Sheet metal drafting/Chapter 16

CHAPTER XVI

DEVELOPED AND EXTENDED SECTIONS

Problem 53

OVAL TO ROUND ELBOW

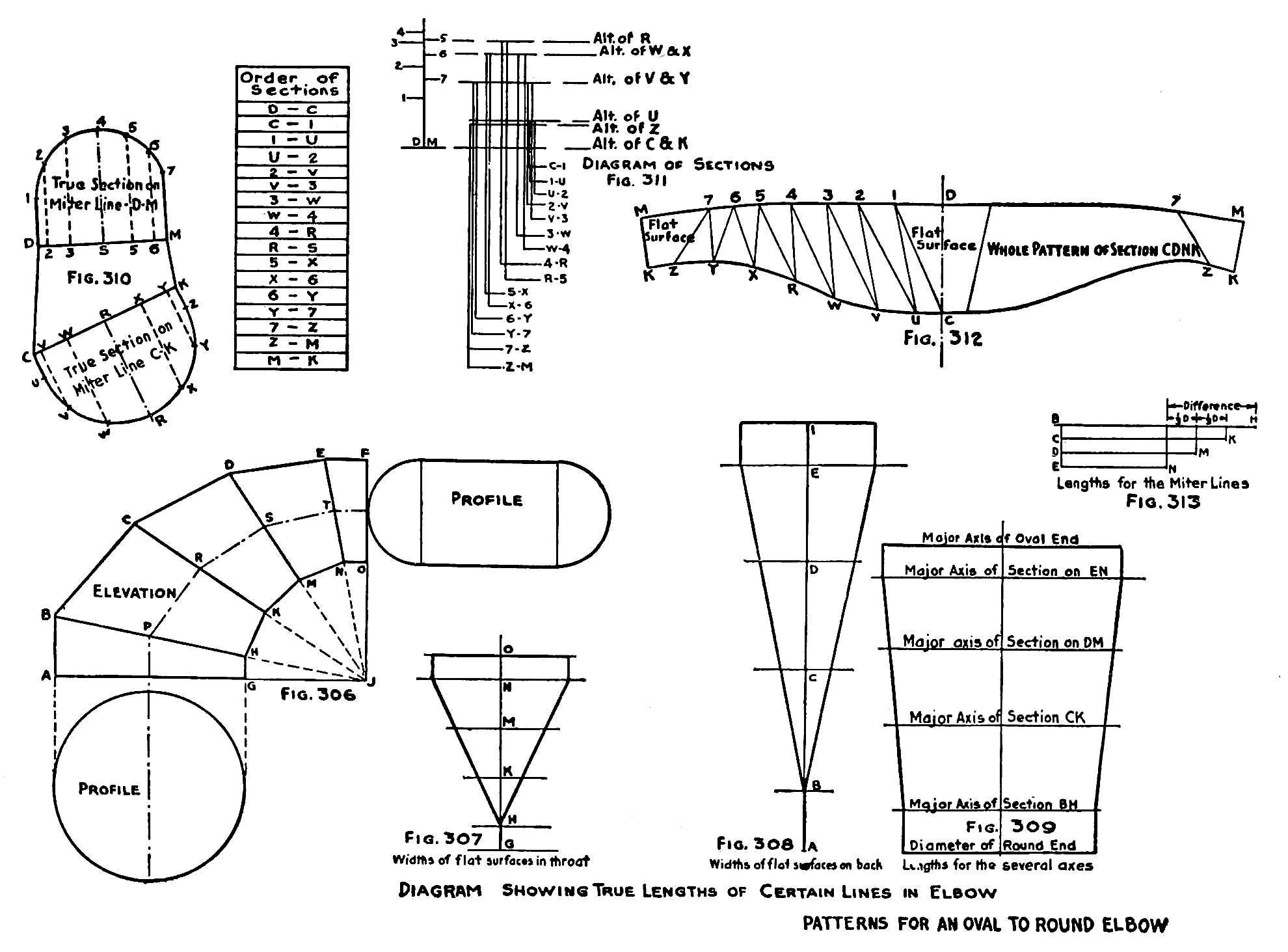

93. Oval to Round Elbow.—Figure 306 is an elevation of an elbow whose first piece is that of a five-piece round pipe elbow, whose last piece is that of a five-piece oval elbow, and whose intermediate pieces are transitions which gradually convert the round pipe to the oval pipe.

