De re metallica (1912)/Book V

BOOK V.

Now a shaft is dug, usually two fathoms long, two-thirds of a fathom wide, and thirteen fathoms deep; but for the purpose of connecting with a tunnel which has already been driven in a hill, a shaft may be sunk to a depth of only eight fathoms, at other times to fourteen, more or less[3]. A shaft may be made vertical or inclined, according as the vein which the miners follow in the course of digging is vertical or inclined. A tunnel is a subterranean ditch driven lengthwise, and is nearly twice as high as it is broad, and wide enough that workmen and others may be able to pass and carry their loads. It is usually one and a quarter fathoms high, while its width is about three and three-quarters feet. Usually two workmen are required to drive it, one of whom digs out the upper and the other the lower part, and the one goes forward, while the other follows closely after. Each sits upon small boards fixed securely from the footwall to the hangingwall, or if the vein is a soft one, sometimes on a wedge-shaped plank fixed on to the vein itself. Miners sink more inclined shafts than vertical, and some of each kind do not reach to tunnels, while some connect with them. But as for some shafts, though they have already been sunk to the required depth, the tunnel which is to pierce the mountain may not yet have been driven far enough to connect with them.

It is advantageous if a shaft connects with a tunnel, for then the miners and other workmen carry on more easily the work they have undertaken; but if the shaft is not so deep, it is usual to drift from one or both sides of it.

From these openings the owner or foreman becomes acquainted with the veins and stringers that unite with the principal vein, or cut across it, or divide it obliquely; however, my discourse is now concerned mainly with vena profunda, but most of all with the metallic material which it contains.

Excavations of this kind were called by the Greeks κρυπται for, extending along after the manner of a tunnel, they are entirely hidden within the

Three inclined shafts, of which A does not yet reach the tunnel; B reaches the tunnel; to the third, C, the tunnel has not yet been driven. D—tunnel.

A—Shaft. B, C Drift. D Another shaft. E Tunnel. F Mouth of tunnel.

When a stringer junctions with a main vein and causes a swelling, a shaft should be sunk at the junction. But when we find the stringer intersecting the main vein crosswise or obliquely, if it descends vertically down to the depths of the earth, a second shaft should be sunk to the point where the stringer cuts the main vein; but if the stringer cuts it obliquely the shaft should be two or three fathoms back, in order that the junction may be pierced lower down. At such junctions lies the best hope of finding the ore for the sake of which we explore the ground, and if ore has already been found, it is usually found in much greater abundance at that spot. Again, if several stringers descend into the earth, the miner, in order to pierce through the point of contact, should sink the shaft in the midst of these stringers, or else calculate on the most prominent one.

Since an inclined vein often lies near a vertical vein, it is advisable to sink a shaft at the spot where a stringer or cross-vein cuts them both; or where a vena dilatata or a stringer dilatata passes through, for minerals are usually found there. In the same way we have a good prospect of finding metal at the point where an inclined vein joins a vertical one; this is why miners cross-cut the hangingwall or footwall of a main vein, and in these openings seek for a vein which may junction with the principal vein a few fathoms below. Nay, further, these same miners, if no stringer or crossvein intersects the main vein so that they can follow it in their workings, even cross-cut through the solid rock of the hangingwall or footwall. These cross-cuts are likewise called “κρυπταί” whether the beginning of the opening which has to be undertaken is made from a tunnel or from a drift.

Miners have some hope when only a cross vein cuts a main vein. Further, if a vein which cuts the main vein obliquely does not appear anywhere beyond it, it is advisable to dig into that side of the main vein toward which the oblique vein inclines, whether the right or left side, that we may ascertain if the main vein has absorbed it; if after cross-cutting six fathoms it is not found, it is advisable to dig on the other side of the main vein, that we may know for certain whether it has carried it forward. The owners of a main vein can often dig no less profitably on that side where the vein which cuts the main vein again appears, than where it first cuts it; the owners of the intersecting vein, when that is found again, recover their title, which had in a measure been lost.

The common miners look favourably upon the stringers which come from the north and join the main vein; on the other hand, they look unfavourably upon those which come from the south, and say that these do much harm to the main vein, while the former improve it. But I think that miners should not neglect either of them: as I showed in Book III, experience does not confirm those who hold this opinion about veins, so now again I could furnish examples of each kind of stringers rejected by the common miners which have proved good, but I know this could be of little or no benefit to posterity.

If the miners find no stringers or veins in the hangingwall or footwall of the main vein, and if they do not find much ore, it is not worth while to undertake the labour of sinking another shaft. Nor ought a shaft to be sunk where a vein is divided into two or three parts, unless the indications are satisfactory that those parts may be united and joined together a little later. Further, it is a bad indication for a vein rich in mineral to bend and turn hither and thither, for unless it goes down again into the ground vertically or inclined, as it first began, it produces no more metal; and even though it does go down again, it often continues barren. Stringers which in their outcrops bear metals, often disappoint miners, no metal being found in depth. Further, inverted seams in the rocks are counted among the bad indications.

The miners hew out the whole of solid veins when they show clear evidence of being of good quality; similarly they hew out the drusy[4] veins, especially if the cavities are plainly seen to have formerly borne metal, or if the cavities are few and small. They do not dig barren veins through which water flows, if there are no metallic particles showing; occasionally, however, they dig even barren veins which are free from water, because of the pyrites which is devoid of all metal, or because of a fine black soft substance which is like wool. They dig stringers which are rich in metal, or sometimes, for the purpose of searching for the vein, those that are devoid of ore which lie near the hangingwall or footwall of the main vein. This then, generally speaking, is the mode of dealing with stringers and veins.

Let us now consider the metallic material which is found in the canales of venae profundae, venae dilatatae, and venae cumulatae, being in all these either cohesive and continuous, or scattered and dispersed among them, or swelling out in bellying shapes, or found in veins or stringers which originate from the main vein and ramify like branches; but these latter veins and stringers are very short, for after a little space they do not appear again.

If we come across a small quantity of metallic material it is an indication; but if a large quantity, it is not an “indication,” but the very thing for which we explore the earth. As soon as a miner who searches for veins discovers pure metal or minerals, or rich metallic material, or a great abundance of material which is poor in metal, let him sink a shaft on the spot without any delay. If the material appears more abundant or of better quality on the one side, he will incline his digging in that direction.

Gold, silver, copper, and quicksilver are often found native[5]; less often iron and bismuth; almost never tin and lead. Nevertheless tin-stone is not far removed from the pure white tin which is melted out of them, and galena, from which lead is obtained, differs little from that metal itself.

Now we may classify gold ores. Next after native gold, we come to the rudis[6], of yellowish green, yellow, purple, black, or outside red and inside gold colour. These must be reckoned as the richest ores, because the gold exceeds the stone or earth in weight. Next come all gold ores of which each one hundred librae contains more than three unciae of gold[7]; for although but a small proportion of gold is found in the earth or stone, yet it equals in value other metals of greater weight.[8] All other gold ores are considered poor, because the earth or stone too far outweighs the gold. A vein which contains a larger proportion of silver than of gold is rarely found to be a rich one. Earth, whether it be dry or wet, rarely abounds in gold; but in dry earth there is more often found a greater quantity of gold, especially if it has the appearance of having been melted in a furnace, and if it is not lacking in scales resembling mica. The solidified juices, azure, chrysocolla, orpiment, and realgar, also frequently contain gold. Likewise native or rudis gold is found sometimes in large, and sometimes in small quantities in quartz, schist, marble, and also in stone which easily melts in fire of the second degree, and which is sometimes so porous that it seems completely decomposed. Lastly, gold is found in pyrites, though rarely in large quantities.

