Steam Locomotive Construction and Maintenance/Chapter II

CHAPTER II

BOILER SHOP

Boiler Plates and Making the Boiler Barrel. The steel plates are delivered into the boiler shop after they have been sheared to sizes about ½ in. larger all round than the finished sizes to which they are put together in the boiler. They must be of the very finest quality, since they have to undergo processes, such as flanging, punching, etc., which would inevitably crack or otherwise injure inferior material.

After their arrival, the plates are first straightened to remove any slight waviness, by passing them through a machine, sometimes known as a “mangle,” which has a number of hard steel rollers, usually four above and three below. By passing the plate through between the upper and lower rollers two or three times the irregularities are removed.

The length of the barrel of the boiler may vary from about 10 ft. to 16½ ft. in British engines. In boiler barrels up to about 12 ft. long, two plates are generally used instead of three plates as in former practice. For longer barrels three plates are usual, though two are sometimes used. Engines have recently been built for the Great Northern Railway, in which the barrel 11 ft. 5½ ins. long is made of a single plate. Such plates have the advantage of dispensing with a transverse riveted seam, and are consequently stronger, but large plates above certain commercial sizes are more expensive per ton weight.

The plates have to be joined together by riveted joints. Each plate is bent round to a true circle, and its edges which come together are covered with narrow plates both outside and inside the boiler. These narrow plates A A (Fig. 2) are called butt strips, and when fixed properly in place are riveted to the main plate to form a joint running longitudinally along the boiler. This forms one ring of the boiler barrel. The second ring is made similarly, and the two rings have then to be united by rivets to form the complete barrel. The latter joint is termed the transverse joint, and may be made from two rings of the same diameter, in which case a narrow weldless ring B must be riveted all round the circumference over this joint. More frequently, however, the front ring is made of smaller diameter than the back ring, just sufficient to allow it to enter telescopically inside the back ring for a short distance, the two then being riveted directly to each other.

The boiler illustrated in Fig. 2 differs from the one mentioned above in that it has three rings of the same diameter, which are united by single-riveted circular butt strips B, i.e., there is only one row of rivets on each side of the transverse joints. The longitudinal joints A where the ends of each ring are joined together have

Fig. 2.—Sections through Locomotive Boiler

Before the barrel rings are made and jointed, the straightened plates are marked off for the rivet holes. In British practice the holes are usually drilled, but in some works, and invariably in American practice, they are punched. Punching boiler plates is injurious to the metal immediately surrounding the holes, and therefore such holes are punched smaller than the finished sizes and afterwards enlarged by passing through them a tool in the form of a round drill with cutting edges, known as a “reamer.” This operation removes the damaged metal.

The exact position of each rivet-hole has to be marked off on each plate when punching is adopted, but when the holes are drilled five or six plates are taken at a time and only the top plate is marked off. The plates are then secured under a radial drilling machine (Fig. 3) and each hole marked on the top plate is drilled through all the plates by a single operation. The top plate is again used as a template or guide for drilling the holes in the next batch of plates.

The plates have also to be marked off at the edges all round so that they can be finished to the exact sizes. They may be done from the drawings in case only one or two boilers are being made, but when a large number are in hand the marking-off is usually done by template. The template is a sheet of metal cut out like a dressmaker’s pattern to the exact size of the

Fig. 3—Radial Drilling Machine for Boiler Plates.

by Messrs. William Asquith, Ltd. (Halifax.)

other holes drilled through it to show their positions. Finally the edges of the plates are machined to size in a special plate-edge planing machine, in which a cutting tool moves along the edge for the full length or width of the plate.

Fig. 4.—Diagram of Plate-Bending Rolls, in Cross Section. |

Fig. 5.—Boiler Shell Drilling Machine.

By Messrs. Campbells and Hunter, Ltd. (Leeds).

opposite each other.

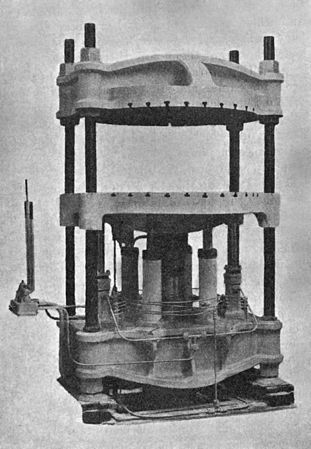

Fig. 6.—Hydraulic Flanging Press.

By Messrs Fielding & Platt, Ltd. (Gloucester).