This elevation is constructed by first drawing an angle (angle AJF) equal to the required angle of the elbow. The throat radius is then laid off on the base line and the arc of the throat drawn in. This arc is then divided and the miter lines of the elbow are drawn as though the elbow were a regular round pipe fitting such as described in Chapter III. Lines AB, GH, ON, and FE are drawn at right angles to the lines AG and OF, thereby completing the elevation of the first and last pieces. The throats of the second, third, and fourth pieces are drawn tangent to the arc as described in Chapter III.

The length of miter fines CK and DM are now determined in order to complete the outline of the back. Since the reduction must be gradual, an equal amount must be subtracted from each succeeding miter line. A short and convenient method of finding these lengths is shown in Fig. 313. Four parallel lines are drawn and the lengths of lines BH and EN placed upon them so that point E is directly under point B. The difference in length between these two lines is divided into three equal parts and perpendiculars dropped from each of these points to the other parallel lines, thereby establishing the lengths of miter fines CK and DM.

These lengths are now placed on the proper miter fines in Fig. 306, and the outline of the back of the elbow is completed, by connecting points B, C, D, and E with straight lines.

Each miter line as it passes through the elevation is divided into two equal parts, thus locating center points P, R, S, and T. The center fine of the elevation may then be drawn by connecting these points.

The oval end of the elbow has two flat surfaces while the round end has none. Consequently, these flat surfaces must gradually diminish in width until they disappear upon reaching the round end of the elbow.

In order to develop the patterns it is necessary to know the exact widths of these flat surfaces at each cutting plane, and in order to gain this information stretchouts must be made as shown by Figs. 307, 308, and 309.

Upon any vertical line a stretchout of the throat of Fig. 306 is made as shown by points O, N, M, K, H, and G of Fig. 307. Through each of these points perpendicular lines are drawn. Upon lines O and N one-half of the straight line in the oval profile must be laid down on each side of points and N. Straight lines connecting these points produce a rectangle, showing the true shape of the flat surface in the throat of the last piece of the elbow. If this surface were allowed to taper, the oval pipe to which the elbow is joined would not fit properly. Since the flat surface is to disappear at the throat of the first piece, straight lines may be drawn from the extremities of line N to the point H, thus establishing widths at M and K.

The widths of the flat surfaces on the back of the elbow, as shown by Fig. 308, are developed in exactly the same manner, and the description given above may be used again by substituting the word back and the letters that correspond.

Since the major axis (long diameter) of the oval is greater than the diameter of the circular profile a gradual increase must also be made in the major axes of the sections formed by the several miter lines. A stretchout of the center line of Fig. 306 is made as shown by Fig. 309. On the horizontal line T the long diameter of the oval profile is placed (one-half on each side of point T), while on line P one-half of the diameter of the round profile is placed. Straight lines are then drawn connecting these points, thereby establishing the major axes of the sections formed by miter lines DM and CK.

The patterns for the first and last pieces can be drawn by the method described in Chapter III since they are pieces of regular five-piece elbows.

The intermediate pieces of the elbow must be developed separately, either by triangulation or sectional development. The third piece of the elbow has been selected for treatment in this description, but the second and fourth pieces are developed in exactly the same manner.

Figure 310 shows the third piece removed from Fig, 306, in order to avoid confusion of lines. At the center points R and S perpendicular center lines are erected. Upon the center line at S one-half of the major axis of section DM, Fig. 309, is set off; and upon the center line at R, one-half of the major axis of section CK, Fig. 309, is set off. These points are lettered 4 and R as shown. Perpendiculars are now erected at points D, M, K, and C. Upon these lines the following lengths are placed: line D–1 is made equal to one-half of line D in Fig. 308; line C–U one-half of line C in Fig. 308; line M–7 one-half of line M in Fig. 307; and line K–Z one-half of line K in Fig. 307. Arcs are now drawn connecting points 1, 4, and 7, and also points U, R, and Z. Sections are thus formed on cutting planes DM and CK, and while these are not absolutely true sections, as defined by the laws of projection, they are near enough for all practical purposes and can be constructed in much less time.