When considering silver ores other than native silver, those ores are classified as rich, of which each one hundred librae contains more than three librae of silver. This quality comprises rudis silver, whether silver glance or ruby silver, or whether white, or black, or grey, or purple, or yellow, or liver-coloured, or any other. Sometimes quartz, schist, or marble is of this quality also, if much native or rudis silver adheres to it. But that ore is considered of poor quality if three librae of silver at the utmost are found in each one hundred librae of it[9]. Silver ore usually contains a greater quantity than this, because Nature bestows quantity in place of quality; such ore is mixed with all kinds of earth and stone compounds, except the various kinds of rudis silver; especially with pyrites, cadmia metallica fossilis, galena, stibium, and others.

As regards other kinds of metal, although some rich ores are found, still, unless the veins contain a large quantity of ore, it is very rarely worth while to dig them. The Indians and some other races do search for gems in veins hidden deep in the earth, but more often they are noticed from their clearness, or rather their brilliancy, when metals are mined. When they outcrop, we follow veins of marble by mining in the same way as is done with rock or building-stones when we come upon them. But gems, properly so called, though they sometimes have veins of their own, are still for the most part found in mines and rock quarries, as the lodestone in iron mines, the emery in silver mines, the lapis judaicus, trochites, and the like in stone quarries where the diggers, at the bidding of the owners, usually collect them from the seams in the rocks.[10] Nor does the miner neglect the digging of "extraordinary earths,"[11] whether they are found in gold mines, silver mines, or other mines; nor do other miners neglect them if they are found in stone quarries, or in their own veins; their value is usually indicated by their taste. Nor, lastly, does the miner fail to give attention to the solidified juices which are found in metallic veins, as well as in their own veins, from which he collects and gathers them. But I will say no more on these matters, because I have explained more fully all the metals and mineral substances in the books “De Natura Fossilium.”

But I will return to the indications. If we come upon earth which is like lute, in which there are particles of any sort of metal, native or rudis, the best possible indication of a vein is given to miners, for the metallic material from which the particles have become detached is necessarily close by. But if this kind of earth is found absolutely devoid of all metallic material, but fatty, and of white, green, blue, and similar colours, they must not abandon the work that has been started. Miners have other indications in the veins and stringers, which I have described already, and in the rocks, about which I will speak a little later. If the miner comes across other dry earths which contain native or rudis metal, that is a good indication; if he comes across yellow, red, black, or some other “extraordinary” earth, though it is devoid of mineral, it is not a bad indication. Chrysocolla, or azure, or verdigris, or orpiment, or realgar, when they are found, are counted among the good indications. Further, where underground springs throw up metal we ought to continue the digging we have begun, for this points to the particles having been detached from the main mass like a fragment from a body. In the same way the thin scales of any metal adhering to stone or rock are counted among the good indications. Next, if the veins which are composed partly of quartz, partly of clayey or dry earth, descend one and all into the depths of the earth together, with their stringers, there is good hope of metal being found; but if the stringers afterward do not appear, or little metallic material is met with, the digging should not be given up until there is nothing remaining. Dark or black or horn or liver-coloured quartz is usually a good sign; white is sometimes good, sometimes no sign at all. But calc–spar, showing itself in a vena profunda, if it disappears a little lower down is not a good indication; for it did not belong to the vein proper, but to some stringer. Those kinds of stone which easily melt in fire, especially if they are translucent (fluorspar?), must be counted among the medium indications, for if other good indications are present they are good, but if no good indications are present, they give no useful significance. In the same way we ought to form our judgment with regard to gems. Veins which at the hangingwall and footwall have horn-coloured quartz or marble, but in the middle clayey earth, give some hope; likewise those give hope in which the hangingwall or footwall shows iron-rust coloured earth, and in the middle greasy and sticky earth; also there is hope for those which have at the hanging or footwall that kind of earth which we call “soldiers' earth,” and in the middle black earth or earth which looks as if burnt. The special indication of gold is orpiment; of silver is bismuth and stibium; of copper is verdigris, melanteria, sory, chalcitis, misy, and vitriol; of tin is the large pure black stones of which the tin itself is made, and a material they dig up resembling litharge; of iron, iron rust. Gold and copper are equally indicated by chrysocolla and azure; silver and lead, by the lead. But, though miners rightly call bismuth “the roof of silver,” and though copper pyrites is the common parent of vitriol and melanteria, still these sometimes have their own peculiar minerals, just as have orpiment and stibium.

Now, just as certain vein materials give miners a favourable indication, so also do the rocks through which the canales of the veins wind their way, for sand discovered in a mine is reckoned among the good indications, especially if it is very fine. In the same way schist, when it is of a bluish or blackish colour, and also limestone, of whatever colour it may be, is a good sign for a silver vein. There is a rock of another kind that is a good sign; in it are scattered tiny black stones from which tin is smelted; especially when the whole space between the veins is composed of this kind of rock. Very often indeed, this good kind of rock in conjunction with valuable stringers contains within its folds the canales of mineral bearing veins: if it descends vertically into the earth, the benefit belongs to that mine in which it is seen first of all; if inclined, it benefits the other neighbouring mines[12]. As a result the miner who is not ignorant of geometry can calculate from the other mines the depth at which the canales of a vein bearing rich metal will wind its way through the rock into his mine. So much for these matters.

I now come to the mode of working, which is varied and complex, for in some places they dig crumbling ore, in others hard ore, in others a harder ore, and in others the hardest kind of ore. In the same way, in some places the hangingwall rock is soft and fragile, in others hard, in others harder, and in still others of the hardest sort. I call that ore “crumbling” which is composed of earth, and of soft solidified juices; that ore “hard” which is composed of metallic minerals and moderately hard stones, such as for the most part are those which easily melt in a fire of the first and second orders, like lead and similar materials. I call that ore “harder” when with those I have already mentioned are combined various sorts of quartz, or stones which easily melt in fire of the third degree, or pyrites, or cadmia, or very hard marble. I call that ore hardest, which is composed throughout the whole vein of these hard stones and compounds. The hanging or footwalls of a vein are hard, when composed of rock in which there are few stringers or seams; harder, in which they are fewer; hardest, in which they are fewest or none at all. When these are absent, the rock is quite devoid of water which softens it. But the hardest rock of the hanging or footwall, however, is seldom as hard as the harder class of ore.

Miners dig out crumbling ore with the pick alone. When the metal has not yet shown itself, they do not discriminate between the hangingwall and the veins; when it has once been found, they work with the utmost care. For first of all they tear away the hangingwall rock separately from the vein, afterward with a pick they dislodge the crumbling vein from the footwall into a dish placed underneath to prevent any of the metal from falling to the ground. They break a hard vein loose from the footwall by blows with a hammer upon the first kind of iron tool[13], all of which are designated by appropriate names, and with the same tools they hew away the hard hanging- wall rock. They hew out the hangingwall rock in advance more frequently, the rock of the footwall more rarely; and indeed, when the rock of the footwall resists iron tools, the rock of the hangingwall certainly cannot be broken unless it is allowable to shatter it by fire. With regard to the harder veins which are tractable to iron tools, and likewise with regard to the harder and hardest kind of hangingwall rock, they generally attack them with more powerful iron tools, in fact, with the fourth kind of iron tool, which are called by their appropriate names; but if these are not ready to hand, they use two or three iron tools of the first kind together. As for the hardest kind of metal-bearing vein, which in a measure resists iron tools, if the owners of the neighbouring mines give them permission, they break it with fires. But if these owners refuse them permission, then first of all they hew out the rock of the hangingwall, or of the footwall if it be less hard; then they place timbers set in hitches in the hanging or footwall, a little above the vein, and from the front and upper part, where the vein is seen to be seamed with small cracks, they drive into one of the little cracks one of the iron tools which I have mentioned; then in each fracture they place four thin iron blocks, and in order to hold them more firmly, if necessary, they place as many thin iron plates back to back; next they place thinner iron plates between each two iron blocks, and strike and drive them by turns with hammers, whereby the vein rings with a shrill sound; and the moment when it begins to be detached from the hangingwall or footwall rock, a tearing sound is heard. As soon as this grows distinct the miners hastily flee away; then a great crash is heard as the vein is broken and' torn, and falls down. By this method they throw down a portion of a vein weigh- ing a hundred pounds more or less. But if the miners by any other method hew the hardest kind of vein which is rich in metal, there remain certain cone-shaped portions which can be cut out afterward only with difficulty. As for this knob of hard ore, if it is devoid of metal, or if they are not allowed to apply fire to it, they proceed round it by digging to the right or left, because it cannot be broken into by iron wedges without great expense. Meantime, while the workmen are carrying out the task they have undertaken, the depths of the earth often resound with sweet singing, whereby they lighten a toil which is of the severest kind and full of the greatest dangers.