The “throat plate” E E (Fig. 2), which connects the firebox shell to the barrel of the boiler, is of a complicated shape, and has to be flanged in two opposite directions, since the upper portion has to have its semicircular flange turned forward to join the boiler barrel, and the bottom part is flanged backwards to connect to the firebox shell wrapper plate. This plate requires extreme care when flanging to prevent damage to the material.

The sides and top F of the firebox shell are frequently made in one piece called the wrapper plate, which requires no flanging. The top portion is usually circular, and forms a continuation of the boiler barrel. This circular portion is produced by means of the plate bending rolls.

Assembling the Boiler. The boiler barrel is attached to the smokebox tube-plate by means of a continuous weldless angle iron ring G (Fig. 2). This is faced and bored in a large lathe or on a boring mill to fit over the end of the circular barrel plate, on to which it is shrunk by being heated slightly so that it expands. When put into place it contracts and grips the barrel plate, to which it is riveted all round the circumference.

The foundation ring H at the bottom of the firebox (Fig. 2) is a steel casting or forging of rectangular shape, the sides of which must be perfectly “square,” as it has to fit accurately between the inner copper firebox and the firebox outer shell or casing. It is machined and ground to accurate dimensions, the rivet-holes marked off and drilled, and then it is fitted to the firebox shell.

The whole of the plates and parts are then put together, and temporarily held in place by bolts through some of the rivet-holes. The structure has to be levelled carefully, so that the different plates are “square” and in line with one another. Careful measurements are made to see that the parts come together in accordance with the drawings or templates, and straightedges are used to test the alignment and “squareness.” When this is correct the riveting is done, except the foundation ring, which cannot be riveted until the inner copper firebox is put into place.

Riveting in former years was done entirely by hand, three men and a boy being employed. The boy attended to the heating of the rivets in a suitable portable furnace. One man placed the white hot rivet in the hole, and then held up the head tightly against the plate with a heavy “dolly” tool, which acted as an anvil to take the force of the blows. The other two men on the opposite side then hammered down the protruding shank of the rivet, until a head was formed. In present day practice hydraulic riveting machines are used invariably. These are shaped after the manner of the pincer claws of a lobster, which grip the rivet from both sides of the plates and squeeze it up in the hole. Before any riveting is done it must be seen that the holes come fair and true with each other, and if the marking off has been done properly to template this is usually the case. Any holes which may not come quite true are drilled or reamered out to a slightly larger size, and larger rivets are used in them. Holes which have been originally drilled instead of punched are more accurate in respect to true alignment.

An important point in putting the boiler together is to see that the expansion brackets or angle irons K (Fig. 2), which support the boiler on the frames at the firebox end, are perfectly level, otherwise the boiler may bind on the frame, and not expand properly when hot.

Dome and Safety Valve Seating. The dome L (Fig. 2), is formed of a small plate bent into a ring, the joint being either riveted or welded. It is flanged at the bottom in a press by means of blocks made to suitable shape. The flanged portion fits on to the circular barrel plate of the boiler, in which a circular hole has been made, and is riveted to it. The dome cover is a dished plate which is pressed into shape between blocks in a press, or sometimes under a steam hammer. The cover is secured to the dome, which has a faced flange or angle iron ring for the purpose, studs with nuts being used so that the cover can be removed when required. The safety valve seating and cover M are made in a similar manner.

After the boiler has been riveted up, the seams or joints are caulked. This is a process for making the joints thoroughly steamtight and preventing leakage, and consists in burring up the edges of the plates with a tool in the form of a chisel with a broad blunt edge. Care must be taken not to use a thin or sharp edge on the chisel or the plates will be injured and their edges forced apart. Caulking which was formerly done by hand, is now done by pneumatic hammers.

Inside Firebox: and Stays. The inside firebox N (Fig. 2) is of copper plates. These are planed at the edges, and the rivet and stay holes are marked off and drilled in the same manner as in the steel plates of the boiler and firebox shell. The flanging, however, is done usually by hand, the

plates being heated and hammered down over shaped blocks with wooden mallets. The firehole, the circumference of which has to be flanged outwards to join the doorplate of the firebox shell, is however dished in a hydraulic press. (In Fig. 2 the older form of firehole ring is used instead of the flanged construction.) The flanges are then cut level by placing the plates on the table of a large horizontal band saw, and setting them level for the saw to cut off the ragged edges and leave the flanges of the correct width.

