Fig. 5. Microscopic Appearance of Guayule Rubber in the Cells of the Rubber-bearing Tissue. It is a matter of unusual interest that the aboriginal Papagos used rubber. Late in 1909 an olla, or earthenware jar, was unearthed at some depth on the site of an ancient village near Sasco, Ariz. In it were two round masses of rubber which, aside from a vitreous and fissured external layer, still displayed the texture, resiliency and odor of a dry and almost resin-free product. A generous piece (Fig. 5) of one of the

masses was presented to the writer by Professor A. H. Forbes, of Tucson, Ariz., for study, but the microscopic evidence does not support the most natural supposition that it is guayule rubber, but more probably that it is a latex rubber which found its way northward from the more remote parts of Mexico. It is fairly certain, therefore, that rubber was an article of barter over a rather wide stretch of country.

Fig. 5. Microscopic Appearance of Guayule Rubber in the Cells of the Rubber-bearing Tissue. It is a matter of unusual interest that the aboriginal Papagos used rubber. Late in 1909 an olla, or earthenware jar, was unearthed at some depth on the site of an ancient village near Sasco, Ariz. In it were two round masses of rubber which, aside from a vitreous and fissured external layer, still displayed the texture, resiliency and odor of a dry and almost resin-free product. A generous piece (Fig. 5) of one of the

masses was presented to the writer by Professor A. H. Forbes, of Tucson, Ariz., for study, but the microscopic evidence does not support the most natural supposition that it is guayule rubber, but more probably that it is a latex rubber which found its way northward from the more remote parts of Mexico. It is fairly certain, therefore, that rubber was an article of barter over a rather wide stretch of country.

At the present time not only guayule, but two at least of its congeners, "mariola" (Parthenium incanum) and "tatanini" (Parthenium lyratum) afford material to the hand of the ball enthusiast of northern Mexico. These two plants, however, contain rubber in very meager quantity as compared with guayule.

This method of extracting the rubber, viz., by mastication, very naturally suggested the course of manufacture. As early as 1888 it was

proposed to extract the rubber "by a process of grinding and washing." A test carried out in New York by the interested company showed that the "bark" contained at least "18 per cent, rubber comparable to the best grade of centrals." But nothing further was done and samples sent about this time from Mexico to Germany and England, found no favor.

In 1900, however, some Germans established a laboratory at San Luis Potosi, the birthplace of the industry in Mexico. Two years later, as a result of the San Luis investigations, a factory was started at Jimulco, in which a method of extraction by solvents was used. It was at this time that the experimental operations carried on by Mr. Lawrence and leading to the practical solution of the mechanical method, culminated in the first commercial shipment of crude guayule rubber, extracted by mechanical means. This was the American and, indeed, most important contribution to the solution of the problem, and led, as above stated, to the establishment of the works of the Continental-Mexican Rubber Company.

That the rationale of the mechanical operations involved may be appreciated, we may now consider in some detail the structure of the plant. The guayule shrub, having the low, tree-like habit of many desert perennials, belongs to the family Compositæ of which our daisies and dandelions are familiar examples. The most obvious proof of this relationship is seen at once in the flowers, which, while not very daisy-like at first glance, are seen in somewhat closer examination to follow the same pattern. Instead, however, of the rather numerous white rays surrounding the yellow center of the well-known daisy, in the guayule the short rays are but five in number, and these, as well as the relatively large disc, are of a uniform pale, dullish yellow. The flowers, unusually for the Composite, have a distinct and very pleasing fragrance, and are visited, and incidentally pollinated, by various small insects, even mosquitoes. The leaves, which may or may not be lobed, according to their development, are clothed with a dense, smooth covering of T-shaped hairs, imparting to them the silvery sheen characteristic of the shrub as a whole.

The smaller twigs are similarly clothed, the hairiness giving way at length to a smooth gray bark, which, with advancing age, becomes longitudinally fissured. On the oldest and largest stems, transverse Assuring takes place. On the whole, however, the surfaces of the branches are smooth and gray, contributing to the general neutral aspect of the plant. But most striking of all the characters is the "feel" of the lesser branches when bent, suggesting a weak wooden rod encased in a firm rubber tube. The branches have little strength, the mechanical elements of the wood being relatively few. An examination of a thin slice taken transversely through a smaller branch will enable us to gain some impression of the structure and especially of the manner of occurrence and distribution of the rubber. A twig about a year old taken at the end of a prolonged drought period will serve our purpose.