As I have just said, fire shatters the hardest rocks, but the method of its application is not simple[14] . For if a vein held in the rocks cannot be hewn out because of the hardness or other difficulty, and the drift or tunnel is low, a heap of dried logs is placed against the rock and fired; if the drift or tunnel is high, two heaps are necessary, of which one is placed above the other, and both burn until the fire has consumed them. This force does not generally soften a large portion of the vein, but only some of the surface. When the rock in the hanging or footwall can be worked by the iron tools and the vein is so hard that it is not tractable to the same tools, then the walls are hollowed out; if this be in the end of the drift or tunnel or above or below, the vein is then broken by fire, but not by the same method; for if the hollow is wide, as many logs are piled into it as possible, but if narrow, only a few. By the one method the greater fire separates the vein more completely from the footwall or sometimes from the hangingwall, and by the other, the smaller fire breaks away less of the vein from the rock, because in that case the fire is confined and kept in check by portions of the rock which surround the wood held in such a narrow excavation. Further, if the excavation is low, only one pile of logs is placed in it, if high, there are two, one placed above the other, by which plan the lower bundle being kindled sets alight the upper one; and the fire being driven by the draught into the vein, separates it from the rock which, however hard it may be, often becomes so softened as to be the most easily breakable of all. Applying this principle, Hannibal, the Carthaginian General, imitating the Spanish miners, overcame the hardness of the Alps by the use of vinegar and fire. Even if a vein is a very wide one, as tin veins usually are, miners excavate into the small streaks, and into those hollows they put dry wood and place amongst them at frequent intervals sticks, all sides of which are shaved down fanshaped, which easily take light, and when once they have taken fire communicate it to the other bundles of wood, which easily ignite.

A—kindled logs. B—sticks shaved down fan-shaped. C—tunnel.

While the heated veins and rock are giving forth a foetid vapour and the shafts or tunnels are emitting fumes, the miners and other workmen do not go down in the mines lest the stench affect their health or actually kill them, as I will explain in greater detail when I come to speak of the evils which affect miners. The Bergmeister, in order to prevent workmen from being suffocated, gives no one permission to break veins or rock by fire in shafts or tunnels where it is possible for the poisonous vapour and smoke to permeate the veins or stringers and pass through into the neighbouring mines, which have no hard veins or rock. As for that part of a vein or the surface of the rock which the fire has separated from the remaining mass, if it is overhead, the miners dislodge it with a crowbar, or if it still has some degree of hardness, they thrust a smaller crowbar into the cracks and so break it down, but if it is on the sides they break it with hammers. Thus broken off, the rock tumbles down; or if it still remains, they break it off with picks. Rock and earth on the one hand, and metal and ore on the other, are filled into buckets separately and drawn up to the open air or to the nearest tunnel. If the shaft is not deep, the buckets are drawn up by a machine turned by men; if it is deep, they are drawn by machines turned by horses.

It often happens that a rush of water or sometimes stagnant air hinders the mining; for this reason miners pay the greatest attention to these matters, just as much as to digging, or they should do so. The water of the veins and stringers and especially of vacant workings, must be drained out through the shafts and tunnels. Air, indeed, becomes stagnant both in tunnels and in shafts; in a deep shaft, if it be by itself, this occurs if it is neither reached by a tunnel nor connected by a drift with another shaft; this occurs in a tunnel if it has been driven too far into a mountain and no shaft has yet been sunk deep enough to meet it; in neither case can the air move or circulate. For this reason the vapours become heavy and resemble mist, and they smell of mouldiness, like a vault or some underground chamber which has been completely closed for many years. This suffices to prevent miners from continuing their work for long in these places, even if the mine is full of silver or gold, or if they do continue, they cannot breathe freely and they have headaches; this more often happens if they work in these places in great numbers, and bring many lamps, which then supply them with a feeble light, because the foul air from both lamps and men make the vapours still more heavy.

A small quantity of water is drawn from the shafts by machines of different kinds which men turn or work. If so great a quantity has flowed into one shaft as greatly to impede mining, another shaft is sunk some fathoms distant from the first, and thus in one of them work and labour are carried on without hindrance, and the water is drained into the other, which is sunk lower than the level of the water in the first one; then by these machines or by those worked by horses, the water is drawn up into the drain and flows out of the shaft-house or the mouth of the nearest tunnel. But when into the shaft of one mine, which is sunk more deeply, there flows all the water of all the neighbouring mines, not only from that vein in which the shaft is sunk, but also from other veins, then it becomes necessary for a large sump to be made to collect the water; from this sump the water is drained by machines which draw it through pipes, or by ox-hides, about which I will say more in the next book. The water which pours into the tunnels from the veins and stringers and seams in the rocks is carried away in the drains.

Air is driven into the extremities of deep shafts and long tunnels by powerful blowing machines, as I will explain in the following book, which will deal with these machines also. The outer air flows spontaneously into the caverns of the earth, and when it can pass through them comes out again. This, however, comes about in different ways, for in spring and summer it flows into the deeper shafts, traverses the tunnels or drifts, and finds its way out of the shallower shafts; similarly at the same season it pours into the lowest tunnel and, meeting a shaft in its course, turns aside to a higher tunnel and passes out therefrom; but in autumn and winter, on the other hand, it enters the upper tunnel or shaft and comes out at the deeper ones. This change in the flow of air currents occurs in temperate regions at the beginning of spring and the end of autumn, but in cold regions at the end of spring and the beginning of autumn. But at each period, before the air regularly assumes its own accustomed course, generally for a space of fourteen days it undergoes frequent variations, now blowing into an upper shaft or tunnel, now into a lower one. But enough of this, let us now proceed to what remains.

There are two kinds of shafts, one of the depth already described, of which kind there are usually several in one mine; especially if the mine is entered by a tunnel and is metal-bearing. For when the first tunnel is connected with the first shaft, two new shafts are sunk; or if the inrush of water hinders sinking, sometimes three are sunk; so that one may take the place of a sump and the work of sinking which has been begun may be continued by means of the remaining two shafts; the same is done in the case of the second tunnel and the third, or even the fourth, if so many are driven into a mountain. The second kind of shaft is very deep, sometimes as much as sixty, eighty, or one hundred fathoms. These shafts continue vertically toward the depths of the earth, and by means of a hauling-rope the broken rock and metalliferous ores are drawn out of the mine; for which reason miners call them vertical shafts. Over these shafts are erected machines by which water is extracted; when they are above ground the machines are usually worked by horses, but when they are in tunnels, other kinds are used which are turned by water-power. Such are the shafts which are sunk when a vein is rich in metal.