The holes for the tubes in the copper firebox tubeplate, and also in the steel smokebox tubeplate, are marked off either by drawing them out in detail on the plates when an isolated engine is being made, or by marking their positions from a template when several engines are being built.

The firebox plates are fitted to the foundation ring, and are put together in a similar manner to those of the firebox shell. Rivets of very soft iron or steel are generally used for copper fireboxes, though copper rivets have been used in this country and are still used on some French railways. The riveting is done with a hydraulic riveter having a very long gap or jaws, but the pressure used on copper plates is considerably less than that used on the steel plates of the boiler. If the roof stays are of the girder or bar pattern (as at O, Fig. 2), they have to be marked off and fitted to the firebox before the latter is put into and secured to the steel firebox shell.

To put the copper firebox into place the boiler is lifted by a crane and turned upside down, so that it rests on its back supported on blocks with the bottom of the firebox casing upwards. The copper firebox is then lifted by the crane and gently lowered into the firebox casing. To accomplish this, the foundation ring, which has been placed temporarily in position, will have to be removed. The firebox has to be set by measurement and to the marked centre lines, so that it will occupy an exactly central position. When everything is correct, the firebox and the shell are riveted together through the replaced foundation ring with long rivets, and also at the firehole ring. The roof stay holes in both the firebox and the top of the shell, when direct roof stay bolts are used, are reamered out with long reamers, and the holes are tapped in position for the stay screw threads. The reamering and tapping of screw threads through the plates are done by means of pneumatic drilling machines. These are driven at high speed by compressed air, and are arranged to take drills, reamers, taps, etc., as required. It may here be mentioned that every modern boiler shop is equipped with a complete air-compressing plant, from which pipes are taken to every part of the shop. To a large number of points on these pipes, flexible tubes can be attached to serve pneumatic chipping and caulking hammers, portable drilling machines, etc., so that these tools can be used on any portion of a boiler, in whichever part of the shop it may be standing.

The holes for the short side stays are similarly reamered out and tapped.

The copper side stays are turned and screwed in automatic lathes. The threads have to be made very accurately, since it is essential that they should fit tightly into the “tapped” or screwed holes in the copper plates of the firebox and into the steel plates of the firebox shell. After having been screwed into position, either by hand or by a pneumatic machine, the ends of the stays are cut off to a definite length, which leaves a short length projecting on each side of the plates to be riveted over.

Tubes. The tubes are put in from the smokebox end, the holes in the front tubeplate being, for this purpose, made slightly larger than the outside diameter of the body of the tubes. The tubes themselves are enlarged at the smokebox end, and swaged down to a slightly smaller diameter at the other end where they pass into the firebox tubeplate. At the latter end the tubes project into the firebox for about ⅜ in. to allow for “beading over” the ends up against the copper tubeplate. They are tightened in the holes by means of a tube expander, a special tool provided with a number of rollers. This is placed inside the tubes, the metal of which is rolled outwards until they are a tight fit in the holes. In the case of steel tubes a ridge or beading is also rolled on the tube on the boiler side of the firebox tubeplate. Brass or copper tubes are expanded and secured by driving short pieces of steel tube (called ferrules) tightly into the ends which pass through the tubeplate. At the smokebox end the tubes are merely expanded, neither beading nor ferrules being used.

Mountings. The boiler is then sent to another part of the shop to have the “mountings” put on. This term includes all the brass and other fittings, such as safety valves, water and steam gauges, cocks, etc. In British practice the mountings are not screwed directly into the boiler plates. Steel “pads” or seatings of the same shape as the flanges of the mountings having been previously riveted to the boiler, the flanges are secured to these by studs. The joints are faced and scraped, and either made metal to metal with boiled linseed oil, or a thin sheet of asbestos slightly smeared with red lead is placed between the faces. The nuts are then tightened gradually to make an absolutely steam-tight joint.

Fig. 7.—Completed Locomotive Boiler.

The steam test pressure is limited to 10 lb. per sq. in. in excess of the working pressure of the boiler, and if this test is passed the boiler is painted with a good coat of anti-corrosive paint to preserve the plates, and is then ready for sending over to the erecting shop to be placed on the engine. Fig. 7 shows a locomotive boiler in its finished condition.[1]

- ↑ Fig. 7 is reproduced from the author’s book The Development of British Locomotive Design, by kind permission of The Locomotive Publishing Co., Ltd. The opening in the front of the firebox casing is special to this particular boiler, and does not exist in ordinary boilers of standard construction.