Referring to Fig. 9, the reader will note that several concentric zones of tissue appear. The outermost is cork (ck), which contains no measurable amount of rubber in small branches. In old thick stems the formation of cork in the deeper layers of the next occurring zone, the cortex (cr in the figure), results in the cutting out of rubber-bearing tissue, accompanied by a degeneration of the rubber itself, and its consequent loss. The cortex comes next. It is made up of cells of uniform size and shape, containing chlorophyll, and hence green in color. In each cell appears a large droplet of rubber, occupying nearly the whole of the interior space (Fig. 9). Here and there are oval openings which are sectional views of so many canals (rc) which traverse the cortex longitudinally. These contain a pale yellow resin, a commonly occurring material among the Compositæ. Any slight wound of the cortex, however caused, may open one or more of these canals, and the resin may then escape. Hardened, limpid drops of this, either clinging to the branches or fallen on the ground beneath, are always to be seen. The resin appears to be of little economic value, as it is soft. During the mechanical extraction of rubber, it becomes mixed with upwards of 20 per cent, resin.

Inwardly the cortex is broken up by radially placed masses of tissue partly composed of hard "bast" fibers (bf. Fig. 9). These correspond to the fibers of the flax in position and origin. Crude guayule rubber

always contains fragments of minute fibers, single or in bundles, and. together with other fragments of cell walls, enable one to determine the origin of the rubber microscopically.

From the inner limit of the cortex, extending toward the center, are radial, wedge-shaped masses of wood (w, Fig. 9). This is composed of mechanical tissues with water vessels scattered irregularly  Fig. 9. Semi-diagrammatic Sketch of Two-year-old Guayule Stem in Transverse Section. throughout it. These may be identified by the width of their lumina. At the inner ends of the wood masses may occur additional bundles of "bast" fibers.

Fig. 9. Semi-diagrammatic Sketch of Two-year-old Guayule Stem in Transverse Section. throughout it. These may be identified by the width of their lumina. At the inner ends of the wood masses may occur additional bundles of "bast" fibers.

The central area is occupied by the pith composed (p in the figure) of cells identical in every detail except in shape with those of the cortex. The pith cells are nearly circular in outline. The)', too, contain rubber. Extending from the pith to the cortex and separating the wood bundles from each other, as also the bast bundles, are the so called medullary rays (mr). Their cells, flattened tangentially, are otherwise quite like those of the cortex and pith, are equally rich in rubber. The pith, again like the cortex, is traversed longitudinally by resin canals. A point of interest here is that the canals with age become plugged by ingrowing masses of tissue, thus in a measure preventing the leakage of resin, especially in the cortex when invaded by cork. In the pith there is an undoubted downward leakage of resin, which, infiltrating into the older wood below, may be detected by chemical analysis. It is thus evident that the resin content of guayule wood is accidental.

By subsequent growth, year by year additional layers of bast and wood are laid down at the inner limit of the cortex, where the cambium, or actively growing tissue, is situated (c, Fig. 9). In the bast, and here alone, new resin canals are formed, in radial rows, therefore.

From this very curtailed description, it appears that, in the guayule, the rubber occurs as droplets—really very minute—each enclosed in a sac of albuminous material (protoplasm), this again surrounded by a sac of cellulose (the cell wall). All the cells of the pith, medullary rays and cortex (and certain others which we need not mention here) contain rubber. There is no rubber in the canals, nor is there any rubber, or rather latex, vessels. It is for this reason that, while it is not possible to extract the rubber by tapping, it is possible, by comminution of tissues, to work together or agglomerate the minute particles of rubber set free by breaking the cells which hold them. It is equally evident that chemical agents may be used for extraction by solution, but this process is of less interest in this connection. We may now pass on to examine the methods of handling the shrub and the process of mechanical extraction.

Collecting the Shrub

The primary problem of collecting the shrub and transporting it to the factory is a difficult one. The shrub, growing wild, being contracted for, the purchaser is free to go and get it. This means that

peons must be hired to collect the plants in desert places often far removed from water and other supplies. They and their burros find their way into steep and rocky places unapproachable by other means. Having pulled up by the roots a carga of shrub, it is loaded on a burro and so off to a central camp, "campo de guayule" placed so as to be approachable by wagon. Here the shrub is baled after the fashion of so much hay. The bales are then hauled to the nearest railway station, sometimes 100 kilometers away, to be shipped to the factory.