Now shafts, of whatever kind they may be, are supported in various ways. If the vein is hard, and also the hanging and footwall rock, the shaft does not require much timbering, but timbers are placed at intervals, one end of each of which is fixed in a hitch cut into the rock of the hangingwall and the other fixed into a hitch cut in the footwall. To these timbers are fixed small timbers along the footwall, to which are fastened the lagging and ladders. The lagging is also fixed to the timbers, both to those which screen off the shaft on the ends from the vein, and to those which screen off the rest of the shaft from that part in which the ladders are placed. The lagging on the sides of the shaft confine the vein, so as to prevent fragments of it which have become loosened by water from dropping into the shaft and terrifying, or injuring, or knocking off the miners and other workmen who are going up or down the ladders from one part of the mine to another. For the same reason, the lagging between the ladders and the haulage-way on the other hand, confine and shut off from the ladders the fragments of rock which fall from the buckets or baskets while they are being drawn up; moreover, they make the arduous and difficult descent and ascent to appear less terrible, and in fact to be less dangerous. If a vein is soft and the rock of the hanging and footwalls is weak, a closer structure is necessary; for this purpose timbers are joined together in rectangular shapes and placed one after the other without a break. These

A—wall plates. B—dividers. C—Long End Posts. D—end plates.

When a very deep shaft, whether vertical or inclined, is supported by joined timbers, then, since they are sometimes of bad material and a fall is threatened, for the sake of greater firmness three or four pairs of strong end posts are placed between these, one pair on the hangingwall side, the other on the footwall side. To prevent them from falling out of position and to make them firm and substantial, they are supported by frequent end plates, and in order that these may be more securely fixed they are mortised into the posts. Further, in whatever way the shaft may be timbered, dividers are placed upon the wall plates, and to these is fixed lagging, and this marks off and separates the ladder-way from the remaining part of the shaft. If a vertical shaft is a very deep one, planks are laid upon the timbers by the side of the ladders and fixed on to the timbers, in order that the men who are going up or down may sit or stand upon them and rest when they are tired. To prevent danger to the shovellers from rocks which, after being drawn up from so deep a shaft fall down again, a little above the bottom of the shaft small rough sticks are placed close together on the timbers, in such a way as to cover the whole space of the shaft except the ladder-way. A hole, however, is left in this structure near the footwall, which is kept open so that there may be one opening to the shaft from the bottom, that the buckets full of the materials which have been dug out may be drawn from the shaft through it by machines, and may be returned to the same place again empty; and so the shovellers and other workmen, as it were hiding beneath this structure, remain perfectly safe in the shaft.

In mines on one vein there are driven one, two, or sometimes three or more tunnels, always one above the other. If the vein is solid and hard, and likewise the hanging and footwall rock, no part of the tunnel needs support, beyond that which is required at the mouth, because at that spot there is not yet solid rock; if the vein is soft, and the hanging and footwall rock are likewise soft, the tunnel requires frequent strong timbering, which is provided in the following way. First, two dressed posts are erected and set into the tunnel floor, which is dug out a little; these are of medium thickness, and high enough that their ends, which are cut square, almost touch the top of the tunnel; then upon them is placed a smaller dressed cap, which is mortised into the heads of the posts; at the bottom, other small timbers, whose ends are similarly squared, are mortised into the posts. At each interval of one and a half fathoms, one of these sets is erected; each one of these the miners call a “little doorway,” because it opens a certain amount of passage way; and indeed, when necessity requires it, doors are fixed to the timbers of each little doorway so that it can be closed. Then lagging of planks or of poles is placed upon the caps lengthwise, so as to reach from one set of timbers to another, and is laid along the sides, in case some portion of the body of the mountain may fall, and by its bulk impede passage or crush persons coming in or out. Moreover, to make the timbers remain stationary, wooden pegs are driven between them and the sides of the tunnel. Lastly, if rock or earth are carried out in wheelbarrows, planks joined together are laid upon the sills; if the rock is hauled out in trucks, then two timbers three-quarters of a foot thick and wide are laid on the sills, and, where they join, these are usually hollowed out so that in the hollow, as in a road, the iron pin of the truck may be pushed along; indeed, because of this pin in the groove, the truck does not leave the worn track to the left or right. Beneath the sills are the drains through which the water flows away.

A—posts. B—caps. C—sills. D—doors. E—lagging. F—drains.

Miners timber drifts in the same way as tunnels. These do not, however, require sill-pieces, or drains; for the broken rock is not hauled very far, nor does the water have far to flow. If the vein above is metal-bearing, as it sometimes is for a distance of several fathoms, then from the upper part of tunnels or even drifts that have already been driven, other drifts are driven again and again until that part of the vein is reached which does not yield metal. The timbering of these openings is done as follows: stulls are set at intervals into hitches in the hanging and footwall, and upon them smooth poles are laid continuously; and that they may be able to bear the weight, the stulls are generally a foot and a half thick. After the ore has been taken out and the mining of the vein is being done elsewhere, the rock then broken, especially if it cannot be taken away without great difficulty, is thrown into these openings among the timber, and the carriers of the ore are saved toil, and the owners save half the expense. This then, generally speaking, is the method by which everything relating to the timbering of shafts, tunnels, and drifts is carried out.

All that I have hitherto written is in part peculiar to venae profundae, and in part common to all kinds of veins; of what follows, part is specially applicable to venae dilatatae, part to venae cumulatae. But first I will describe how venae dilatatae should be mined. Where torrents, rivers, or streams have by inundations washed away part of the slope of a mountain or a hill, and have disclosed a vena dilatata, a tunnel should be driven first straight and narrow, and then wider, for nearly all the vein should be hewn away; and when this tunnel has been driven further, a shaft which supplies air should be sunk in the mountain or hill, and through it from time to time the ore, earth, and rock can be drawn up at less expense than if they be drawn out through the very great length of the tunnel; and even in those places to which the tunnel does not yet reach, miners dig shafts in order to open a vena dilatata which they conjecture must lie beneath the soil. In this way, when the upper layers are removed, they dig through rock sometimes of one kind and colour, sometimes of one kind but different colours, sometimes of different kinds but of one colour, and, lastly, of different kinds and different colours. The thickness of rock, both of each single stratum and of all combined, is uncertain, for the whole of the strata are in some places twenty fathoms deep, in others more than fifty; individual strata are in some places half a foot thick; in others, one, two, or more feet; in others, one, two, three, or more fathoms. For example, in those districts which lie at the foot of the Harz mountains, there are many different coloured strata, covering a copper vena dilatata.

When the soil has been stripped, first of all is disclosed a stratum which is red, but of a dull shade and of a thickness of twenty, thirty, or five and thirty fathoms. Then there is another stratum, also red, but of a light shade, which has usually a thickness of about two fathoms. Beneath this is a stratum of ash-coloured clay nearly a fathom thick, which, although it is not metalliferous, is reckoned a vein. Then follows a third stratum, which is ashy, and about three fathoms thick. Beneath this lies a vein of ashes to the thickness of five fathoms, and these ashes are mixed with rock of the same colour. Joined to the last, and underneath, comes a stratum, the fourth in number, dark in colour and a foot thick. Under this comes the fifth stratum, of a pale or yellowish colour, two feet thick; neath which is the sixth stratum, likewise dark, but rough and three feet thick. Afterward occurs the seventh stratum, likewise of dark colour, but still darker than the last, and two feet thick. This is followed by an eighth stratum, ashy, rough, and a foot thick. This kind, as also the others, is sometimes distinguished by stringers of the stone which easily melts in fire of the second order. Beneath this is another ashy rock, light in weight, and five feet thick. Next to this comes a lighter ash-coloured one, a foot thick; beneath this lies the eleventh stratum, which is dark and very much like the seventh, and two feet thick. Below the last is a twelfth stratum of a whitish colour arid soft, also two feet thick; the weight of this rests on a thirteenth stratum, ashy and one foot thick, whose weight is in turn supported by a fourteenth stratum, which is blackish and half a foot thick. There follows this, another stratum of black colour, likewise half a foot thick, which is again followed by a sixteenth stratum still blacker in colour, whose thickness is also the same. Beneath this, and last of all, lies the cupriferous stratum, black coloured and schistose, in which there sometimes glitter scales of gold-coloured pyrites in the very thin sheets, which, as I said elsewhere, often take the forms of various living things.[15]

The miners mine out a vena dilatata laterally and longitudinally by driving a low tunnel in it, and if the nature of the work and place permit, they sink also a shaft in order to discover whether there is a second vein beneath the first one; for sometimes beneath it there are two, three, or more similar metal-bearing veins, and these are excavated in the same way laterally and longitudinally. They generally mine venæ dilatatæ lying down; and to avoid wearing away their clothes and injuring their left shoulders they usually bind on themselves small wooden cradles. For this reason, this particular class of miners, in order to use their iron tools, are obliged to bend their necks to the left, not infrequently having them twisted. Now these veins also sometimes divide, and where these parts re-unite, ore of a richer and a better quality is generally found; the same thing occurs where the stringers, of which they are not altogether devoid, join with them, or cut them crosswise, or divide them obliquely. To prevent a mountain or hill, which has in this way been undermined, from subsiding by its weight, either some natural pillars and arches are left, on which the pressure rests as on a foundation, or timbering is done for support. Moreover, the materials which are dug out and which are devoid of metal are removed in bowls, and are thrown back, thus once more filling the caverns.