The arcs of these sections are divided into equal spaces and the divisions given numbers or letters as shown in Fig. 310. Perpendicular lines are dropped from each division until they intersect lines DM and CK.

The order of sections is now decided upon as shown by the order given upon the drawing. The base lines for the sections may or may not be drawn in Fig. 310, according to the amount of dependence to be placed on their guidance.

The diagram of sections, Fig. 311, shows the condensed form in which the experienced draftsman usually develops this feature of the problem. All of the altitudes of points in the profile of one end of the transition are placed upon a vertical line. From the intersection of this vertical line with a horizontal base line all of the base lines from Fig. 310 are measured. Above this horizontal line, other horizontal lines are drawn at distances representing the altitudes of the points in profile of the other end of the transition.

From Fig. 310 base lines are laid down upon the horizontal line of Fig. 311, and perpendicular lines are erected to the proper altitude. The upper base of the section can be measured with the dividers and used in developing the pattern.

Supposing the true length of the upper base of Section R to 5 is desired. Starting at the short line labeled R–5, the vertical line is followed upwards until it meets the horizontal line labeled Alt. of R. The distance between this point and point 5 on the vertical line at the left of the diagram is the required distance.

It sometimes happens that two base lines have the same lengths as is the case with C–1 and 1–U. To find the true lengths, starting at C–1, the vertical line is followed upwards until it meets the base line of the diagram (points C and K having no altitude) and from this point the distance to point 1 on the vertical line at the left of the diagram is measured. Again starting at 1–U the same vertical line is followed upwards until it meets the horizontal line representing the altitude of U. The distance from this point to point 1 at the left of the diagram is the true length sought.

Starting with a vertical line. Fig, 312, upon which the length of line DC of Fig. 310 has been placed, the pattern is developed in the usual manner by following the order of development, by sections, which has already been determined. The flat surfaces should be marked to aid the workman in forming the metal. The whole pattern may be produced by copying the pattern which has been developed on the other side of line DC.

Problem 54

BREECHES

94. Breeches.—Breeches is the trade name given to a transition between two round pipes and an oval or round pipe of larger diameter. The plan, Fig. 314, is that of a transition between two round pipes of unequal diameters, and an oval pipe. The plan is first drawn showing the branch pipes in their proper location. A horizontal and a vertical center line are then drawn in the oval profile. As will be seen upon examination the horizontal center line divides the figure into two equal parts; therefore, it is capable of being developed by sections. The vertical center line of the oval will be used as the miter line between the two branches.

The profiles of Fig. 314 are divided, as shown, after which extension lines are dropped and an elevation, Fig. 315, constructed. Each point in the profiles should be properly located by extension lines in the elevation.

The order of development should now be decided upon. As in the case of the split header. Chapter XV, the fitting should be considered from the standpoint of two separate transitions between oval and round pipes. In this problem the large branch is treated first and the order of development determined as follows:

| Intersection with Miter Line: | |||||||||||||

| Triangles | Triangles | Triangles | Base line | 3 | to | O | |||||||

| 5 | to | G | F | to | 3 | 2 | to | B | Base line | C | to | N | |

| G | to | 4 | 3 | to | E | B | to | 1 | Base line | 2 | to | M | |

| 4 | to | F | 3 | to | C | 1 | to | A | Base line | B | to | K | |

| C | to | 2 | Base line | 1 | to | H | |||||||

The base lines corresponding to this order are now drawn in Fig. 314 and their points of intersection with the miter line indicated by letters O, N, M, K, and H as shown. These are given in the fourth column of the above table, and should be placed in the diagram of triangles, Fig. 318, exactly as indicated; that is, base line 3 to O should be measured from point 3 in the diagram of triangles and not from point C.

The diagram of triangles is now drawn by taking the base lines from Fig. 314 in the order given above. Perpendiculars are erected as shown and since the planes of the transition are parallel all triangles will have the same altitude. This altitude is shown

by line 6-A of Fig. 315. Perpendiculars erected at points O, N, M, K, and H establish the position of these points on the hypotenuses of their respective triangles and enable the true lengths of these lines to be measured.