Arrived there, the bales are weighed for comparison with the field weight. A certain amount of shrinkage is of course expected, owing to the drying out of the shrub and breaking off of twigs. Since it was found possible to increase the field weight by methods devious and of little cost, thus selling stones or water at an exceptional price even in a country where that commodity is not cheap, a control by means of tags was devised, enabling a systematic comparison of the field and factory weights of shrub from all areas. The price of water quickly fell.

Manufacture

To keep a large plant running regularly a considerable reserve of shrub must be held. This was formerly stacked in the open, but later, when rapid deterioration was discovered, suitable storage warehouses were provided, thus obviating the deleterious action of the sun. When

the shrub is in good condition—that is, sufficiently, but not too dry—the bales are passed out to a washing floor where all dust and soil is removed by a stream of water. The importance of this becomes apparent when it is reflected that the rubber picks up particles of soil and its specific gravity altered, so making the separation of rubber and bagasse more difficult.

The shrub is now run between the steel rolls of a crusher which, running at differential speeds, grind up the plants into torn fragments. Peons take this material up in baskets and convey it to pebble mills. These are short iron cylinders which are arranged so as to rotate on their axes. Each mill is lined with flint bricks and is charged with ground shrub, water and coarse flint pebbles which by their impact on each other comminute the shrub and agglomerate the rubber. After the milling is complete, which ensues after about 3,000 revolutions at the rate of 30 per minute, the mixture of water, comminuted shrub and bagasse is discharged and flows into skimming tanks. In these a portion of the bagasse, consisting of fibrous material (bast, wood) and fragments of other cell walls, sinks, while the agglomerated rubber ("worm rubber"), accompanied by a bagasse composed of minute flakes of cork, floats. This floating mixture can now be separated into practically clean worm rubber and rubber-free bagasse by boiling, and then by submitting it to a pressure of about 250 pounds under water, in order to water-log the cork flakes. A further cleansing of the worm rubber flakes takes place in a tank supplied with a paddle wheel, which beats the floating particles and so rids them of adherent particles. After this there remains but the "sheeting," which is accomplished by passing the worm rubber between corrugated steel rollers to form sheets. It may be packed in sacks in this form or pressed into solid blocks, say, of 50 pounds weight and packed in boxes. In this process it is evident that there are two critical phases, first the agglomeration of the rubber and, secondly, its later separation from the bagasse. The former is relatively easy or difficult, according to the richness of the tissues in rubber, or stated otherwise in the size of the rubber particles within the cells of the tissue. The separation of rubber from bagasse depends on the difference in their specific gravity, using this term in a loose sense. The fibrous elements, namely wood, bast and broken open cell walls, are easily waterlogged—that is, the occluded air is easily dispelled, while the cork is difficult to break up and even more so to rob of its air.

The coarse worm rubber floats rather readily; but the smaller the particles the more slowly they rise to the surface. Any means which may be used to cause a swelling of the particles, or to lessen the distance which they must travel to reach the surface, afford help in attaining to segregation of the rubber. The colloidal properties of rubber make swelling possible by means of any of its solvents. The depths of the tanks which are used for separation of rubber and bagasse is obviously important. When it is known that an extraction of 7 per cent, rubber (of which the moisture amounted to 25' per cent.) was raised during about five years to 15 per cent, by slowly improved methods, we may realize the amount of experiment and ingenuity necessary. It would have been well for the industry to-day if, during the earlier period, there had been less desire to take advantage of the ease of acquiring profit and more study and experiment. To be sure, a good deal of rubber left in the bagasse was later reclaimed, but the total lost in spite of this must have amounted to a good deal. This was, however, only one form of economic waste. By far the most serious lay in the method of gathering the shrub by pulling it up by the roots, called, however, by the euphonious name of "cortando," or cutting. Had the guayule actually been cut off at the level of the ground, new shoots would have sprung up in many instances to take the place of the removed plants.