Next, as to venæ cumulatæ. These are dug by a somewhat different method, for when one of these shows some metal at the top of the ground, first of all one shaft is sunk; then, if it is worth while, around this one many shafts are sunk and tunnels are driven into the mountain. If a torrent or spring has torn fragments of metal from such a vein, a tunnel is first driven into the mountain or hill for the purpose of searching for the ore; then when it is found, a vertical shaft is sunk in it. Since the whole mountain, or more especially the whole hill, is undermined, seeing that the whole of it is composed of ore, it is necessary to leave the natural pillars and arches, or the place is timbered. But sometimes when a vein is very hard it is broken by fire, whereby it happens that the soft pillars break up, or the timbers are burnt away, and the mountain by its great weight sinks into itself, and then the shaft buildings are swallowed up in the great subsidence. Therefore, about a vena cumulata it is advisable to sink some shafts which are not subject to this kind of ruin, through which the materials that are excavated may be carried out, not only while the pillars and underpinnings still remain whole and solid, but also after the supports have been destroyed by fire and have fallen. Since ore which has thus fallen must necessarily be broken by fire, new shafts through which the smoke can escape must be sunk in the abyss. At those places where stringers intersect, richer ore is generally obtained from the mine; these stringers, in the case of tin mines, sometimes have in them black stones the size of a walnut. If such a vein is found in a plain, as not infrequently happens in the case of iron, many shafts are sunk, because they cannot be sunk very deep. The work is carried on by this method because the miners cannot drive a tunnel into a level plain of this kind.

There remain the stringers in which gold alone is sometimes found, in the vicinity of rivers and streams, or in swamps. If upon the soil being removed, many of these are found, composed of earth somewhat baked and burnt, as may sometimes be seen in clay pits, there is some hope that gold may be obtained from them, especially if several join together. But the very point of junction must be pierced, and the length and width searched for ore, and in these places very deep shafts cannot be sunk.

I have completed one part of this book, and now come to the other, in which I will deal with the art of surveying. Miners measure the solid mass of the mountains in order that the owners may lay out their plans, and that their workmen may not encroach on other people's possessions. The surveyor either measures the interval not yet wholly dug through, which lies between the mouth of a tunnel and a shaft to be sunk to that depth, or between the mouth of a shaft and the tunnel to be driven to that spot which lies under the shaft, or between both, if the tunnel is neither so long as to reach to the shaft, nor the shaft so deep as to reach to the tunnel; and thus on both sides work is still to be done. Or in some cases, within the tunnels and drifts, are to be fixed the boundaries of the meers, just as the Bergmeister has determined the boundaries of the same meers above ground.[16]

Each method of surveying depends on the measuring of triangles. A small triangle should be laid out, and from it calculations must be made regarding a larger one. Most particular care must be taken that we do not deviate at all from a correct measuring; for if, at the beginning, we are drawn by carelessness into a slight error, this at the end will produce great errors. Now these triangles are of many shapes, since shafts differ among themselves and are not all sunk by one and the same method into the depths of the earth, nor do the slopes of all mountains come down to the valley or plain in the same manner. For if a shaft is vertical, there is a triangle with a right angle, which the Greeks call ὀρθογώνιον and this, according to the inequalities of the mountain slope, has either two equal sides or three unequal sides. The Greeks call the former τρίγωνον ἰσοσκελές the latter σκαληνόν for a right angle triangle cannot have three equal sides. If a shaft is inclined and sunk in the same vein in which the tunnel is driven, a triangle is likewise made with a right angle, and this again, according to the various inequalities of the mountain slope, has either two equal or three unequal sides. But if a shaft is inclined and is sunk in one vein, and a tunnel is driven in another vein, then a triangle comes into existence which has either an obtuse angle or all acute angles. The former the Greeks call ἀμβλυγώνιον, the latter . That triangle which has an obtuse angle cannot have three equal sides, but in accordance with the different mountain slopes has either two equal sides or three unequal sides. That triangle which has all acute angles in accordance with the different mountain slopes has either three equal sides, which the Greeks call τρίγωνον ισόλευρον or two equal sides or three unequal sides.

The surveyor, as I said, employs his art when the owners of the mines desire to know how many fathoms of the intervening ground require to be dug; when a tunnel is being driven toward a shaft and does not yet reach it; or when the shaft has not yet been sunk to the depth of the bottom of the tunnel which is under it; or when neither the tunnel reaches to that point, nor has the shaft been sunk to it. It is of importance that miners should know how many fathoms remain from the tunnel to the shaft, or from the shaft to the tunnel, in order to calculate the expenditure; and in order that the owners of a metal-bearing mine may hasten the sinking of a shaft and the excavation of the metal, before the tunnel reaches that point and the tunnel owners excavate part of the metal by any right of their own; and on the other hand, it is important that the owners of a tunnel may similarly hasten their driving before a shaft can be sunk to the depth of a tunnel, so that they may excavate the metal to which they will have a right.

The surveyor, first of all, if the beams of the shaft-house do not give him the opportunity, sets a pair of forked posts by the sides of the shaft in such a manner that a pole may be laid across them. Next, from the pole he lets down into the shaft a cord with a weight attached to it. Then he stretches a second cord, attached to the upper end of the first cord, right down along the slope of the mountain to the bottom of the mouth of the tunnel, and fixes it to the ground. Next, from the same pole not far from the first cord, he lets down a third cord, similarly weighted, so that it may intersect the second cord, which descends obliquely. Then, starting from that point where the third cord cuts the second cord which descends obliquely to the mouth of the tunnel, he measures the second cord upward to where it reaches the end of A—Upright forked posts. B—Pole over the posts. C—Shaft. D—First cord. E—Weight of first cord. F—Second cord. G—Same fixed ground. H—Head of first cord. I—Mouth of tunnel. K—Third cord. L—Weight of third cord. M—First side minor triangle. N—Second side minor triangle. O—Third side minor triangle. P—The minor triangle.

the first cord, and makes a note of this first side of the minor triangle[17]. Afterward, starting again from that point where the third cord intersects the second cord, he measures the straight space which lies between that point and the opposite point on the first cord, and hi that way forms the minor triangle, and he notes this second side of the minor triangle in the same way as before. Then, if it is necessary, from the angle formed by the first cord and the second side of the minor triangle, he measures upward to the end of the first cord and also makes a note of this third side of the minor triangle. The third side of the minor triangle, if the shaft is vertical or inclined and is sunk on the same vein in which the tunnel is driven, will necessarily be the same length as the third cord above the point where it intersects the second cord; and so, as often as the first side of the minor triangle is contained in the length of the whole cord which descends obliquely, so many times the length of the second side of the minor triangle indicates the distance between the mouth of the tunnel and the point to which the shaft must be sunk; and similarly, so many times the length of the third side of the minor triangle gives the distance between the mouth of the shaft and the bottom of the tunnel.