An elevation of these elements is now drawn in Fig. 315. Where these elements intersect the miter line the elevation of points O, N, M, K, and H will be established.

A true section on the miter line, Fig. 316, is now constructed by transferring the spacing of miter line HD in Fig. 314 to any horizontal line. Perpendiculars are erected at each of these points and corresponding altitudes, taken from Fig. 315, placed on them. Lines connecting the points thus located constitute a true half section on the miter line. The whole section may be produced, if desired, by copying on the other side of center line H, the half already developed.

The pattern for the large branch is started by placing on any vertical line a distance equal to the hypotenuse of triangle 5 to G. The pattern is developed in the usual manner by following the order of development previously determined upon.

After the pattern for a complete transition has been developed the miter cut is drawn in as follows: The distance from point C to point O on the hypotenuse of triangle 3–O–C is laid off from point C on line C–3 of Fig. 320. Similarly, the distances C to N, B to M, B to K, and A to H are laid off from points C, B, and A on their corresponding lines in Fig. 320. A curved line passing through these points gives the miter cut of the pattern. Particular attention must be given to keeping the direction in which these measurements are taken, the same in the plan, in the diagram of triangles, and in the pattern.

In order to miter the small branch with the large branch, the same section must be used on the miter line. Figure 317 shows a half plan of the small branch removed from Fig. 314 in order to avoid confusion of lines. All of the intersections have been transferred and it is necessary to consider a new order of development which is given below.

| True Length | 6 | to | A | Triangle | 8 | to | C | Section | 9 | to | M |

| Triangle | A | to | 7 | Triangle | 8 | to | D | Section | 9 | to | K |

| Triangle | 7 | to | B | Triangle | D | to | 9 | Section | K | to | 10 |

| Triangle | B | to | 8 | Section | 9 | to | O | Section | 10 | to | H |

| Section | 9 | to | N | ||||||||

The pattern, Fig. 321, is started by placing upon any vertical line a distance equal to the true length line 6–A. The development proceeds in the usual manner until completed. Spaces A to D are taken from corresponding spaces in Fig. 317, as are also spaces 6 to 10, Spaces D to H, however, are taken from corresponding spaces in the true section, Fig. 316. The development may be copied on the other side of line 6–A in order to obtain the full pattern.

Necessary laps for riveting the pieces together must be added to these patterns.

Problem 55

COAL HOD

95. The Coal Hod.—The coal hod is made in many different designs, and since there is no standard the manufacturer draws the design to suit his own ideas.

Figure 324 shows a half-profile of a coal hod, and since the center line divides the object into two equal parts the pattern can be developed by sections.

Figure 322 shows the plan of the coal hod after it has been cut by an imaginary plane and so placed that the cutting plane assumes a horizontal position.

Figure 323 is a half-profile of the bottom located in its relative position by means of extension lines.

Both profiles should be divided into equal spaces and each division numbered or lettered as shown. It is evident that line 1–10 of Fig. 324 is longer than line 1–10 of Fig. 322 (since a straight line is the shortest distance between two points). Because of this fact the distances between points in the profile, Fig. 324, are not true lengths.

Figure 325, which is sometimes called an extended section, must be developed in order to ascertain the true distances between these points. A tangent parallel to the bottom line of the coal hod is drawn through the plan as shown in Fig. 322. Since point 4 is the lowest part of the curve the tangent must pass through this point. Extension lines are then carried from each point in the curve until they meet the tangent as shown in Fig. 322.

Upon any straight line, Fig. 325, the exact spacing between points 1 to 9 of Fig. 324 are laid off. Perpendiculars are erected at each point, and upon each perpendicular a distance equal to that from a correspondingly numbered point in the curve to the tangent of Fig. 322 is set off.

A curve traced through the points thus obtained will give the exact distance between these points, and these must be used in developing the pattern.

The order of sections must now be determined, such as will be found on the drawing, and a diagram of sections, Fig. 326, constructed. The base lines for this diagram are taken from the plan, Fig. 322. The altitudes 1 to 10 are taken from Fig. 324, and the altitudes A to K from Fig. 323.