Reproduction of the Shrub

It has always been fully realized that the limiting factor of the guayule industry is the rate of growth and of natural reproduction of the  Fig. 12. The Annual Accretion weight of Growth in a Guayule Twig of average rate of growth. "stand," unless the demand for shrub could be met by cultural methods. It is obvious that until the possibilities of culture could have been determined, the proper procedure would have been conservation of the mature supply by forestry methods. We may now examine the guayule plant from this point of view.

Fig. 12. The Annual Accretion weight of Growth in a Guayule Twig of average rate of growth. "stand," unless the demand for shrub could be met by cultural methods. It is obvious that until the possibilities of culture could have been determined, the proper procedure would have been conservation of the mature supply by forestry methods. We may now examine the guayule plant from this point of view.

The guayule is a woody shrub which, in common with most desert plants, is of slow growth under normal conditions. It affects the stony or rocky foot-slopes and foothills of the limestone hills and mountains within a region of uncertain and at best scanty rainfall. Few and imperfect records are available for the guayule region proper, but it is safe to say that the total precipitation does not exceed 10 or 12 inches. The effective rains fall chiefly in summer. The growth season is therefore short and the annual increment in growth in length of branches does not exceed an average of 3 to 5 cm. (Fig. 12). Plants certainly 50 years old do not exceed a meter in height or spread. I have never seen an old plant excelling in both dimensions. By careful measurements of numerous field plants it has been determined that it takes about 10 years for an individual to acquire a weight of about 8 ounces, but in the following five years it will make eight ounces more and will have arrived at an economic maximum. It may then be concluded that assuming an even stand of a ton to the acre, it requires 15 acres to supply one ton a year, allowing for good years and bad. Most guayule land will not yield so well. It is, however, clear that where the land is very cheap and can be used for other profit to a considerable extent without materially damaging the shrub, a conservative method of gathering could have been made to yield reasonable and constant returns.

It has been assumed that the stand is maintained by the reproduction of guayule by seed. Field studies have shown that this is true. Areas of known dimensions have been cleared of all plant growth, and the new seedlings counted; and censuses have been taken of such areas to determine the population of plants of various ages. The information obtained proves clearly that the more usual method of reproduction is by seed. It must be added that different localities often not widely separated show a very diverse efficiency in this regard. Indeed, it has often been difficult to see any evidence that if the present growth were removed there would be any effectual replenishment by seed. Such places are marked by the absence of small seedlings and usually carry only mature individuals of approximately the same size. But it by no means follows that in such situations there is no reproduction at all, for in addition to seedlings the guayule also increases its members by means of "retoños," that is, by new shoots which strike upward from the shallow lying lateral roots. In the course of time retoños establish their own roots and become entirely separated from the rest of the plant and consequently independent organisms. Retoños grow more quickly than seedlings and are more certain of arriving at maturity. Because of the previous establishment of the root they may develop where, on account of slight depth of soil, seedlings would fail. As a matter of fact they are relatively more plentiful on rough stony ground and are particularly prone to occur where the surface of the ground is steep and the roots become exposed by erosion, though this is not a condition necessary to their formation. Furthermore, they develop flowers in the first season of their growth so that, in the event that the guayule were removed they would constitute a pretty certain insurance against extinction.

Whether the cutting away of the aerial portion of the plant induces the growth of retoños or not has not been decided, but, as already said, it is followed by abundant reproduction of new shoots from the stocks left in the soil. These follow cutting in about 40 per cent, of the cases, so far as determined, but as the year when the censuses were made was a dry one the figure is probably low for a good season. The time when the cutting takes place doubtless also influences the result. Aside from this, however, these new shoots develop rapidly, but flower abundantly in the first season and are thus effective in reseeding the ground.

We see, therefore, that the guayule is by no means unequipped for its business of obviating the effects of untoward conditions in its environment. We may now inquire briefly into its response to cultivation.

Guayule under Cultivation

desired substances in the same amount as in the wild. When the problem of cultivating the guayule presented itself, the first question that arose, and most naturally, was the relation of secretion of rubber to the supply of soil water. Though there is no very good a priori ground for expecting one result or the other, it was known that the amount of rubber obtained from certain latex trees is influenced by the amount of soil water during the period of tapping. It was also found that in the guayule the occurrence of rubber in the new growths of the particular season intervenes only after a distinct interval of time, for which reason the collecting of the shrub at the close of the rainy season involves a great waste, since the increased weight is in no degree to be referred to a greater rubber content.