When there is a level bench on the mountain slope, the surveyor first measures across this with a measuring-rod; then at the edges of this bench he sets up forked posts, and applies the principle of the triangle to the two sloping parts of the mountain; and to the fathoms which are the length of that part of the tunnel determined by the triangles, he adds the number of fathoms which are the width of the bench. But if sometimes the mountain side stands up, so that a cord cannot run down from the shaft to the mouth of the tunnel, or, on the other hand, cannot run up from the mouth of the tunnel to the shaft, and, therefore, one cannot connect them in a straight line, the surveyor, in order to fix an accurate triangle, measures the mountain; and going downward he substitutes for the first part of the cord a pole one fathom long, and for the second part a pole half a fathom long. Going upward, on the contrary, for the first part of the cord he substitutes a pole half a fathom long, and for the next part, one a whole fathom long; then where he requires to fix his triangle he adds a straight line to these angles.

To make this system of measuring clear and more explicit, I will proceed by describing each separate kind of triangle. When a shaft is vertical or inclined, and is sunk in the same vein on which the tunnel is driven, there is created, as I said, a triangle containing a right angle. Now if the minor triangle has the two sides equal, which, in accordance with the numbering used by surveyors, are the second and third sides, then the second and third sides of the major triangle will be equal; and so also the intervening distances will be equal which lie between the mouth of the tunnel and the bottom of the shaft, and which lie between the mouth of the shaft and the bottom of the tunnel. For example, if the first side of the minor triangle is seven feet long and the second and likewise the third sides are five feet, and the length shown by the cord for the side of the major triangle is 101 times seven feet, that is 117 fathoms and five feet, then the intervening space, of course, whether the whole of it has been already driven through or has yet to be driven, will be one hundred times five feet, which makes eighty-three fathoms and two feet. Anyone with this example of proportions will be able to construct the major and minor triangles in the same way as I have done, if there be the necessary upright posts and cross-beams. When a shaft is vertical the triangle is absolutely upright; when it is inclined and is sunk on the same vein in which the tunnel is driven, it is inclined toward one side.

Therefore, if a tunnel has been driven into the mountain for sixty fathoms, there remains a space of ground to be penetrated twenty-three fathoms and two feet long; for five feet of the second side of the major triangle, which lies above the mouth of the shaft and corresponds with the first side of the minor triangle, must not be added. Therefore, if the shaft has been sunk in the middle of the head meer, a tunnel sixty fathoms long will reach to the boundary of the meer only when the tunnel has been extended a further two fathoms and two feet; but if the shaft is located in the middle of an ordinary meer, then the boundary will be reached when the tunnel has been driven a further length of nine fathoms and two feet. Since a tunnel, for every one hundred fathoms of length, rises in grade one fathom, or at all events, ought to rise as it proceeds toward the shaft, one more fathom must always be taken from the depth allowed to the shaft, and one added to the length allowed to the tunnel. Proportionately, because a tunnel fifty fathoms long is raised half a fathom, this amount must be taken from the depth of the shaft and added to the length of the tunnel. In the same way if a tunnel is one hundred or fifty fathoms shorter or longer, the same proportion also must be taken from the depth of the one and added to the length of the other. For this reason, in the case mentioned above, half a fathom and a little more must be added to the distance to be driven through, so that there remain twenty-three fathoms, five feet, two palms, one and a half digits and a fifth of a digit; that is, if even the minutest proportions are carried out; and surveyors do not neglect these without good cause. Similarly, if the shaft is seventy fathoms deep, in order that it may reach to the bottom of the tunnel, it still must be sunk a further depth of thirteen fathoms and two feet, or rather twelve fathoms and a half, one foot, two digits, and four-fifths of half a digit. And in this instance five feet must be deducted from the reckoning, because these five feet complete the third side of the minor triangle, which is above the mouth of the shaft, and from its depth there must be deducted half a fathom, two palms, one and a half digits and the fifth part of half a digit. But if the tunnel has been driven to a point where it is under the shaft, then to reach the roof of the tunnel the shaft must still be sunk a depth of eleven fathoms, two and a half feet, one palm, two digits, and four-fifths of half a digit.

If a minor triangle is produced of the kind having three unequal sides, then the sides of the greater triangle cannot be equal; that is, if the first side of the minor triangle is eight feet long, the second six feet long, and the third five feet long, and the cord along the side of the greater triangle, not to go too far from the example just given, is one hundred and one times eight feet, that is, one hundred and thirty-four fathoms and four feet, the distance which lies between the mouth of the tunnel and the bottom of the shaft will occupy one hundred times six feet in length, that is, one hundred fathoms. The distance between the mouth of the shaft and the bottom of the tunnel is one hundred times five feet, that is, eighty-three fathoms and two feet. And so, if the tunnel is eighty-five fathoms long, the remainder to be driven into the mountain is fifteen fathoms long, and here, too, a correction in measurement must be taken from the depth of the shaft and added to the length of the tunnel; what this is precisely, I will pursue no further, since everyone having a small knowledge of arithmetic can work it out. If the shaft is sixty-seven fathoms deep, in order that it may reach the bottom of the tunnel, the further distance required to be sunk amounts to sixteen fathoms and two feet.

A triangle having a right angle and three unequal sides.

The surveyor employs this same method in measuring the mountain, whether the shaft and tunnel are on one and the same vein, whether the vein is vertical or inclined, or whether the shaft is on the principal vein and the tunnel on a transverse vein descending vertically to the depths of the earth; in the latter case the excavation is to be made where the transverse vein cuts the vertical vein. If the principal vein descends on an incline and the cross-vein descends vertically, then a minor triangle is created having one obtuse angle or all three angles acute. If the minor triangle has one angle obtuse and the two sides which are the second and third are equal, then the second and third sides of the major triangle will be equal, so that if the first side of the minor triangle is nine feet, the second, and likewise the third, will be five feet. Then the first side of the major triangle will be one hundred and one times nine feet, or one hundred and fifty-one and one-half fathoms, and each of the other sides of the major triangle will be one hundred times five feet, that is, eighty-three fathoms and two feet. But when the first shaft is inclined, generally speaking, it is not deep; but there are usually several, all inclined, and one always following the other. Therefore, if a tunnel is seventyseven fathoms long, it will reach to the middle of the bottom of a shaft when six fathoms and two feet further have been sunk. But if all such inclined shafts are seventy-six fathoms deep, in order that the last one may reach the bottom of the tunnel, a depth of seven fathoms and two feet remains to be sunk.

Triangle having an obtuse angle and two equal sides.

If a minor triangle is made which has an obtuse angle and three unequal sides, then again the sides of the large triangle cannot be equal. For example, if the first side of the minor triangle is six feet long, the second three feet, and the third four feet, and the cord along the side of the greater triangle one hundred and one times six feet, that is, one hundred and one fathoms, the distance between the mouth of the tunnel and the bottom of the last shaft will be a length one hundred times three feet, or fifty fathoms; but the depth that lies between the mouth of the first shaft and the bottom of the tunnel is one hundred times four feet, or sixty-six fathoms and four feet. Therefore, if a tunnel is forty-four fathoms long, the remaining distance to be driven is six fathoms. If the shafts are fifty-eight fathoms deep, the newest will touch the bottom of the tunnel when eight fathoms and four feet have been sunk.

Triangle having an obtuse angle and three unequal sides..

If a minor triangle is produced which has all its angles acute and its three sides equal, then necessarily the second and third sides of the minor triangle will be equal, and likewise the sides of the major triangle frequently referred to will be equal. Thus if each side of the minor triangle is six feet long, and the cord measurement for the side of the major triangle is one hundred and one times six feet, that is, one hundred and one fathoms, then both the distances to be dug will be one hundred fathoms. And thus if the tunnel is ninety fathoms long, it will reach the middle of the bottom of the last shaft when ten fathoms further have been driven. If the shafts are ninety-five fathoms deep, the last will reach the bottom of the tunnel when it is sunk a further depth of five fathoms.