The pattern is started by placing upon any straight line a distance equal to line 1–A of Fig. 322, this being a true length line since it rests on the horizontal plane. From point A point 2 is established and the pattern proceeds in the usual manner, using Fig. 325 for the spacing between the numbered points, and Fig. 323 for the spacing between the lettered points. The space between points 9 and 10 is taken from Fig. 324, and the line K–10 of the pattern is taken from line K–10 of Fig. 322 since it rests on the horizontal cutting plane and is, therefore, a true length.The coal hod is generally made from two pieces of metal, locks being added parallel to lines A–1 and K–10 of pattern. However, if it is desired that the object be made from one piece, the development may be copied on the other side of line K–10 in Fig. 327.

TABLE A

| Number of Gage. |

Approximate Thickness in Fractions of an Inch. |

Approximate Thickness in Decimal Parts of an Inch. |

Weight per Square Foot in Ounces. |

Weight per Square Foot in Pounds. |

|---|---|---|---|---|

| 0000000 | 1/2 | 0.5 | 320 | 20 |

| 000000 | 15/32 | 0.4688 | 300 | 18.75 |

| 00000 | 7/16 | 0.4375 | 280 | 17.50 |

| 0000 | 13/32 | 0.4063 | 260 | 16.25 |

| 000 | 3/8 | 0.375 | 240 | 15 |

| 00 | 11/32 | 0.3438 | 220 | 13.75 |

| 0 | 5/16 | 0.3125 | 200 | 12.50 |

| 1 | 9/32 | 0.2813 | 180 | 11.25 |

| 2 | 17/64 | 0.2656 | 170 | 10.625 |

| 3 | 1/4 | 0.25 | 160 | 10 |

| 4 | 15/64 | 0.2344 | 150 | 9.375 |

| 5 | 7/32 | 0.2188 | 140 | 8.75 |

| 6 | 13/64 | 0.2031 | 130 | 8.125 |

| 7 | 3/16 | 0.1875 | 120 | 7.5 |

| 8 | 11/64 | 0.1719 | 110 | 6.875 |

| 9 | 5/32 | 0.1563 | 100 | 6.25 |

| 10 | 9/64 | 0.1406 | 90 | 5.625 |

| 11 | 1/8 | 0.125 | 80 | 5 |

| 12 | 7/64 | 0.1094 | 70 | 4.375 |

| 13 | 3/32 | 0.938 | 60 | 3.75 |

| 14 | 5/64 | 0.0781 | 50 | 3.125 |

| 15 | 9/128 | 0.0703 | 45 | 2.813 |

| 16 | 1/16 | 0.0625 | 40 | 2.5 |

| 17 | 9/160 | 0.0563 | 36 | 2.25 |

| 18 | 1/20 | 0.05 | 32 | 2 |

| 19 | 7/160 | 0.0438 | 28 | 1.75 |

| 20 | 3/80 | 0.0375 | 24 | 1.50 |

| 21 | 11/320 | 0.0344 | 22 | 1.375 |

| 22 | 1/32 | 0.0313 | 20 | 1.20 |

| 23 | 9/320 | 0.0281 | 18 | 1.125 |

| 24 | 1/40 | 0.025 | 16 | 1 |

| 25 | 7/320 | 0.0219 | 14 | 0.875 |

| 26 | 3/160 | 0.0188 | 12 | 0.75 |

| 27 | 11/640 | 0.0172 | 11 | 0.688 |

| 28 | 1/64 | 0.0156 | 10 | 0.625 |

| 29 | 9/640 | 0.0141 | 9 | 0.563 |

| 30 | 1/80 | 0.0125 | 8 | 0.5 |

| 31 | 7/640 | 0.0109 | 7 | 0.438 |

| 32 | 13/1280 | 0.0102 | 6½ | 0.406 |

| 33 | 3/320 | 0.0094 | 6 | 0.375 |

| 34 | 11/1280 | 0.0086 | 5½ | 0.344 |

| 35 | 5/640 | 0.0078 | 5 | 0.313 |

| 36 | 9/1280 | 0.007 | 4½ | 0.281 |

| 37 | 17/2560 | 0.0066 | 4¼ | 0.266 |

| 38 | 1/160 | 0.0063 | 4 | 0.25 |