The careful study of the guayule plants which were under cultivation and had been freely irrigated developed, in addition to several other points of interest, the knowledge that the greater the amount of growth (itself dependent on the amount of water available), the slower the secretion of rubber and the smaller its total amount relative to the volume of the tissues. On the other hand, the rate of growth under irrigation is so much more rapid that the total volume of rubber-bearing tissue is very greatly in excess of that in field plants. Irrigated plants present other features of difference which must be taken into account by the manufacturer and which are of very great interest to students of the physiology of desert plants. I need mention only the more salient here, namely, the greater relative volume of the woody portion of the stem, its harder and more rigid character, the smaller volume of the cortex (bark) (Fig. 16) and the quantity of rubber in individual secreting cells.

The increased hardness of the "wood" in the irrigated plant is due, in part at least, to the reduced volume of the medullary rays. And as

these make up a goodly proportion of the volume of the smaller twigs in the field plants, and since the medullary ray cells contain rubber, the greater hardness of the irrigated wood is attained at the cost of rubber-bearing tissue. The lessened volume of the cortex and of the pith contribute to the same results, so that even if the "amount of rubber secreted by the individual cells remained unaffected by irrigation, the amount relative to the volume of the plant will be materially less. But so far as the writer's own observation goes the rubber cells in the plants which have been abundantly watered so as to extend the growing season over six or seven months, do not, even after subsequent sustained drought periods, contain the normal but rather a considerably less amount of rubber. This, from the point of view of the manufacturer, means that the globules of rubber which must be agglomerated into worm rubber in the pebble mill are smaller and farther apart and consequently more difficultly brought together. It means, too, that in obtaining a given amount of rubber much more bagasse must be handled. These difficulties may doubtless be overcome by suitable modifications in the details of the process already outlined.

The reader will have gathered the impression that the guayule may be grown readily under cultivation. This is true, at least in its areas of distribution and in adjacent or other areas of similar meteorological conditions. It does not, however, thrive in eastern Texas, judging from a specimen planted by Dr. H. H. York at Austin, nor in Alabama. Here it will grow rapidly the first season, but little the second. Further, a large percentage of the plants are killed by frost and dampness combined, whereas they will resist severe frost in dry regions. And again the amount of rubber in them is very small indeed. Why this peculiar relation of rubber secretion to soil water can not be said. The teleologist will doubtless see in rubber a means adapted to conservation of water in the desert plant. Field guayule, however, wilts almost immediately upon being pulled up, and its congener mariola, which is more drought-resistant, has even less rubber than irrigated guayule.

On the other hand, the larger development of the wood appears to be correlated with a more rapid growth, and consequently a larger production of leaves, made possible by a greater water supply. This logic is clearer when it is realized that the wood contains the water-carrying vessels and at the same time the mechanical tissue for the support of the foliage. From this point of view the more extensive rubber-bearing tissues and apparently greater succulence in field plants result from more meager development of the wood and do not speak for a larger "water balance," one criterion, at least, of drought resistance.

One additional feature of the behavior of guayule under irrigation, especially when grown from transplanted stocks, is worth mentioning in closing. It had been noticed that its congener, the mariola Parthenium incanum), does not produce retoños, as does the guayule, but sends up each season new shoots from the base of the trunk. These shoots root independently and in the course of events are separated by a constriction of the connecting tissue from the parent plant so that an old mariola plant is really a cluster of partially or wholly independent individuals. Such behavior is absent from guayule under normal conditions, but may be readily induced under irrigation, and in this way there is afforded the means of vegetative propagation which stands in lieu of the usual method of making cuttings, which has not been found possible up to the present.

The question which many will ask, whether it will pay to cultivate guayule, must remain, for the present, unanswered. That guayule may be propagated under cultural conditions, both by seed and vegetatively, has been demonstrated. That there are immense areas adapted to guayule and now almost profitless is almost equally sure. The problem seems to be how to get the plant started and to determine to what extent temporary irrigation, by manipulation of the run-off, will be justified on practical economic grounds. An experiment of large scope could be conducted so as to answer these questions and might reveal a new means of increasing our resources.

- ↑ For a full account see F. E. Lloyd, "Guayule, a Rubber Plant of the Chihuahuan Desert," Carnegie Institution of Washington, Publication 139.