A triangle having all its angles acute and its three sides equal.

If a triangle is made which has all its angles acute, but only two sides equal, namely, the first and third, then the second and third sides are not equal; therefore the distances to be dug cannot be equal. For example, if the first side of the minor triangle is six feet long, and the second is four feet, and the third is six feet, and the cord measurement for the side of the major triangle is one hundred and one times six feet, that is, one hundred and one fathoms, then the distance between the mouth of the tunnel and the bottom of the last shaft will be sixty-six fathoms and four feet. But the distance from the mouth of the first shaft to the bottom of the tunnel is one hundred fathoms.

So if the tunnel is sixty fathoms long, the remaining distance to be driven into the mountain is six fathoms and four feet. If the shaft is ninety-seven fathoms deep, the last one will reach the bottom of the tunnel when a further depth of three fathoms has been sunk.

Triangle having all its angles acute and two sides equal, a, b, unequal side c.

If a minor triangle is produced which has all its angles acute, but its three sides unequal, then again the distances to be dug cannot be equal.

For example, if the first side of the minor triangle is seven feet long, the second side is four feet, and the third side is six feet, and the cord measurement for the side of the major triangle is one hundred and one times seven feet or one hundred and seventeen fathoms and four feet, the distance between the mouth of the tunnel and the bottom of the last shaft will be four hundred feet or sixty-six fathoms, and the depth between the mouth of the first shaft and the bottom of the tunnel will be one hundred fathoms.

Therefore, if a tunnel is fifty fathoms long, it will reach the middle of the bottom of the newest shaft when it has been driven sixteen fathoms and four feet further. But if the shafts are then ninety-two fathoms deep, the last shaft will reach the bottom of the tunnel when it has been sunk a further eight fathoms.

A triangle having all its angles acute and its three sides unequal.

This is the method of the surveyor in measuring the mountain, if the principal vein descends inclined into the depths of the earth or the transverse vein is vertical. But if they are both inclined, the surveyor uses the same method, or he measures the slope of the mountain separately from the slope of the shaft. Next, if a transverse vein in which a tunnel is driven does not cut the principal vein in that spot where the shaft is sunk, then it is necessary for the starting point of the survey to be in the other shaft in which the transverse vein cuts the principal vein. But if there be no shaft on that spot where the outcrop of the transverse vein cuts the outcrop of the principal vein, then the surface of the ground which lies between the shafts must be measured, or that between the shaft and the place where the outcrop of the one vein intersects the outcrop of the other.

Some surveyors, although they use three cords, nevertheless ascertain only the length of a tunnel by that method of measuring, and determine the depth of a shaft by another method; that is, by the method by which cords are re-stretched on a level part of the mountain or in a valley, or in flat fields, and are measured again. Some, however, do not employ this method in surveying the depth of a shaft and the length of a tunnel, but use only two cords, a graduated hemicycle[18] and a rod half a fathom long. They suspend in the shaft one cord, fastened from the upper pole and weighted, just as the others do. Fastened to the upper end of this cord, they stretch another right down the slope of the mountain to the bottom of the mouth of the tunnel and fix it to the ground. Then to the upper part of this second cord they apply on its lower side the broad part of a hemicycle. This consists of half a circle, the outer margin of which is covered with wax, and within this are six semi-circular lines. From the waxed margin through the first semi-circular line, and reaching to the second, there proceed straight lines converging toward the centre of the hemicycle; these mark the middles of intervening spaces lying between other straight lines which extend to the fourth semi-circular line. But all lines whatsoever, from the waxed margin up to the fourth line, whether they go beyond it or not, correspond with the graduated lines which mark the minor spaces of a rod. Those which go beyond the fourth line correspond with the lines marking

A—waxed semicircle of the hemicycle. B—semicircular lines. C—straight lines. D—line measuring the half. E—line measuring the whole. F—tongue.

the major spaces on the rod, and those which proceed further, mark the middle of the intervening space which lies between the others. The straight lines, which run from the fifth to the sixth semi-circular line, show nothing further. Nor does the line which measures the half, show anything when it has already passed from the sixth straight line to the base of the hemicycle. When the hemicycle is applied to the cord, if its tongue indicates the sixth straight line which lies between the second and third semi-circular lines, the surveyor counts on the rod six lines which separate the minor spaces, and if the length of this portion of the rod be taken from the second cord, as many times as the cord itself is half-fathoms long, the remaining length of cord shows the distance the tunnel must be driven to reach under the shaft. But if he sees that the tongue has gone so far that it marks the sixth line between the fourth and fifth semi-circular lines, he counts six lines which separate the major spaces on the rod; and this entire space is deducted from the length of the second cord, as many times as the number of whole fathoms which the cord contains; and then, in like manner, the remaining length of cord shows us the distance the tunnel must be driven to reach under the shaft.[19]

Stretched cords: A—first cord. B—second cord. C—third cord. D—triangle.

Both these surveyors, as well as the others, in the first place make use of the haulage rope. These they measure by means of others made of linden bark, because the latter do not stretch at all, while the former become very slack. These cords they stretch on the surveyor's field, the first one to represent the parts of mountain slopes which descend obliquely. Then the second cord, which represents the length of the tunnel to be driven to reach the shaft, they place straight, in such a direction that one end of it can touch the lower end of the first cord; then they similarly lay the third cord straight, and in such a direction that its upper end may touch the upper end of the first cord, and its lower end the other extremity of the second cord, and thus a triangle is formed. This third cord is measured by the instrument with the index, to determine its relation to the perpendicular; and the length of this cord shows the depth of the shaft.

Some surveyors, to make their system of measuring the depth of a shaft more certain, use five stretched cords: the first one descending obliquely; two, that is to say the second and third, for ascertaining the length of the tunnel; two for the depth of the shaft; in which way they form a quadrangle divided into two equal triangles, and this tends to greater accuracy.

Stretched cords: A—first. B—second. B—third. C—fourth. C—fifth. D—quadrangle.

These systems of measuring the depth of a shaft and the length of a tunnel, are accurate when the vein and also the shaft or shafts go down to the tunnel vertically or inclined, in an uninterrupted course. The same is true when a tunnel runs straight on to a shaft. But when each of them bends now in this, now in that direction, if they have not been completely driven and sunk, no living man is clever enough to judge how far they are deflected from a straight course. But if the whole of either one of the two has been excavated its full distance, then we can estimate more easily the length of one, or the depth of the other; and so the location of the tunnel, which is below a newly-started shaft, is determined by a method of surveying which I will describe. First of all a tripod is fixed at the mouth of the tunnel, and likewise at the mouth of the shaft which has been started, or at the place where the shaft will be started. The tripod is made of three stakes fixed to the ground, a small rectangular board being placed upon the stakes and fixed to them, and on this is set a compass. Then from the lower tripod a weighted cord is let down perpendicularly to the earth, close to which cord a stake is fixed in the ground. To this stake another cord is tied and drawn straight into the tunnel to a point as far as it can go without being bent by the hangingwall or the footwall of the vein. Next, from the cord which hangs from the lower tripod, a third cord likewise fixed is brought straight up the sloping side of the mountain to the stake of the upper tripod, and fastened to it. In order that the measuring of the depth of the shaft may be more certain, the third cord should touch one and the same side of the cord hanging from the lower tripod which is touched by the second cord the one which is drawn into the tunnel. All this having been correctly carried out, the surveyor, when at length the cord which has been drawn straight into the tunnel is about to be bent by the hangingwall or footwall, places a plank in the bottom of the tunnel and on it sets the orbis, an instrument which has an indicator peculiar to itself. This instrument, although it also has waxed circles, differs from the other, which I have described in the third book. But by both these instruments, as well as by a rule and a square, he determines whether the stretched cords reach straight to the extreme end of the tunnel, or whether they sometimes reach straight, and are sometimes bent by the footwall or hangingwall. Each instrument is divided into parts, but the compass into twenty-four parts, the orbis into sixteen parts; for first of all it is divided into four principal parts, and then each of these is again divided into four. Both have waxed circles, but the compass has seven circles, and the orbis only five circles. These waxed circles the surveyor marks, whichever instrument he uses, and by the succession of these same marks he notes any change in the direction in which the cord extends. The orbis has an opening running from its outer edge as far as the centre, into which opening he puts an iron screw, to which he binds the second cord, and by screwing it into the plank, fixes it so that the orbis may be immovable. He takes care to prevent the second cord, and afterward the others which are put up, from being pulled off the screw, by employing a heavy iron, into an opening of which he fixes the head of the screw. In the case of the compass, since it has no opening, he merely places it by the side of the screw. That the instrument does not incline forward or backward, and in that way the measurement become a greater length than it should be, he sets upon the instrument a standing plummet level, the tongue of which, if the instrument is level, indicates no numbers, but the point from which the numbers start.

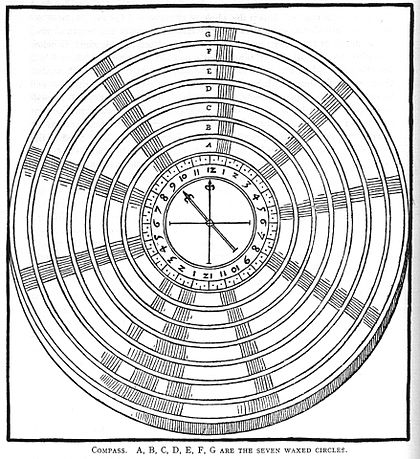

Compass. A, B, C, D, E, F, G are the seven waxed circles.

A, B, C, D, E Five waxed circles of the orbis. F Opening of same. G Screw. H Perforated iron.

A—Lines of the rod which separate minor spaces. B—Lines of the rod which separate major spaces.

such an angle as represents the slope of the mountain, so that its lower end may reach the end of the straight cord; then he stretches a third cord

A—Standing plummet level. B—Tongue. C—Level and tongue.

similarly straight and at such an angle, that with its upper end it may reach the upper end of the second cord, and with its lower end the last end of the first cord. The length of the third cord shows the depth of the shaft, as I said before, and at the same time that point on the tunnel to which the shaft will reach when it has been sunk.

If one or more shafts reach the tunnel through intermediate drifts and shafts, the surveyor, starting from the nearest which is open to the air, measures in a shorter time the depth of the shaft which requires to be sunk, than if he starts from the mouth of the tunnel. First of all he measures that space on the surface which lies between the shaft which has been sunk and the one which requires to be sunk. Then he measures the incline of all the shafts which it is necessary to measure, and the length of all the drifts with which they are in any way connected to the tunnel. Lastly, he measures part of the tunnel; and when all this is properly done, he demonstrates the depth of the shaft and the point in the tunnel to which the shaft will reach. But sometimes a very deep straight shaft requires to be sunk at the same place where there is a previous inclined shaft, and to the same depth, in order that loads may be raised and drawn straight up by machines. Those machines on the surface are turned by horses; those inside the earth, by the same means, and also by water-power. And so, if it becomes necessary to sink such a shaft, the surveyor first of all fixes an iron screw in the upper part of the old shaft, and from the screw he lets down a cord as far as the first angle, where again he fixes a screw, and again lets down the cord as far as the second angle; this he repeats again and again until the cord reaches to the bottom of the shaft. Then to each angle of the cord he applies a hemicycle, and marks the waxed semi-circle according to the lines which the tongue indicates, and designates it by a number, in case it should be moved; then he measures the separate parts of the cord with another cord made of linden bark. Afterward, when he has come back out of the shaft, he goes away and transfers the markings from the waxed semi-circle of the hemicycle to an orbis similarly waxed. Lastly, the cords are stretched on the surveyor's field, and he measures the angles, as the system of measuring by triangles requires, and ascertains which part of the footwall and which part of the hangingwall rock must be cut away in order that the shaft may descend straight. But if the surveyor is required to show the owners of the mine, the spot in a drift or a tunnel in which a shaft needs to be raised from the bottom upward, that it should cut through more quickly, he begins measuring from the bottom of the drift or tunnel, at a point beyond the spot at which the bottom of the shaft will arrive, when it has been sunk. When he has measured the part of the drift or tunnel up to the first shaft which connects with an upper drift, he measures the incline of this shaft by applying a hemicycle or orbis to the cord. Then in a like manner he measures the upper drift and the incline shaft which is sunk therein toward which a raise is being dug, then again all the cords are stretched in the surveyor's field, the last cord in such a way that it reaches the first, and then he measures them. From this measurement is known in what part of the drift or tunnel the raise should be made, and how many fathoms of vein remain to be broken through in order that the shaft may be connected.

I have described the first reason for surveying; I will now describe another. When one vein comes near another, and their owners are different persons who have late come into possession, whether they drive a tunnel or a drift, or sink a shaft, they may encroach, or seem to encroach, without any lawful right, upon the boundaries of the older owners, for which reason the latter very often seek redress, or take legal proceedings. The surveyor either himself settles the dispute between the owners, or by his art gives evidence to the judges for making their decision, that one shall not encroach on the mine of the other. Thus, first of all he measures the mines of each party with a basket rope and cords of linden bark; and having applied to the cords an orbis or a compass, he notes the directions in which they extend. Then he stretches the cords on the surveyor's field; and starting from that point whose owners are in possession of the old meer toward the other, whether it is in the hanging or footwall of the vein, he stretches a crosscord in a straight line, according to the sixth division of the compass, that is, at a right angle to the vein, for a distance of three and a half fathoms, and assigns to the older owners that which belongs to them. But if both ends of one vein are being dug out in two tunnels, or drifts from opposite directions, the surveyor first of all considers the lower tunnel or drift and afterward the upper one, and judges how much each of them has risen little by little. On each side strong men take in their hands a stretched cord and hold it so that there is no point where it is not strained tight; on each side the surveyor supports the cord with a rod half a fathom long, and stays the rod at the end with a short stick as often as he thinks it necessary. But some fasten cords to the rods to make them steadier. The surveyor attaches a suspended plummet level to the middle of the cord to enable him to calculate more accurately on both sides, and from this he ascertains whether one tunnel has risen more than another, or in like manner one drift more than another. Afterward he measures the incline of the shafts on both sides, so that he can estimate their position on each side. Then he easily sees how many fathoms remain in the space which must be broken through. But the grade of each tunnel, as I said, should rise one fathom in the distance of one hundred fathoms.

The Swiss surveyors, when they wish to measure tunnels driven into the highest mountains, also use a rod half a fathom long, but composed of three parts, which screw together, so that they may be shortened. They use a cord made of linden bark to which are fastened slips of paper showing the number of fathoms. They also employ an instrument peculiar to them, which has a needle; but in place of the waxed circles they carry in their hands a chart on which they inscribe the readings of the instrument. The instrument is placed on the back part of the rod so that the tongue, and the extended cord which runs through the three holes in the tongue, demonstrates the direction, and they note the number of fathoms. The tongue shows whether the cord inclines forward or backward. The tongue does not hang, as in the case of the suspended plummet level, but is fixed to the instrument in a half-lying position. They measure the tunnels for the purpose of knowing how many fathoms they have been increased in elevation; how many fathoms the lower is distant from the upper one; how many fathoms of interval is

Indicator of a suspended plummet level

not yet pierced between the miners who on opposite sides are digging on the same vein, or cross-stringers, or two veins which are approaching one another.